※Contact TDK-Lambda concerning items not mentioned or items which are not clear.

5. Soldering Conditions / Cleaning Condi

5. Soldering Conditions / Cleaning Condi5. Soldering Conditions / Cleaning Condi

5. Soldering Conditions / Cleaning Conditions / Installation Method

tions / Installation Methodtions / Installation Method

tions / Installation Method

5-1 Soldering Conditions

【DIP Model】

Perform soldering of the converter to the board according to the conditions shown in Table 5-1.

Soldering is to be performed only one time per pin.

Table 5-1 Solder Conditions for DIP Models

Method Condition

Solder Dip 260℃ 10 sec Max.

Solder Iron 380℃ 3 sec Max.

【SMD Model】

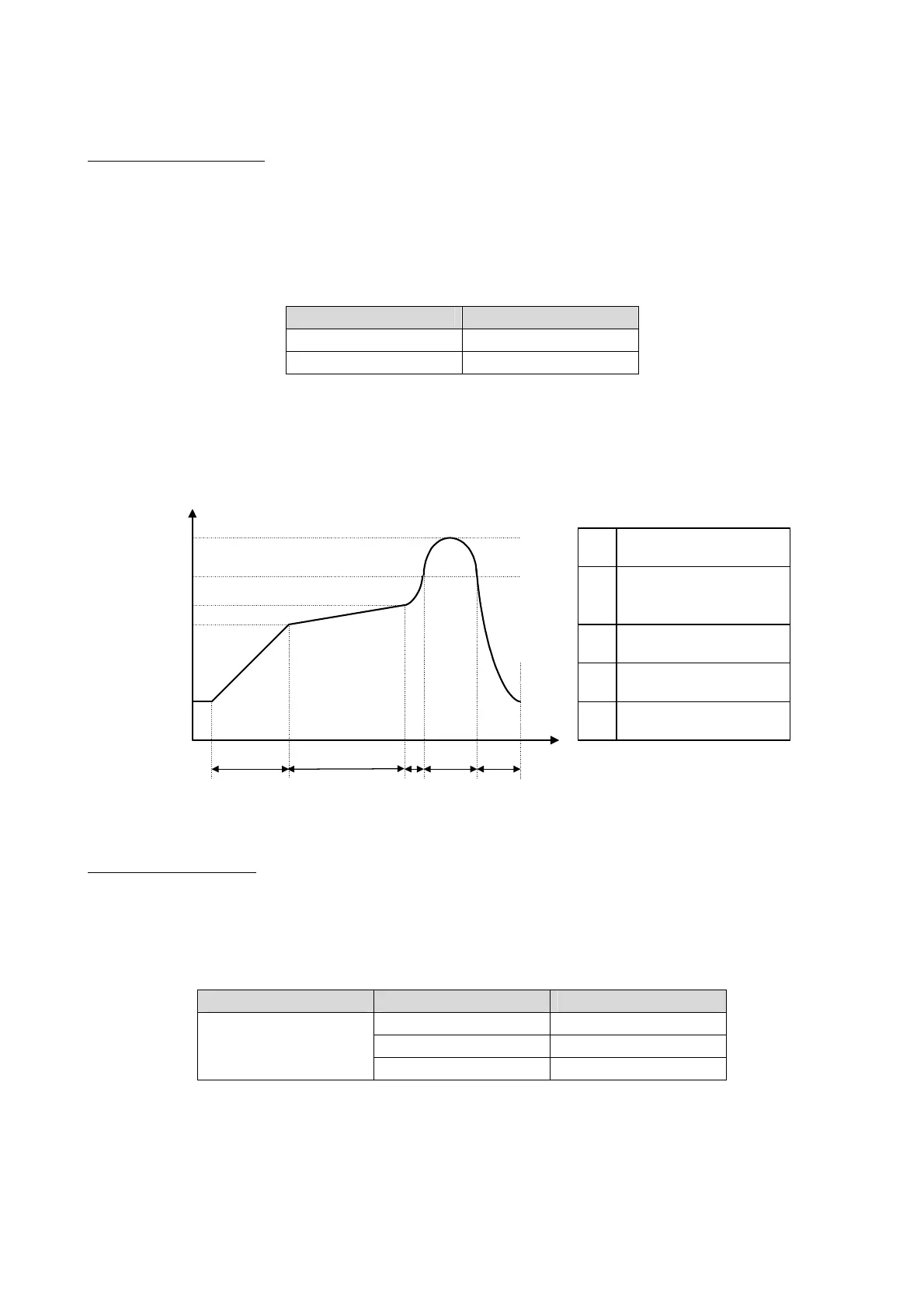

Lead free solder / high temperature reflow process conditions are shown in Figure 5-1.

The number of times permitted for reflow is 1 time.

TP

225

Ty2

Ty1

部品表面温度(℃)

ハンダ付け時間(s)

A 'A B B ' C

A

A '

B

B '

C

1.0~3.0℃/sec

Ty1:150±10℃

Ty2:170±10℃

Ty1~Ty2:20~100sec

1.0~4.0℃/sec

TP:MAX 245℃

225℃以上:20~40sec

-1.0~-5.0℃/sec

Fig. 5-1 Reflow Process Conditions for SMD Models

5-2 Washing Conditions

We do not recommend board cleaning after soldering, we recommend not performing cleaning, but when cleaning becomes

necessary, perform it according to the conditions shown in Table 5-2

Table 5-2 Cleaning Fluid and Test Conditions

Cleaning Fluid Cleaning Method Time

Ultrasonic Wave 60℃ 60 sec.

Cold Bath Cleaning R.T 60 sec.

Isopropyl Alcohol

Vapor Cleaning 83℃ 60 sec.

Loading...

Loading...