H PISTON FILLERS/STUFFERS

EN-29

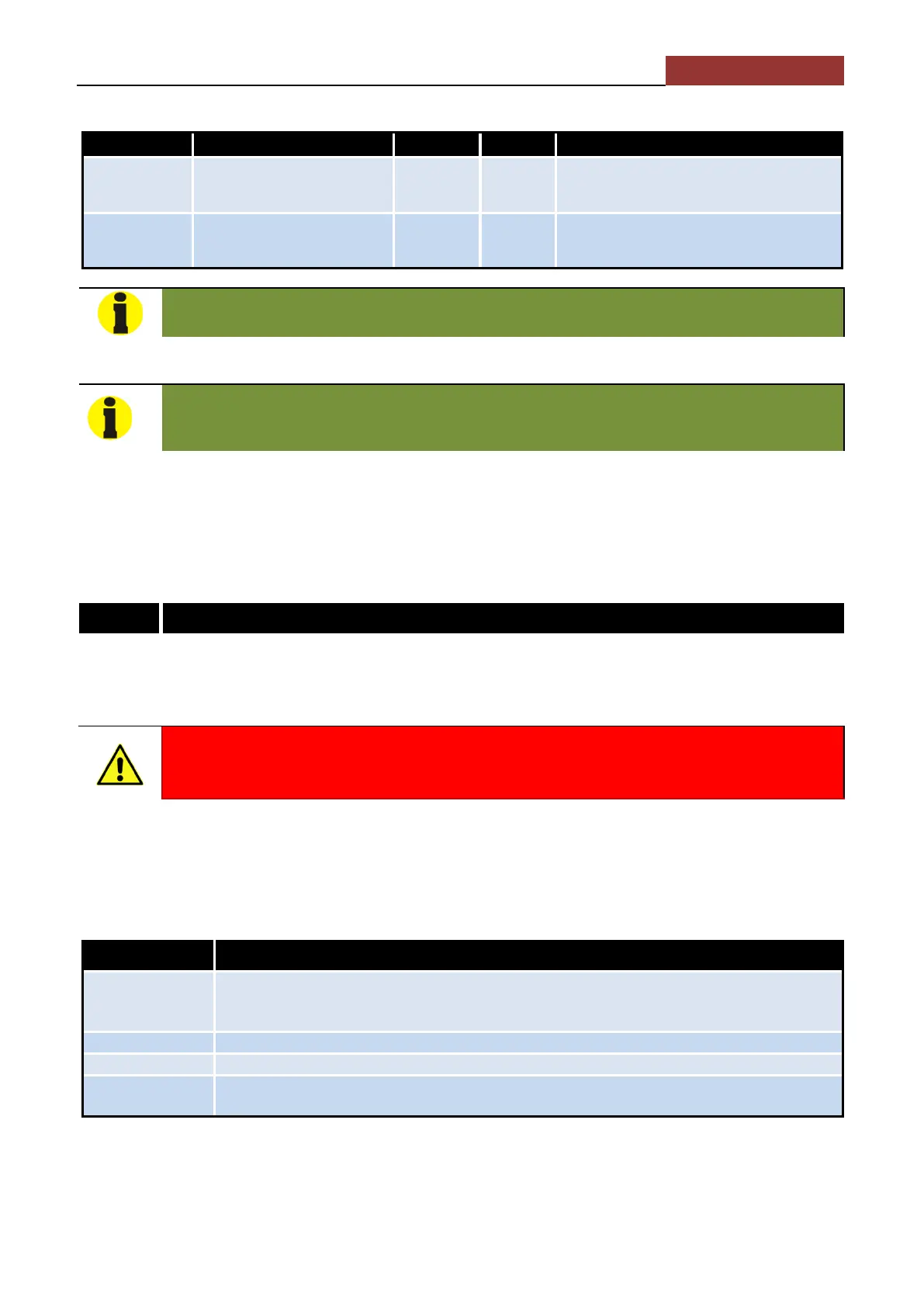

7.5 Recommended Intervals for Manual Cleaning

Underside of the lid, lid gasket,

interior of barrel and piston bolt

retaining screw*.

Mild

detergent,

warm water

Remove food residue from retaining screw using

a brush if necessary. Avoid buildup of residues.

Piston, piston gaskets and gasket

of piston bolt retaining screw.

Mild

detergent,

warm water

To remove the piston, follow the instructions

above.

The piston bolt retaining screw must be dismantled in order to be cleaned thoroughly.

7.6 Stainless Steel Care

Never use aggressive cleaners with stainless steel such as bleach or similar chlorine derivatives products. If

you have used it, never leave acting, rinse immediately with plenty of water and dry thoroughly.

It is uncommon, but possible, that small traces of rust or oxidation points may be observed on the machine. This may be due to:

■ Welding impurities.

■ Food fragments adhering to the surface.

■ Pits resulting from use of aggressive cleaners such as bleach or similar chlorine derivatives products.

■ Moisture that remains after cleaning with water. ALWAYS wipe dry all components that have been cleaned.

To remove these rust spots simply use a liquid stripper with a cloth, or clean with Scotch Brite.

Breakdowns resulting from infrequent or improper maintenance can lead to expensive repairs, lost productivity due to down time and

could void our warranty; therefore, regular and adequate maintenance is indispensable. The safety and life of the machine depend on

many factors, including proper maintenance.

ALWAYS unplug the machine before proceeding with maintenance and inspection.

ALWAYS follow the safety instructions in this manual during maintenance and inspection operations.

Although it is difficult to give specific advice regarding inspection, maintenance or parts replacement schedules since these depend

on many variables related to the machine’s use, we can make some recommendations. The user, however, is solely responsible for

formulating and following an inspection and maintenance schedules that reflect the machine’s actual use.

Our local distributor will be delighted to provide you with further information.

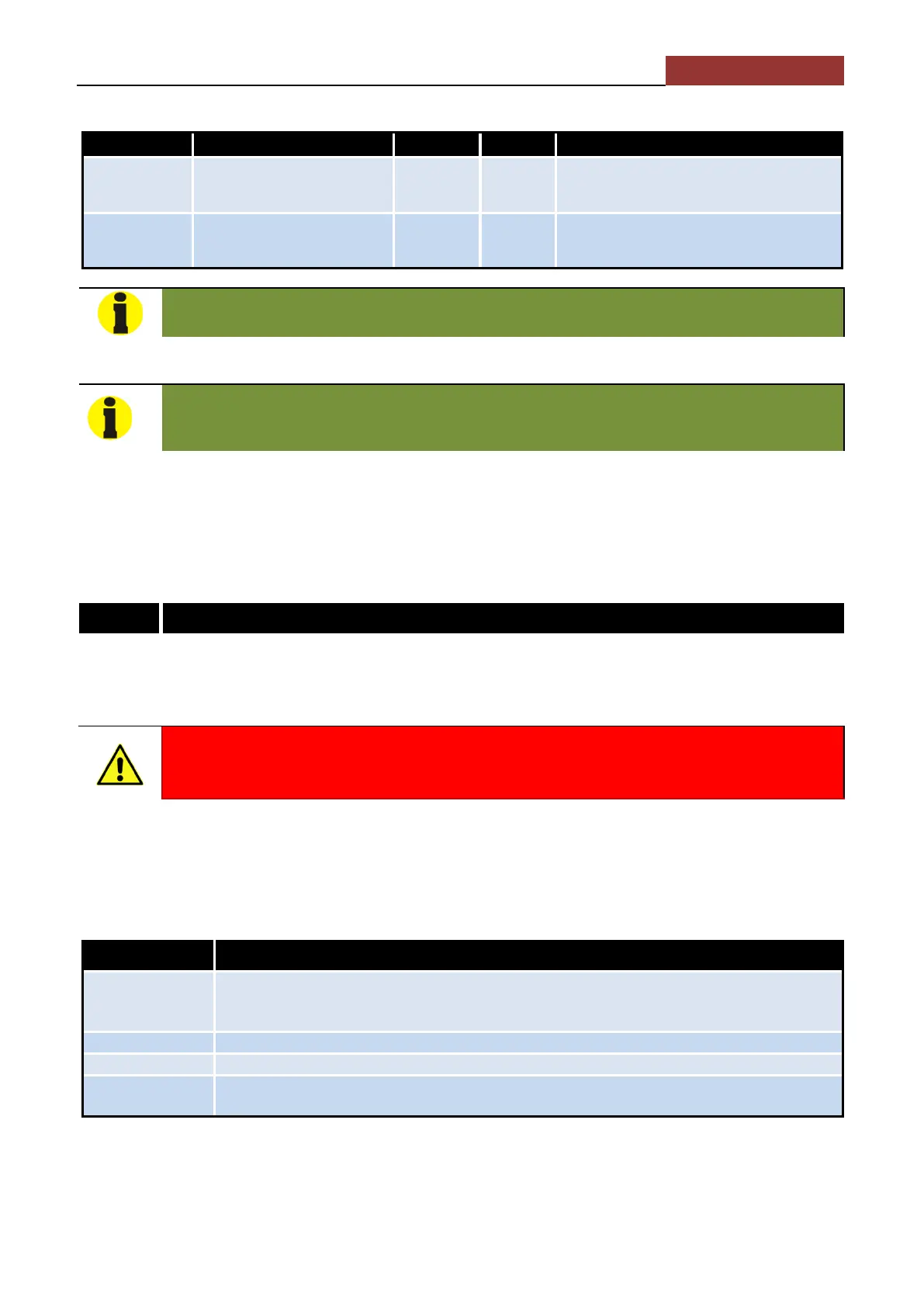

8.1 Suggested Inspection & Maintenance Schedule

Component / Maintenance Information

Check the green lid gasket and replace it if necessary.

Check the two black piston gaskets and replace them if necessary.

Check the air holes at the base of the barrel and clear them of any obstruction.

Check how tightly the lid closes and adjust the lid fixing bolts as necessary (P models only).

Check the hydraulic oil level and add oil to the reservoir if necessary.

Every 2500 - 5000

service hours

Drain the hydraulic oil and refill.

Check the oil filter and replace if necessary.

Please note: These inspection & maintenance recommendations are for a machine used during one shift per workday.

www.talsaparts.com

www.davisonsbutcher.com

Loading...

Loading...