By using par. “InE” it is also possible to decide the conditions of

the input error, allowing the instrument to give the power

programmed on par. “OPE” as output.

The possibilities of par. “InE” are :

= Or : the condition occurs in case of over-range or probe breakage

= Ur : the condition occurs in case of under-range or probe

breakage

= Our : the condition occurs in case of over-range or under-range

or probe breakage

Using par. “diSP”, located in the group “

]

PAn”, it is possible to set

normal visualization of the display which can be the process

variable (dEF), the control power (Pou), the active Set Point (SP.F)

the Set Point operating when there are active ramps (SP.o) or

alarm threshold AL1, AL2 or AL3 (AL1, AL2, AL3).

Again in the group “

]

PAn” the par. “AdE” is present that defines

the 3 led shift index functioning.

The lighting up of the green led = indicates that the process value

is within the range [SP+AdE ... SP-AdE], the lighting up of the led –

indicates that the process value is lower than [SP-AdE] and the

lighting up of the led + indicates that the process value is higher

than [SP+AdE].

4.2 - OUTPUTS CONFIGURATION

The instrument’s outputs can be programmed by entering the group

of parameters “

]

Out, where the relative parameters “O1F”, “O2F”

and “O3F” (depending on the number of outputs available on the

instrument) are located.

The outputs can be set for the following functions :

- Main control output (1.rEG)

- Secondary control output (2.rEG)

- Alarm output normally open (ALno)

- Alarm output normally closed (ALnc)

- Alarm output normally closed with led reverse indication (ALni)

- Output deactivated (OFF)

The coupling outputs number outputs – number alarms can be

made in the group referring to the alarm to the alarm (“

]

AL1”, “

]

AL2”,

“

]

AL3”).

4.3 - ON/OFF CONTROL (1.rEG)

All the parameters referring to the ON/OFF control are contained in

the group “

]

rEG”.

This type of control can be obtained by programming par."Cont" =

On.FS or = On.FA and works on the output programmed as 1.rEG,

depending on the measure, on the active Set Point “SP”, on the

functioning mode "Func” and on the hysteresis "HSEt".

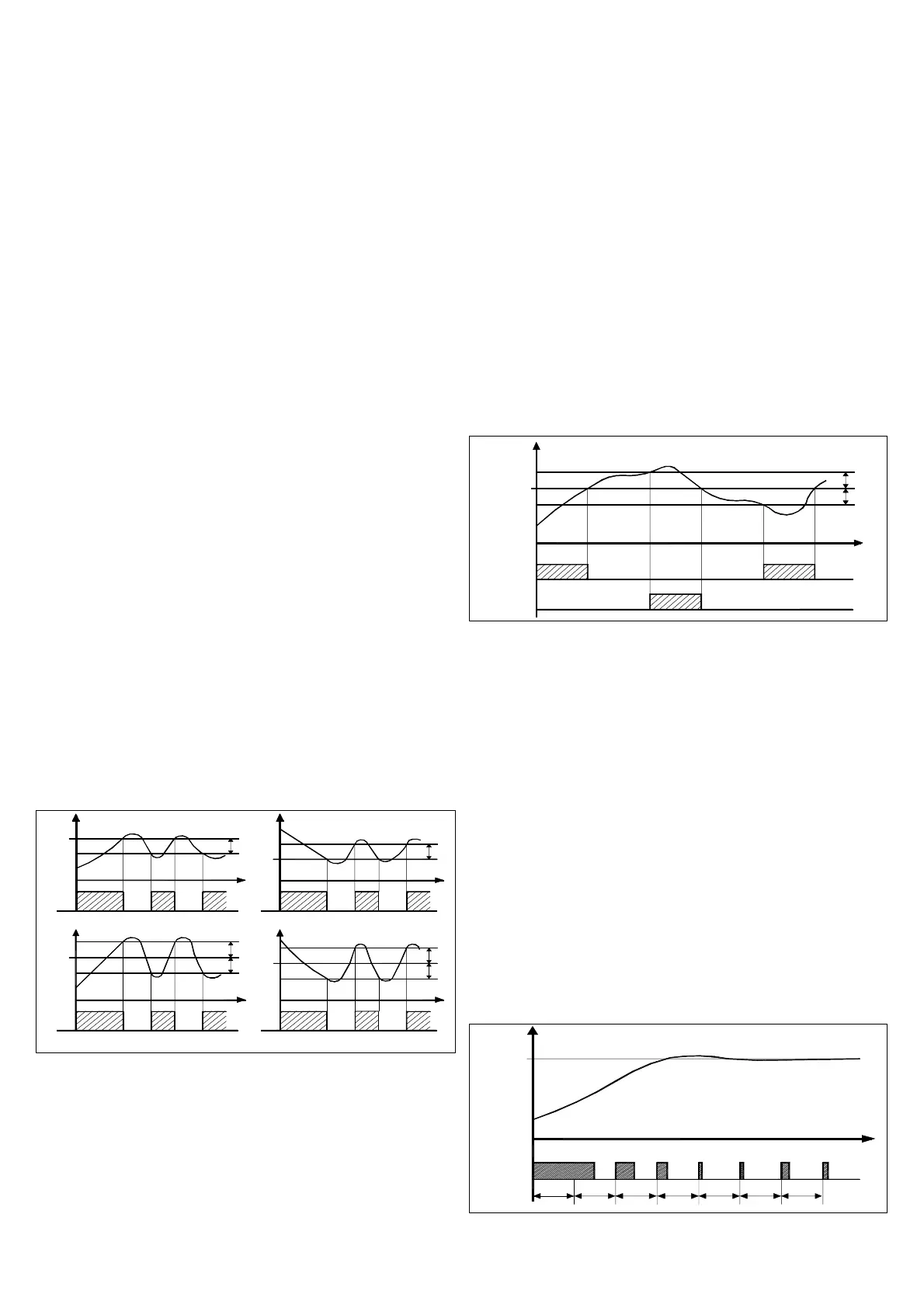

The instrument carries out an ON/OFF control with symmetric

hysteresis if “Cont" = On.FS or with asymmetrical hysteresis if

“Cont” = On.FA.

OUT

SP

PV

off

ON

HEAt - On.FA

OUT

time

HSEt

SP

PV

HSEt

time

C oo L - O n .FA

ON ON ON ON ON

off off off

CooL - On.FSHEAt - On.FS

ONON

OUT

SP

off

PV

off

ON

HSEt

time

OUT

ON

SP

PV

ON

off off

ON

time

HSEt

HSEt

HSEt

1.rEG 1.rEG

1.rEG1.rEG

The control works in the following way : in the case of reverse

action, or heating (“FunC”=HEAt), it deactivates the output, when

the process value reaches [SP + HSEt] in case of symmetrical

hysteresis, or [SP] in case of asymmetrical hysteresis and is then

activated again when the process value goes below value [SP -

HSEt].

Vice versa, in case of direct action or cooling ("Func”=CooL), it

deactivates the output, when the process value reaches [SP -

HSEt] in case of symmetrical hysteresis, or [SP] in case of

asymmetrical hysteresis and is activated again when the process

value goes above value [SP + HSEt].

4.4 - NEUTRAL ZONE ON/OFF CONTROL (1.rEG - 2.rEG)

All the parameters referring to Neutral Zone ON/OFF control are

contained in the group “

]

rEG”.

This type of control can be obtained when 2 outputs are

programmed respectively as 1.rEG and 2.rEG and the par. “Cont”

= nr .

The Neutral Zone control is used to control plants in which there is

an element which causes a positive increase (ex. Heater,

humidifier, etc.) and an element which causes a negative increase

(ex. Cooler, de-humidifier, etc).

The control functions works on the programmed outputs depending

on the measurement, on the active Set Point “SP” and on the

hysteresis "HSEt".

The control works in the following way : it deactivates the outputs

when the process value reaches the Set Point and it activates the

output 1.rEG when the process value goes below value [SP -

HSEt], or it activates the output 2.rEG when the process value goes

above [SP + HSEt].

Consequently, the element causing a positive increase has to be

connected to the output programmed as 1.rEG while the element

causing a negative increase has to be connected to the output

programmed as 2.rEG.

0N

OUT 2.rEG

(cooling)

OUT 1.rEG

(heating)

SP

PV

off

0N

off

off

off

0N

time

HSEt

HSEt

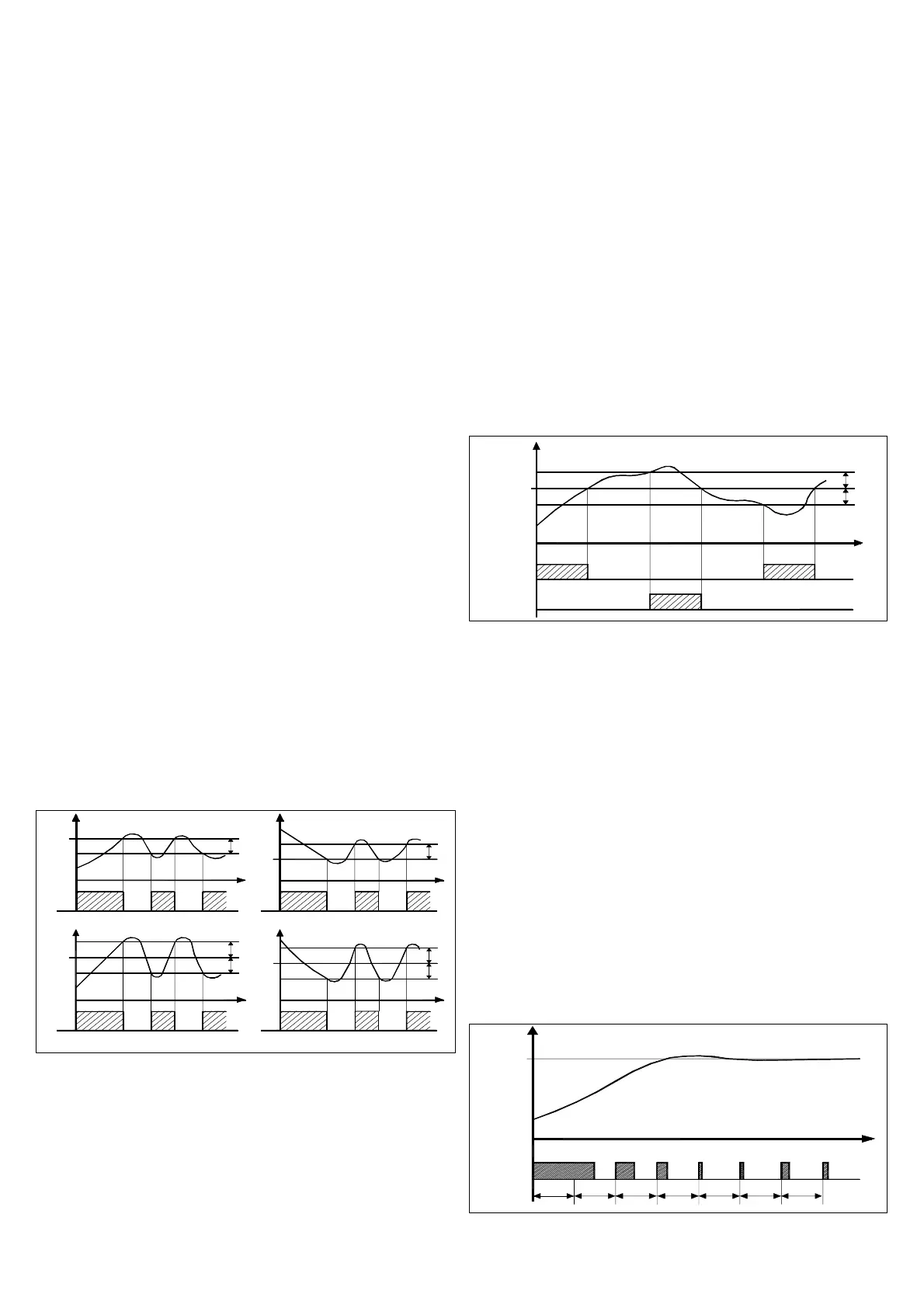

If 2.rEG output is used to control compressor is possible to use the

“Compressor Protection” function that has the meaning to avoid

compressor “short cycles”.

This function allows a control by time on the output 2.rEG

activation, independently by the temperature control request.

The protection is a “delayed after deactivation” type.

This protection permits to avoid the output activation for a time

programmable on par. “CPdt” (expressed in sec.); the output

activation will occurs only after the elapsing of time “CPdt”.

The time programmed on parameter “CPdt” is counted starting from

the last output deactivation.

Obviously, whether during the time delay caused by the

compressor protection function, the regulator request should stop,

the output activation foreseen after time “CPdt” would be erased.

The function is not active programming “CPdt” =OFF.

The led relative to 2.rEG output blinks during the phases of output

activation delay, caused by “Compressor Protection” function.

4.5 - SINGLE ACTION PID CONTROL (1.rEG)

All the parameters referring to PID control are contained in the

group “

]

rEG”.

The Single Action PID control can be obtained by programming

par."Cont" = Pid and works on the output 1.rEG depending on the

active Set Point “SP”, on the functioning mode "Func” and on the

instrument’s PID algorithm with two degree of freedom.

0N

tc r1

1.rEG

(H E a t)

SP

PV

tcr1

off

tcr1tcr1tcr1 tc r1

0N

off off

0N

offoff

0N 0N

tcr1

off

0N 0N

tim e

OUT

TECNOLOGIC spa - TLK 48 - OPERATING INSTRUCTIONS - Vr. 03 - ISTR 06481 - PAG. 5

Loading...

Loading...