Confidential and proprietary information contained in this repair guide is subject to change without notice.

Distribution, transfer, copy of any content or data in this document without the written permission of TCL is strictly prohibited.

9.3 Reassembly process and tools

Reassembly process is reverse order of the disassembly process. But there are some precaution as

follow:

1) Double-side sponge tape, Battery packing pet, all types of adhesive on battery cover must be

replaced with new ones once it is disassembled.

Conductive cloth, high temperature adhesive, double-side adhesive tape, or other adhesive are

selectively replaced, depend on breakage, stickiness conditions.

➢ The battery-package-film (PN: 286806003) must be swap with new ones for the assembly.

Note: The adhesive must be clean before assembly.

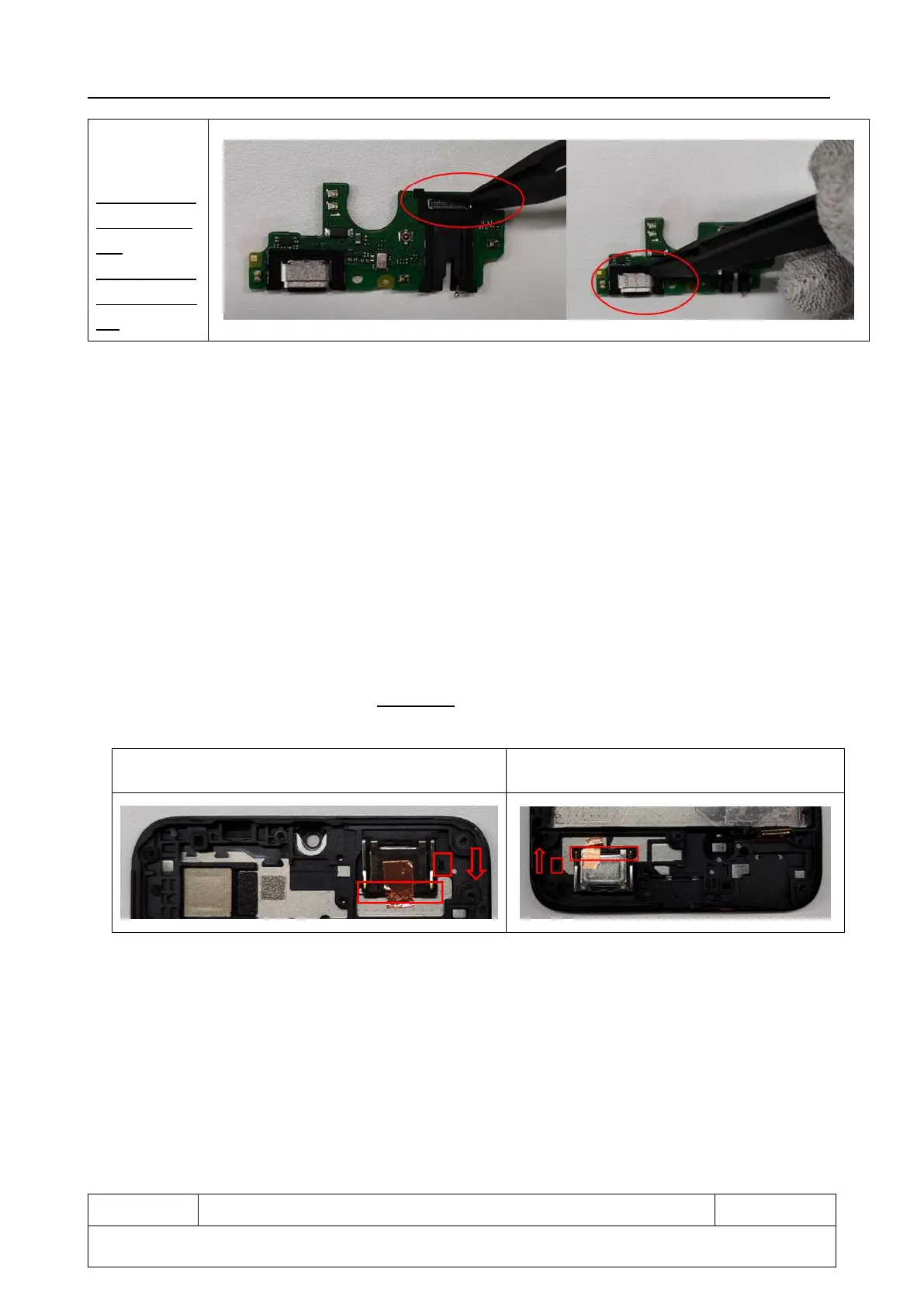

2) Pay attention to the direction of the SPRAKER (Please install the GRAPHITE_FOR_LOW_SPK

and GRAPHITE_FOR_upp_SPK).

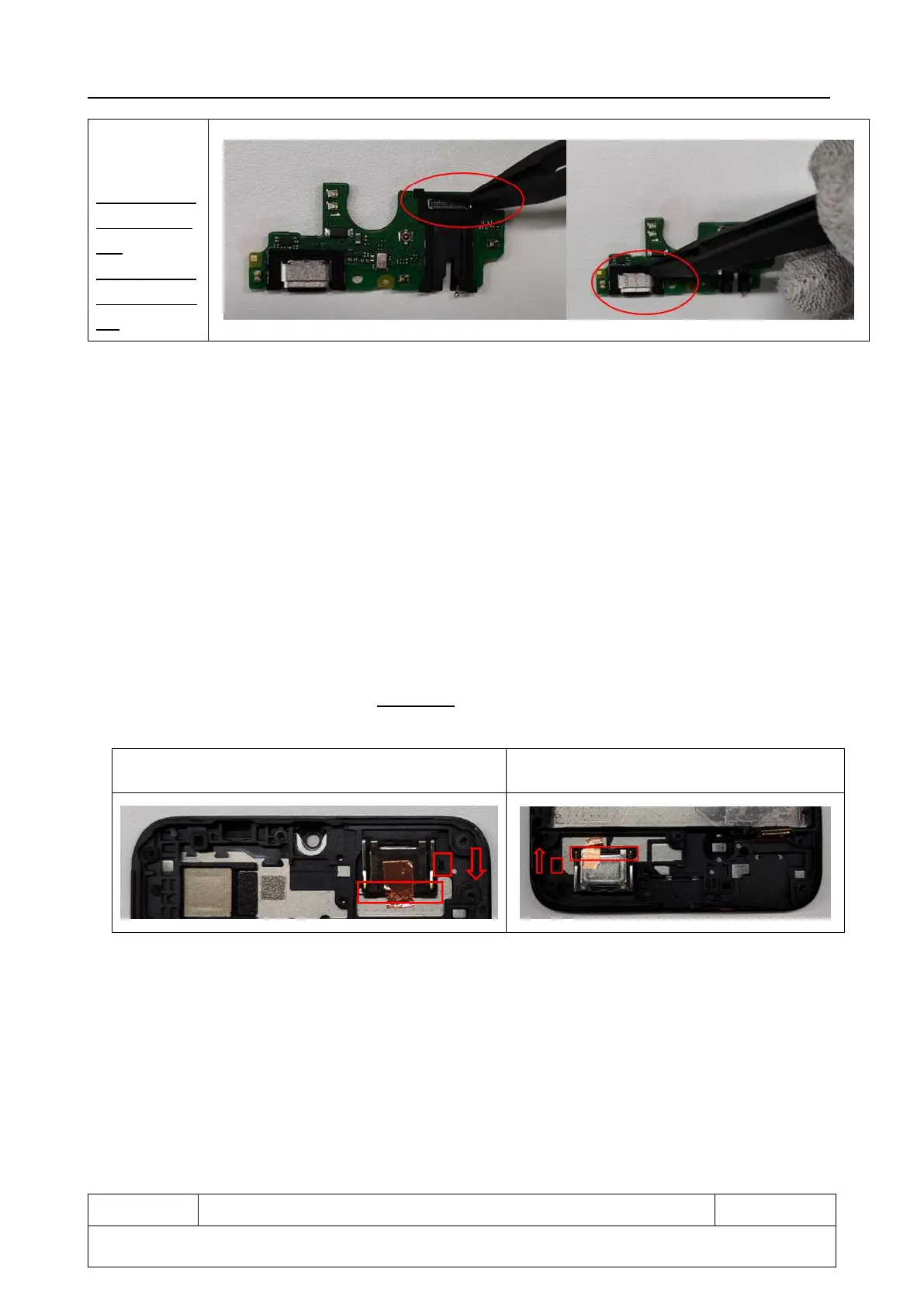

3) There is “Thermal Gel” between main PCBA and TP-frame-pre-assembly. If a new main PCBA or

TP-frame-pre-assembly or both of them were repalced, new thermal gel should be filled.

Loading...

Loading...