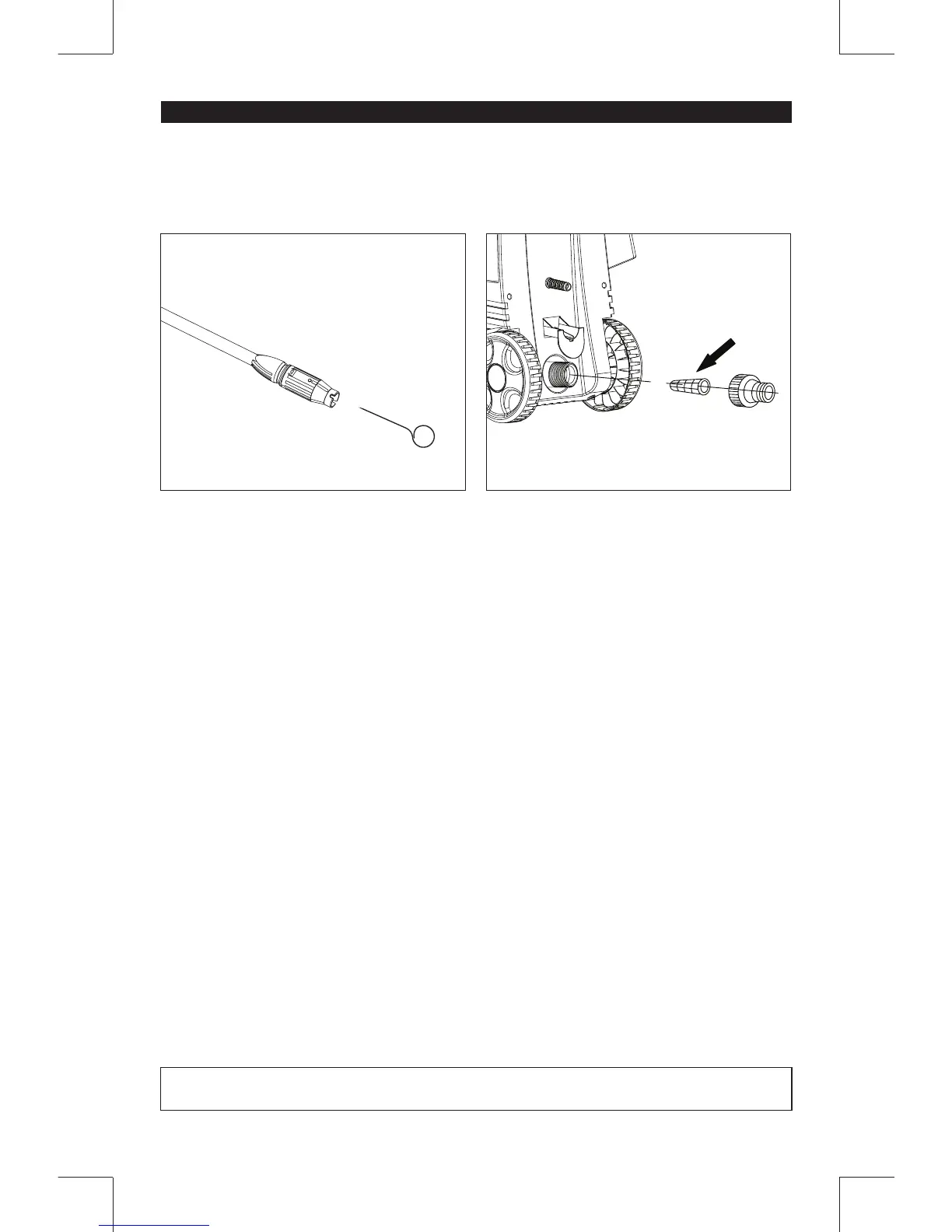

Water Filter Screen (Fig. 16)

The pressure washer is equipped with a water inlet

lter (L) that prevents debris going into the pump.

If the lter is not kept clean, the ow of water to the

pressure washer will be restricted and the pump

may be damaged.

1. To clean the screen, remove quick connector and

remove the lter screen from the pump inlet.

2. Rinse screen until it is free of debris and blockage.

3. Replace screen and quick-connector immediately.

Air Vents

The air vents located on the front and back of the

pressure washer must be kept clean and free of any

obstructions to ensure proper air-cooling of the mo-

tor during operation.

Fig. 16

SERVICING SHOULD BE PERFORMED BY AN AUTHORIZED SERVICE REPRESENTATIVE. CHECK WITH YOUR

LOCAL RETAILERS FOR THE WARRANTY POLICY AND SERVICE OPTION.

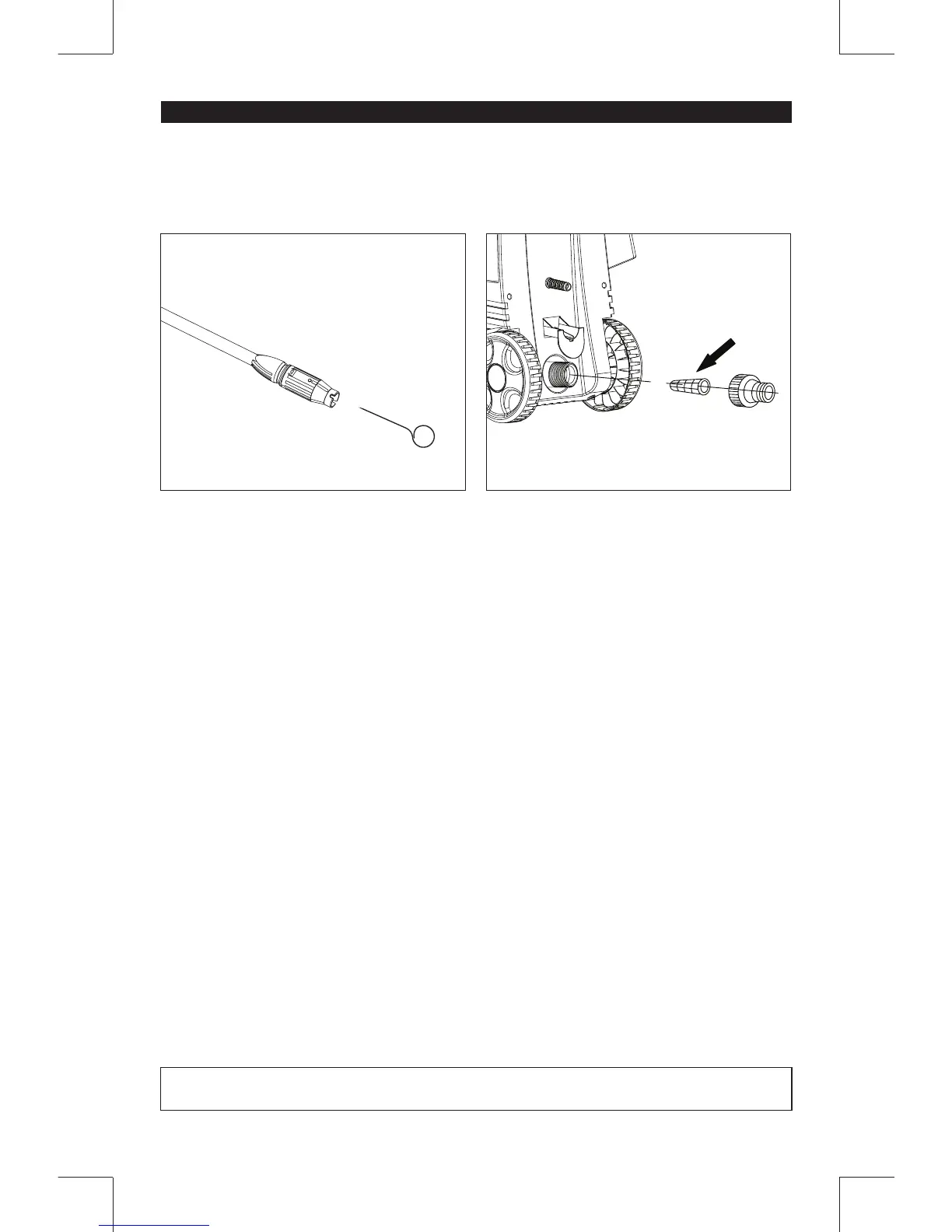

Adjustable Nozzle (Fig. 15)

When the nozzle is clogged, it will cause the pump to

build pressure and may cause the unit to surge. You

can clean the nozzle by inserting needle (N) into the

tip to rid it of the deposits.

For the adjustable nozzle, you can also lubricate the

nozzle collar (high-pressure low-pressure) by using

non-water soluble grease regularly.

Loading...

Loading...