LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

13

regreasing operations, in the rst hours of motor operation, when the motor work out of the nominal conditios, in case of use, in maintinace operation, non

compliant graeses respect those indicated by the manufacturer.

These grease leakage should be monitored during the periodic motor inspection, any leakage should be cleaned with care and caution to avoid damage to

the environment. Persistenceof these leaks should be avoided because it indicates that the motor operates out to the nominal conditions, or that have been

used, during maintinance operations, not complying grease.

5.2.1 Machines with permanently greased bearings

Bearings are usually permanently greased bearings of 1Z, 2Z, 2RS or equivalent types.

As a guide, adequate lubrication for sizes up to 200 can be achieved for the following duration, according to L10, until 200 size.

Duty hours for permanently greased bearings at ambient temperatures of 25 and 40° C are:

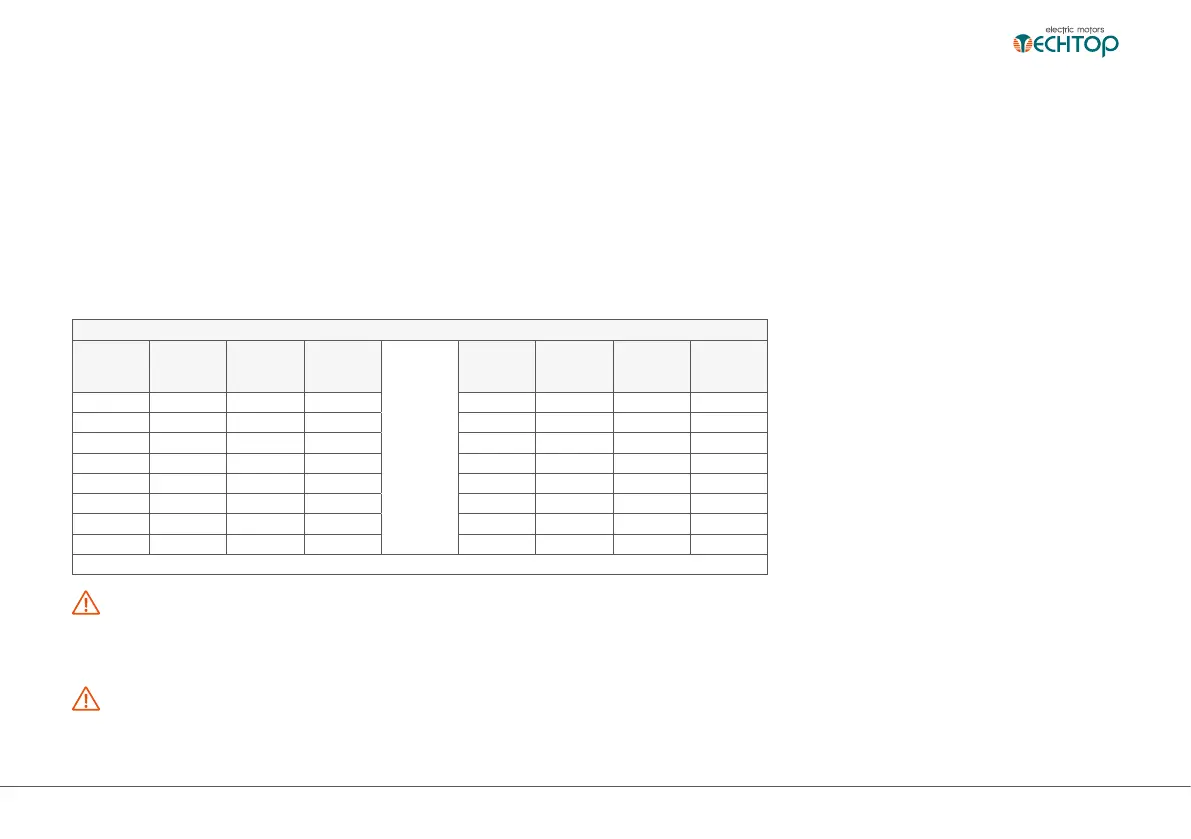

LUBRICATION INTERVALS ACCORDING TO L10 PRINCIPLE

Frame

Size

Poles

Duty

hours at

25°C

Duty

hours at

40°C

Frame

Size

Poles

Duty

hours at

25°C

Duty

hours at

40°C

56-63 2-8 40000 40000 132 4-8 40000 40000

71 2 40000 40000 160 2 40000 36000

71 4-8 40000 40000 160 4-8 40000 40000

80-90 2 40000 40000 180 2 38000 38000

80-90 4-8 40000 40000 180 4-8 40000 40000

100-112 2 40000 32000 200 2 27000 27000

100-112 4-8 40000 40000 200 4-8 40000 40000

132 2 40000 27000

*Data valid at 50 Hz, for 60 Hz reduce values for 20 %.

WARNING!

These values are valid for permitted load values given in the product catalog. Depending on application and load conditions, see the applicable product

catalog or contact TECHTOP. Data above reported will be in compliance with item 5.2, and are refered at the following motor working conditions, ambient

temperature 25°C, max bearing working temperature 80°C. Medium bearing lifetime value showed should be halved for each increment of 15°C of the

ambient temperature.

WARNING!

With the aim to keep the stated average lifetime it is important to perform periodical inspections on the motor, in order to prevent temperature increases on

the bearings due to eventual dirt accumulating on the motor housing or on the ventilation system.

Loading...

Loading...