D770-17-00 3 I56-986-00

Adjustments To Factory Settings

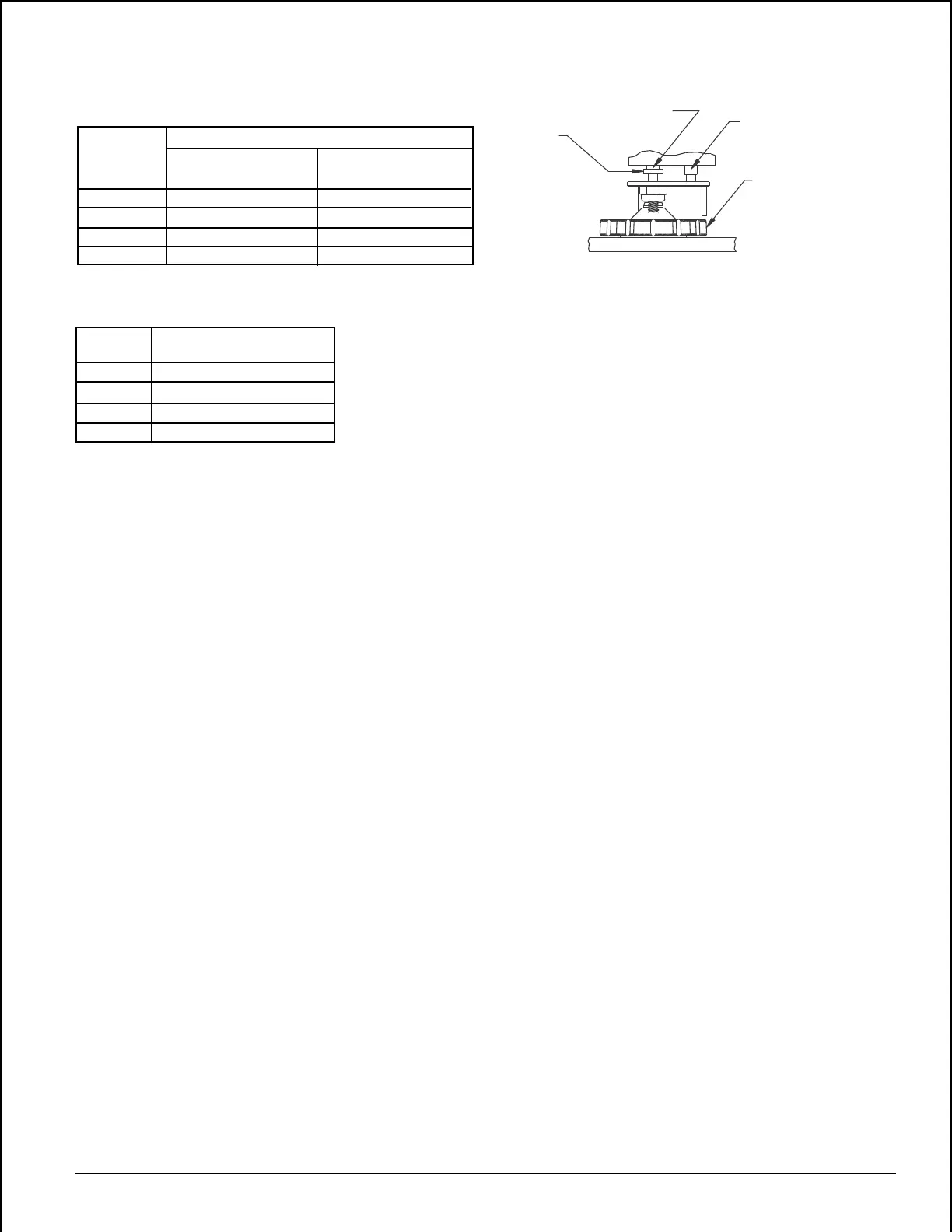

Table 2.

FACTORY SETTINGS (PSI)

MODEL

Fall

(Low Switch)

Rise

(Hi Switch)

EPS40-1

EPS40-2

EPS120-1

EPS120-2

30± 1.5

30± 1.5

––

105 - 110

105 - 110 120 - 125

––

50± 2.5

Table 3.

FIELD SETTINGS (PSI)MODEL

EPS40-1

EPS40-2

EPS120-1

EPS120-2

10-100

10-100

10-200

10-200

Single-switch Model — EPS40-1 and EPS120-1

1. Install pressure switch as stated in “INSTALLATION”

portion of instruction manual. Attach pressure test

source to system.

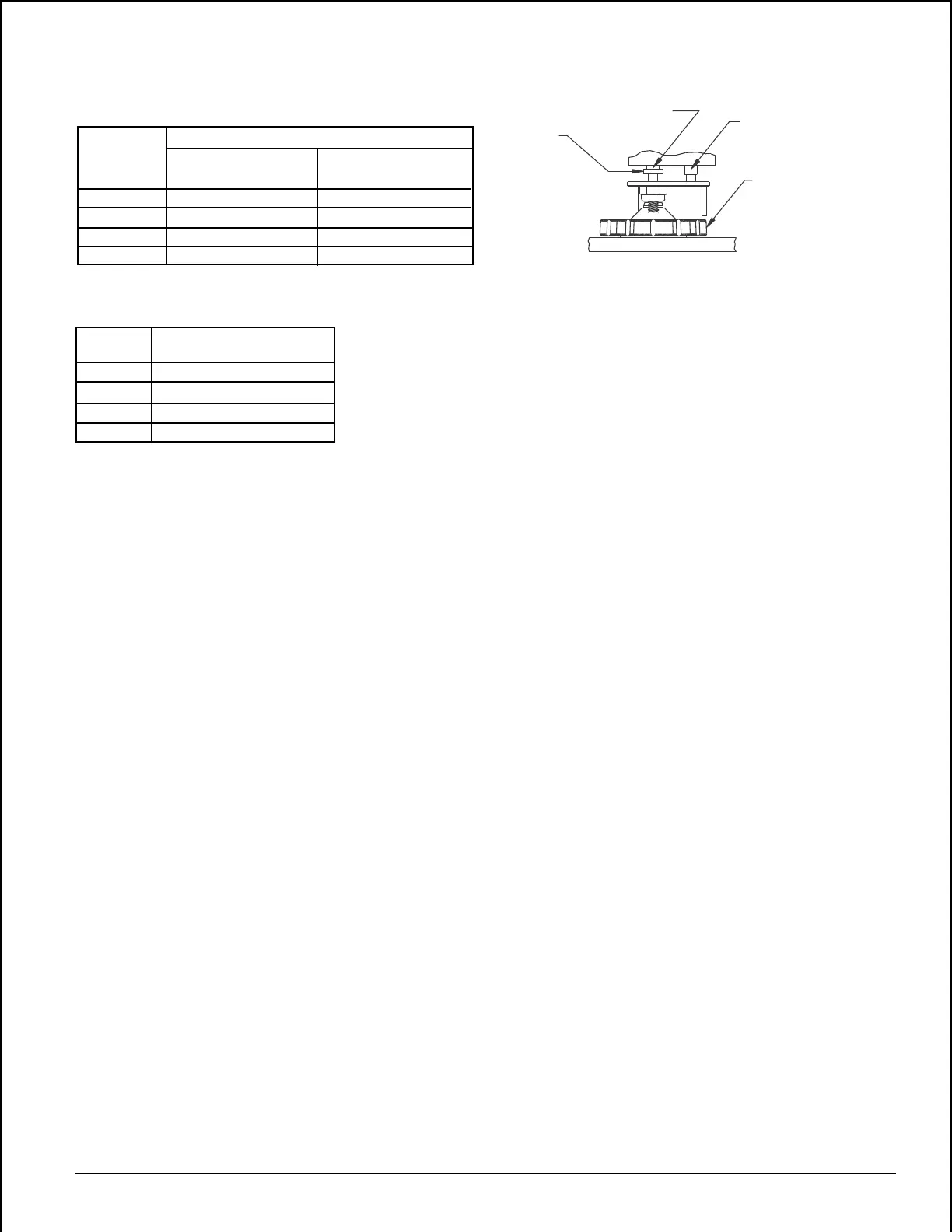

2. Back off locking screw (see Figure 1) to allow main ad-

justment wheel to rotate freely.

3. Test the switch for the set point by introducing 40 PSI

pressure from the pressure test source for the EPS40-1

(115 PSI for the EPS120-1). Decrease pressure slowly un-

til the switch trips. Rotate adjustment wheel (counter-

clockwise to increase pressure) and retest by first

introducing a higher pressure than desired and slowly

reducing pressure until the switch trips. Repeat process

until switch trip point is at desired pressure setting. The

approximate sensitivity of the adjustment wheel: 1/2

turn = 11 PSI for the EPS40-1; 1/2 turn = 40 PSI for the

EPS120-1.

4. Retest the set point several times to ensure accuracy of

setting.

5. Re-seat locking screw.

Dual-switch Model — EPS40-2 and EPS120-2

1. Install pressure switch as stated in “INSTALLATION”

portion of instruction manual. Attach pressure test

source to system.

2. Back off locking screw (see Figure 1) to allow main ad-

justment wheel to rotate freely.

3. Option 1: To adjust the nominal setting of the pressure

window (low switch setting to high switch setting) with-

out affecting the size of the window, adjust the main ad-

justment wheel to the desired setting using the pressure

source to verify each switch setting. The approximate

sensitivity of the adjustment wheel: 1/2 turn = 11 PSI

for the EPS40-2; 1/2 turn = 40 PSI for the EPS120-2.

Option 2: To adjust the pressure window size and the

nominal setting of the pressure window, adjust the main

adjustment wheel until the high switch (SW1) trips at

the desired pressure using the pressure test source. De-

crease the pressure until the low switch (SW2) trips.

Note pressure and determine how much change is de-

sired on the low switch. Adjust the 1/4" hex screw to ei-

ther increase (counterclockwise) or decrease

(clockwise) the window size. (The low switch will be af-

fected.) The approximate sensitivity of the hex screw ad-

justment: 1/2 turn = 5 PSI. An approximate maximum

window size of 30 PSI is obtainable within the differen-

tial limits stated on page 1. Retest the high switch after

adjusting the low switch.

4. Retest the set points several times to ensure the accuracy

of the settings.

5. Re-seat locking screw.

NOTE: The sensor assembly is not field replaceable. Do

not attempt to disassemble these parts. If you have

any questions, consult System Sensor. System Sen-

sor recommends careful consideration of the fol-

lowing factors when specifying and installing

Alarm and Supervisory Pressure Switches. Always

refer to the Installation and Maintenance Instruc-

tion for specific recommendations on individual

devices before installing the unit.

ADJUSTING

SCREW

1/4" HEX HEAD

(NOT PRESENT IN

SINGLE SWITCH

MODELS)

MAIN ADJUSTING WHEEL

(TURN COUNTERCLOCKWISE

TO INCREASE PRESSURE)

SWITCH 2

(LOW SWITCH

EPS40-2 AND

EPS120-2)

SWITCH 1

(HIGH SWITCH

EPS40-2 AND EPS120-2;

LOW SWITCH EPS40-1)

Figure 5. Adjustments (Dual-switch model shown):

A78-2347-00

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...