LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

20

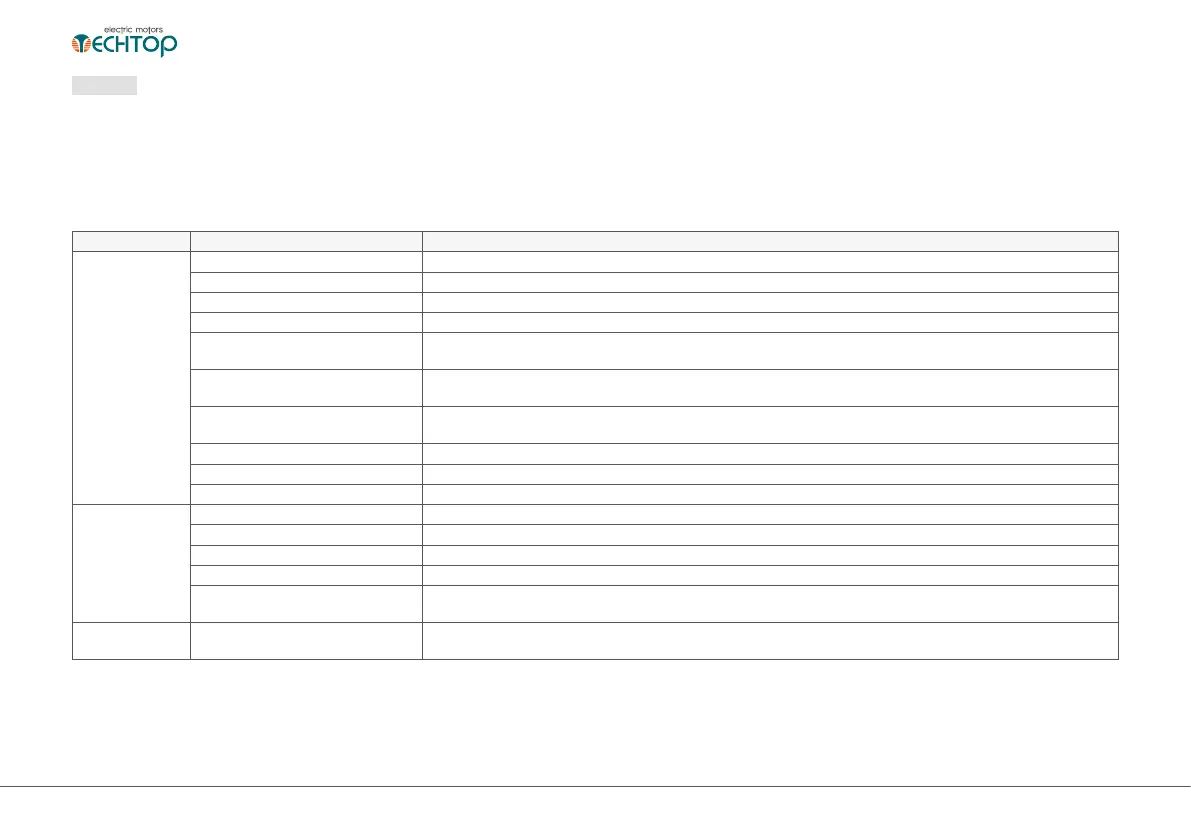

8. TROUBLESHOOTING

These instructions do not cover all details or variations in equipment nor provide for every possible condition to be met in connection with installation,

operation or maintenance.

Motor troubleshooting chart

Your motor service and any troubleshooting must be handled by qualied persons who have proper tools and equipment.

TROUBLE CAUSE SOLUTION

Motor fails to

start

Blown fuses Replace fuses with proper type and rating

Overload trips Check and reset overload in starter

Improper power supply Check to see that power supplied agrees with motor rating plate and load factor

Improper line connections Check connections against diagram supplied with motor

Open circuit in winding or

control switch

Indicated by humming sound when switch is closed. Check for loose wiring connections.

Also ensure that all control contacts are closing

Mechanical failure

Check to see if motor turn freely.

Check bearings and lubrication

Short circuited stator

Indicated by blown fuses.

Motor must be rewound

Poor stator coil connection Remove end shields, locate fault

Rotor defective Look for broken bars or end rings

Motor may be overloaded Reduce load

Motor stalls

One phase may be open Check lines for open phase

Wrong application Change type or size,consult equipment supplier

Overload Reduce load

Low voltage Ensure the rating plate voltage is maintained,check connection

Ooen circuit Fuses blown, check overload relay, stator and push buttons

Motor runs and

then dies down

Power failure Check for loose connections to line, to fuses and to control

Loading...

Loading...