LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

21

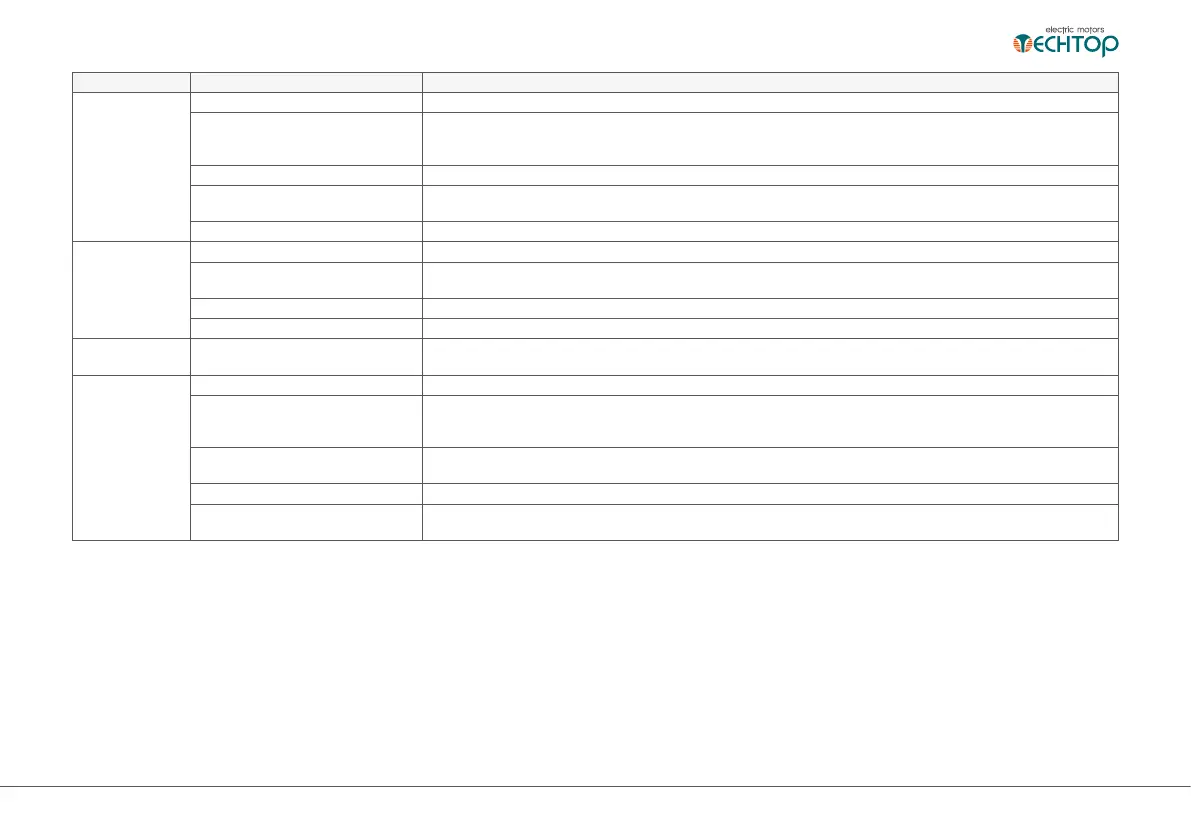

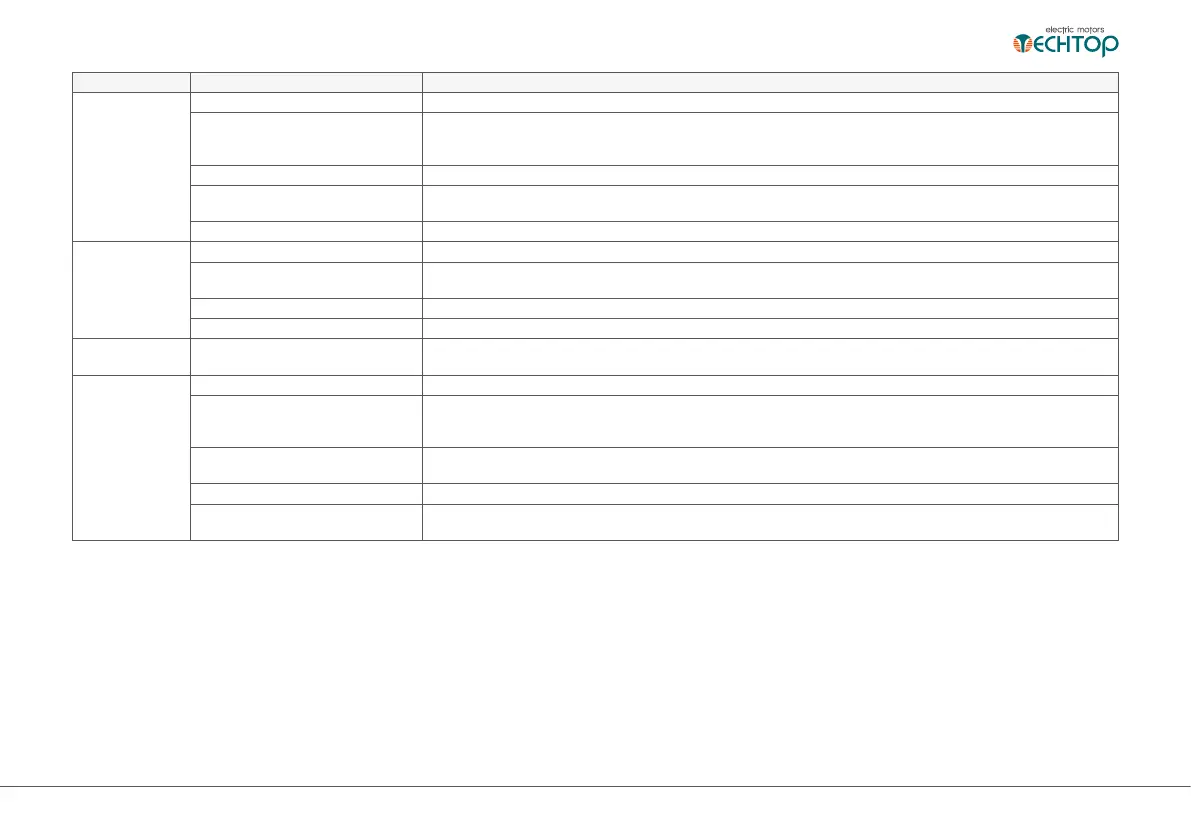

TROUBLE CAUSE SOLUTION

Motor does not

come up to

nominal speed

Not applied properly Consult equipment supplier for proper type

Voltage too low at motor

terminals because of line drop

Use higher voltage or transformer terminals or reduce load, check connections, check conductors for

proper size

Starting load too high Check the start load of the motor

Broken rotor bars or loose rotor Look for cracks near the rings,a new rotor may be required, as repairs are usually temporary

Open primary circuit Locate fault with testing device and repair

Motor takes

too long to

accelerate and/

or draws high

current

Excessive load Reduce load

Low voltage during start Check for high resistance,make sure that adequate cable size is used

Defective squirrel cage rotor Replace with new rotor

Applied voltage too low Correct power supply

Wrong rotation

direction

Wrong sequence of phases Reverse connections at motor or at switchboard

Motor overheats

while running

Overload Reduce load

Frame or ventilation openings

may be full of dirt and prevent

proper ventilation of motor

Open vent holes and check for a continuous stream of air from the motor

Motor may have one phase open Check to make sure that all leads are well connected

Grounded coil Motor must be rewound

Unbalanced terminal voltage Check for faulty leads, connections and transformers

Loading...

Loading...