LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

15

– In this case use only half the quantity of grease and then run the motor for a few minutes at full speed.

– When the motor has stopped, apply the rest of the specied amount of grease to the bearing.

– After 1-2 running hours close the grease outlet plug.

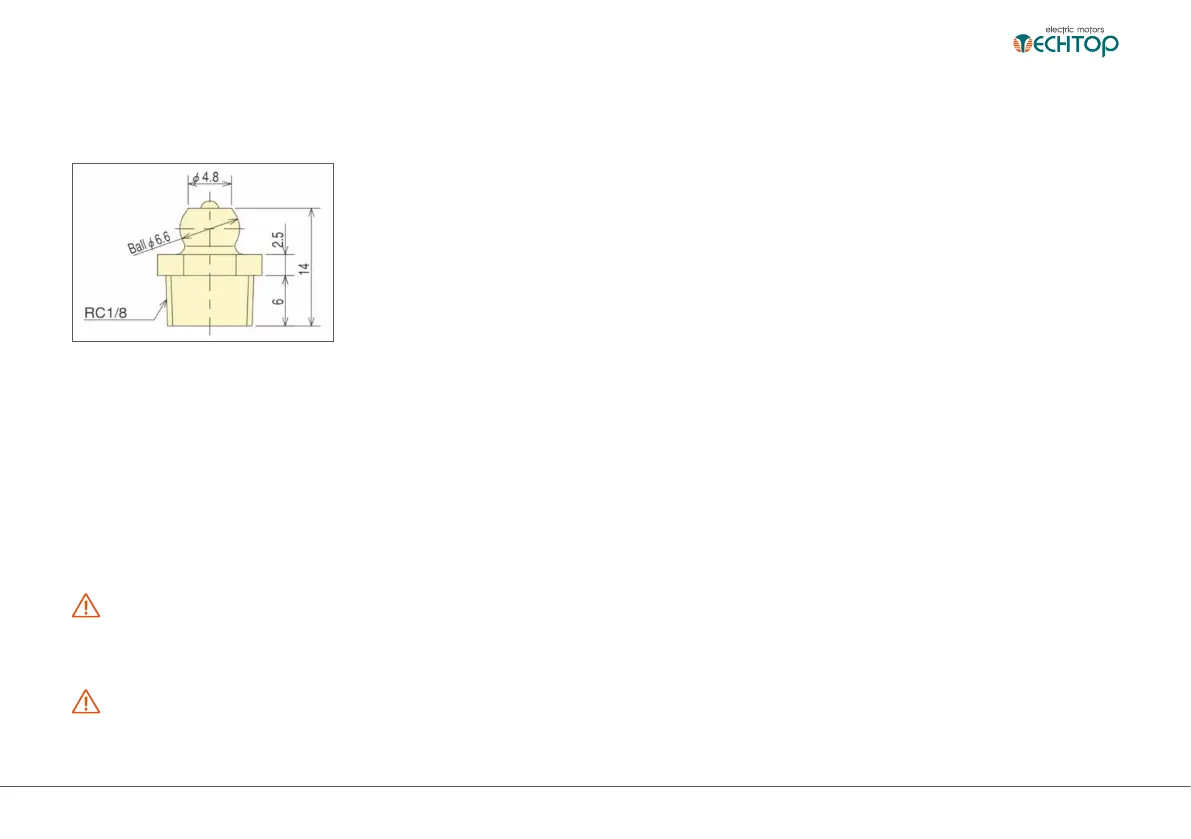

Greasing nipple dimension (mm)

B. Automatic lubrication

The grease outlet plug must be removed permanently with automatic lubrication.

TECHTOP recommends only the use of electromechanical systems.

The amount of grease per lubrication interval stated in the table should be multiplied by four if an automatic regreasing system is used.

When 2-pole motors are automatically regreased, the note concerning lubricant recommendations for 2-pole motors in the Lubricants chapter should be

followed.

5.2.3 Lubrication intervals and amounts

As a guide, adequate lubrication for motors with regreasable bearings can be achieved for the following duration, according to L1. For duties with higher

ambient temperatures please contact TECHTOP. The formula to change the L1 values roughly to L10 values: L10 = 2.7 x L1.

WARNING!

Lubrication intervals for vertical machines are half of the values shown in the table below.

The lubrication intervals are based on an ambient temperature +25°C. An increase in the ambient temperature raises the temperature of the bearings

correspondingly. The values should be halved for a 15°C increase and may be doubled for a 15°C decrease.

WARNING!

The maximum operating temperature of the grease and bearings, +110°C, must not be exceeded. The designed maximum speed of the motor must not be

exceeded.

Loading...

Loading...