7

GB IE

Maintenance, Service and Repair

Always refer to Safety information above before

maintenance, service or repair. Before switching off the fan,

make sure that no EX atmosphere is present. The fan should

be cleaned when necessary, at least 1/year to avoid

imbalance and unnecessary damage to the bearings.

Bearing should be tested against discordant sounds. The

lifespan of the bearings are dependent on running time and

temperature, but should last for at least 40 000 hours.

Replace bearings when the grease has dried out, contact the

supplier. On single phase fans there is a piece of sticky tape

that covers the ventilation openings. If broken the capacitor

must be replaced by a Systemair personnel. A filter will

prolong the time interval between each cleaning of the fan.

Do not use a high-pressure cleaner (steam jet) when

cleaning the fan. Make sure the fan impeller's balance

weights are not moved or the fan impeller distorted. Listen for

abnormal operating noise. Make sure the fan has not been

blocked or that the motor protection has tripped.

Outdoor fans: If a fan is stationary for long periods in a humid

atmosphere, it should be switched On for a minimum of two

hours every week to remove any moisture that may have

condensed.

Repair or exchange of components is not allowed for

ATEX approved products.

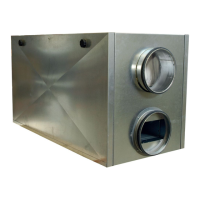

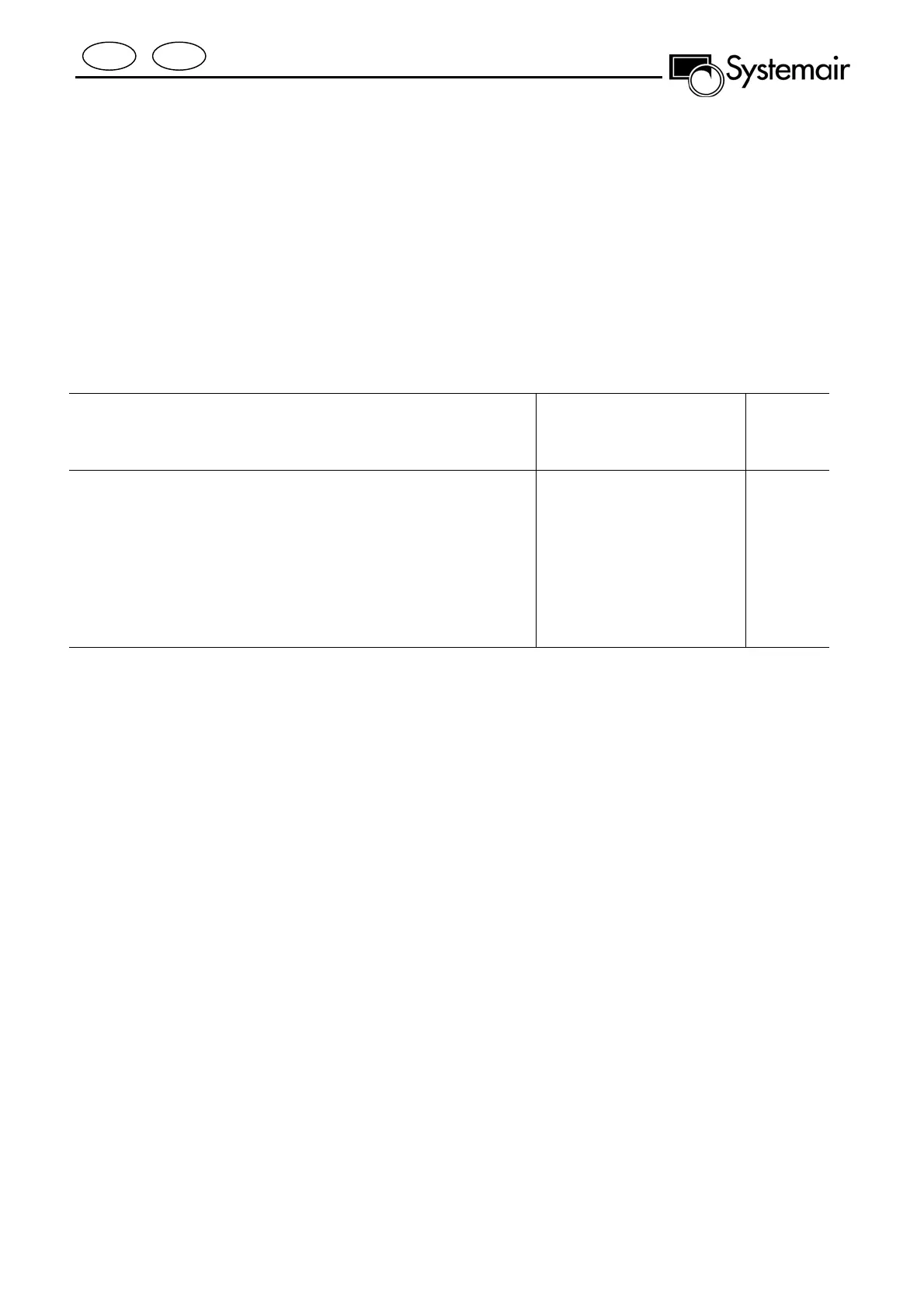

Table 1

*

1

) The current may exceed the currents on the nameplate by the ratio (%) given only as long as the total power

consumption does not exceed the value given on the nameplate.

*

2

) Step 1 2 3 4 5

Voltage 230V3~ 80 105 130 160 230

Voltage 400V3~ 90 140 180 230 400

Nameplate Nameplate I

max

Nameplate Min. static back pressure (Pa) Wiring

voltage current when

regulated

power Step

1

*

2

Step

2

Step

3

Step

4

Step

5

diagram

Model (V) (A) (%) *

1

) (kW) Page 2

DVEX 315D4 400V3~ 0,23 0 0,12 (Y)

DVEX 315D4 230V3~ 0,4 0 0,12 (D)

DVEX 355D4 230V3~/400V3~ 0,81/0,47 12 0,26 (D)/(Y)

DVEX 400D4 230V3~/400V3~ 1,31/0,76 12 0,39 (D)/(Y)

DVEX 450D4 230V3~/400V3~ 2,46/1,42 6 0,72 (D)/(Y)

DVEX 500D6 230V3~/400V3~ 1,50/0,87 0 0,38 (D)/(Y)

DVEX 560D6 230V3~/400V3~ 2,13/1,23 5 0,62 (D)/(Y)

DVEX 630D6 230V3~/400V3~ 3,72/2,15 0 1,07 (D)/(Y)

a

b

c

d

e

f

g

h

i

Explanation name plate, Fig. 3

- EU Free trade

- Notified body number for SP

- Logo for explosion proof material

- Explosion group II (also IIA, IIB and IIC)

- Category 2 ~ zone 1 ~ Flammable material present occasionally during normal usage. Additional sign placed

over the name plate has The products item number/ manufacture number/ date for manufacturing.

- Explosion proof material

- Certificate number

- Temperature class, max. surface temperature for fan 200 degrees can be used for gas mixtures with ignition

temperature exceeding 200

°C

- Class of protection ~ high safety

Loading...

Loading...