99

Stability problems

The speed control has a PID controller. It ensures an exact and fast adjustment of the

actual value to the set point.

In applications such as solar power systems or feed

pumps, the following parameters should be left in factory settings. With a few

exceptions, the system will run stably. These two values have to be balanced, however,

especially for hygienic hot water from the external heat exchanger. In addition, in this case

the use of an ultrafast sensor (non-standard accessory) is recommended at the hot water

outlet.

Set value = desired value Actual value = temperature measured

PRO 5 Proportional part of the PID controller 5. It represents the reinforcement of the

deviation between the desired and the actual value. The speed is changed by one

increment for each 0.

5K of deviation from the desired value. A large number leads

to a more stable system but also to more deviation from the predefined

temperature. (ex works = 5) Setting range: 0 to 100

INT 5 Integral part of the PID controller 5. It periodically adjusts the speed relative to the

deviation remaining from the proportional part. For each

1K of deviation from the

desired value, the speed changes one increment every

5 seconds. A large

number provides a more stable system, but it then takes longer to reach the

desired value. (ex works = 0) Setting range: 0 to 100

DIF 5 Differential part of the PID controller 5. The faster a deviation occurs between the

desired and the current value, the greater the short-term overreaction will be to

provide the fastest compensation possible. If the desired value deviates at a rate

of 0.

5K per second, the speed is changed by one increment. Large numbers

provide a more stable system, but it then takes longer to reach the desired value.

(ex works = 0) Setting range: 0 to 100

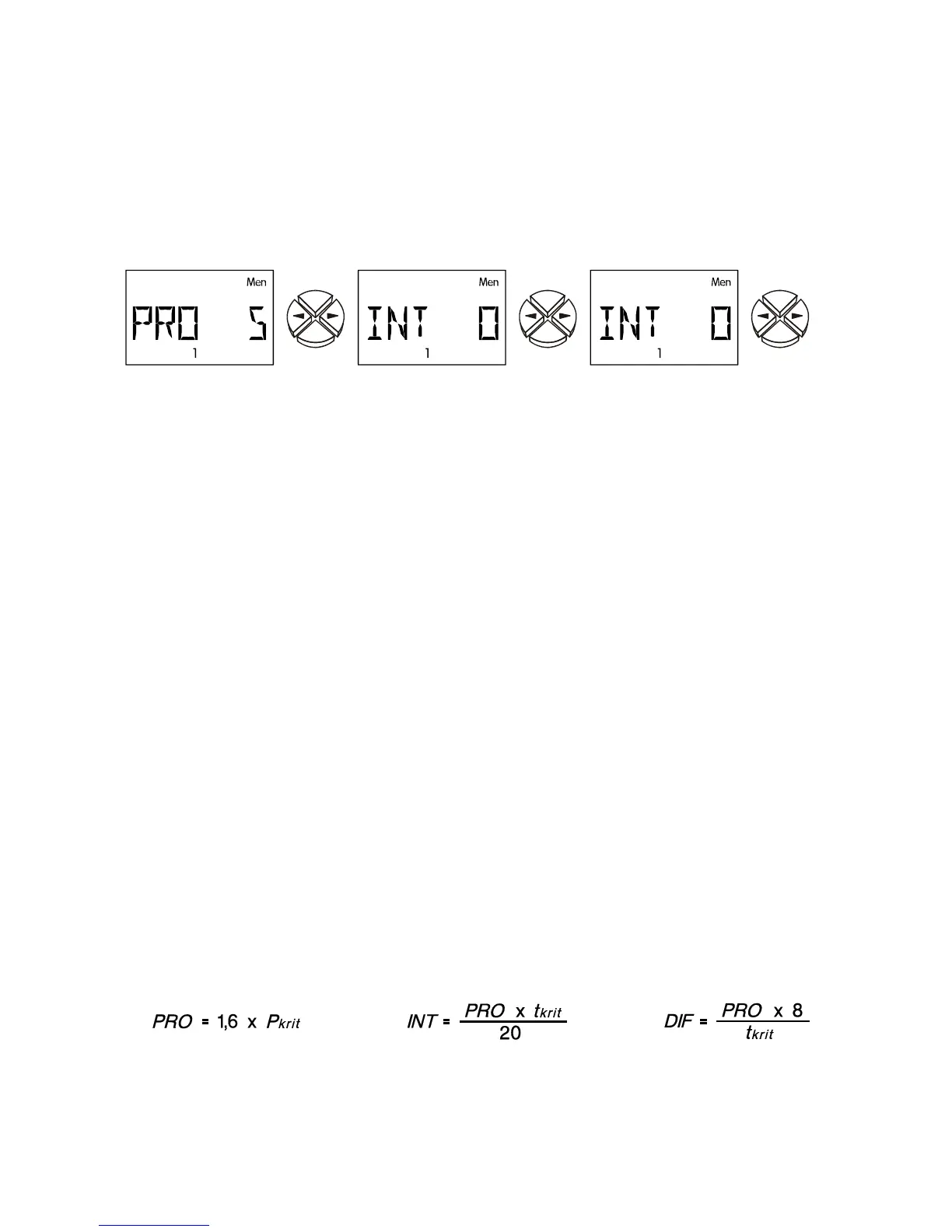

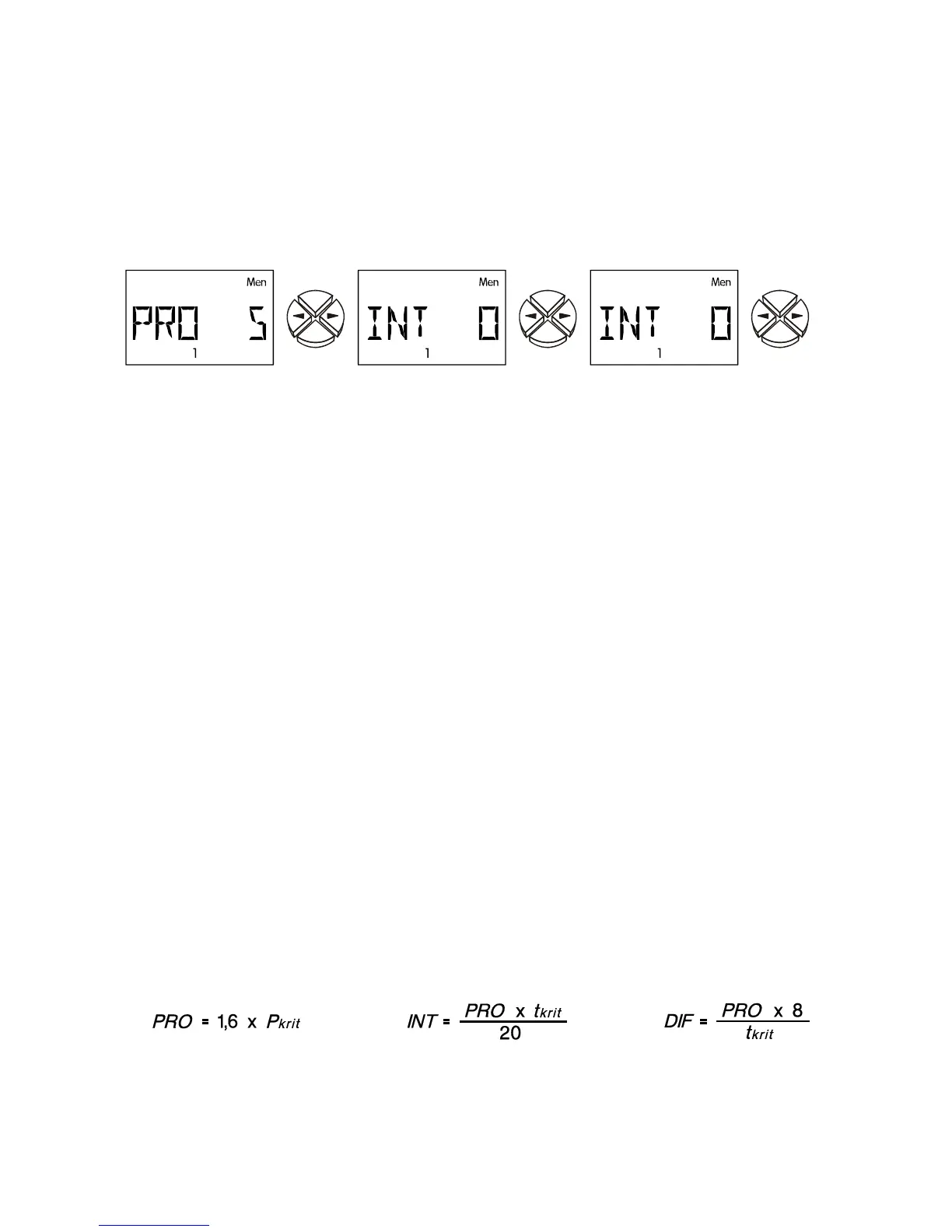

The parameters PRO, INT, and DIF can also be determined in a test: Assume that the

pump is running in automatic mode in a unit that is ready for operation with appropriate

temperatures. With INT and DIF set to zero (= switched off), PRO is reduced every 30

seconds starting at 9 until the system is instable. In other words, the pump speed changes

rhythmically and can be read in the menu with the command ACT. Every proportional part

that becomes instable is noted as P

krit

just as the duration of the oscillation (= time between

the two highest speeds) is noted as t

krit

. The following formulas can be used to determine the

correct parameters.

A typical result of hygienic service water with the ultrafast sensor is PRO = 8, INT = 9, DIF

= 3. For reasons not entirely understood, the setting PRO = 3, INT = 1, DIF = 4 has proven

practical. Probably, the control unit is so unstable that it oscillates very quickly and appears to

be balanced due to the system’s and the fluid’s inertia.

Loading...

Loading...