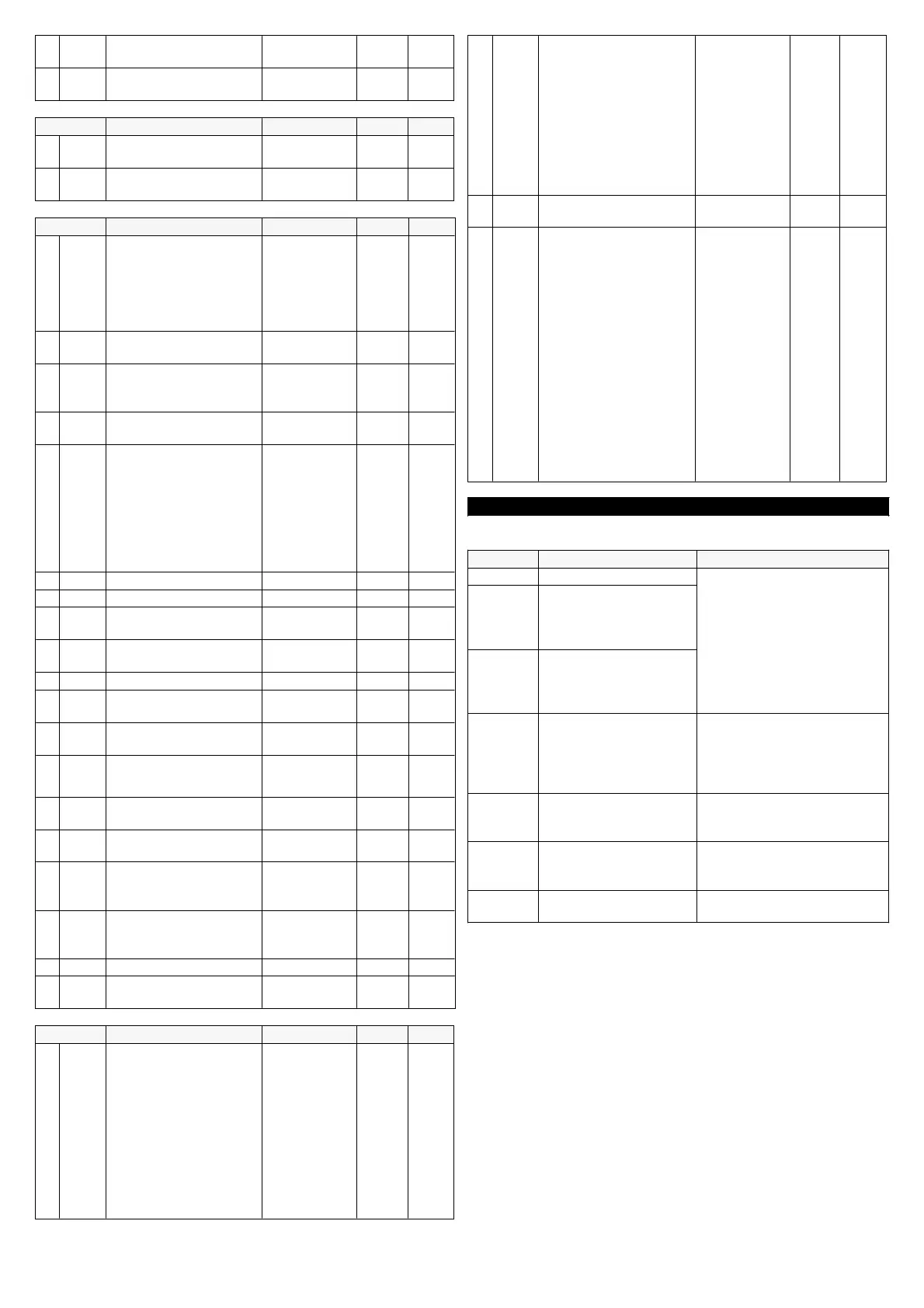

nono / yESAlarm AL3 activation in

case of measuring error

AL3i

48

OFFOFF ÷ 9999

sec.

Activation delay of

alarm AL3

AL3d

47

Group “

]

LbA” (parameters relative to Loop Break Alarm)

OFFOFF ÷ 9999

sec.

Time necessary to acti-

vate alarm LbA

LbA

50

OFFOut1 / Out2

Out3 / OFF

Output where alarm

LbA is addressed

OLb

49

NoteDef.RangeDescriptionPar.

Group “

]

rEG” (parameters relative to the control)

OFFOFF/0.1÷7.59

/ InF hrs.-min.

Soft-Start time

SSt

69

0-100 ÷ 100 %Soft-Start power

St.P

68

InF0.00 ÷ 99.99

/ InF

unit / min.

Gradient of second

ramp:

InF= Ramp not active

SLoF

67

InF0.00 ÷ 99.59

/ InF

hrs.-min.

Duration time between

two ramps

InF= Time not active

dur.t

66

InF0.00 ÷ 99.99

/ InF unit/min.

Gradient of first ramp :

InF= Ramp not active

SLo

65

0.0-100.0÷100.0

%

Manual reset

rS

64

10.00.1 ÷ 130.0

sec.

Cycle time of 2.rEG

tcr2

63

1.000.01 ÷ 99.99Power ratio 2.rEg /

1.rEG

Prat

62

20.00.1 ÷ 130.0

sec.

Cycle time of output

1.rEG

tcr1

61

0.50.00 ÷ 2.00Fuzzy overshoot control

FuOc

60

50OFF÷ 9999

sec.

Derivative time

dEr

59

200OFF ÷ 9999

sec.

Integral time

Int

58

500 ÷ 9999Proportional band

Pb

57

nono / yESSelftuning enable

SELF

56

2OFF /

1 / 2 / 3 / 4

Autotuning Fast enable

OFF = Not active

1 = Start each power on

2= Start at first power

on

3= Start manually

4= Start after Soft Start

or chang

Set Point

Auto

55

OFFOFF÷ 9999

sec.

Compressor Protection

time for 2.rEG

CPd

54

10 ÷ 9999Hysteresis of ON/OFF

control (or end Soft

Start cycle threshold)

HSEt

53

HEAtHEAt / CooLFunctioning mode

output 1.rEG

Func

52

PidPid / On.FA

On.FS / nr

Control type:

Pid= PID

On.FA= ON/OFF asym.

On.FS= ON/OFF sym.

nr= Neutral Zone

ON/OFF

Cont

51

NoteDef.RangeDescriptionPar.

Group “

]

PAn” (parameters relative to the user interface)

noFnoF / tunE /

OPLO / Aac /

ASi / CHSP /

OFF

Functioning of key “U” :

noF = No Function

tune= Start Autotuning

or Selftuning

OPLO= Manual Control

(open loop)

Aac= Reset Alarms

latch

ASi= Aknowledged

Alarms

OFF= Control OFF

USrb

70

NoteDef.RangeDescriptionPar.

SAESE / AE /

SAE / SAnE

Fast progr. Active Set

and alarms:

SE= Active Set can be

modified while the

alarm thresholds can-

not be modified

AE= Active Set cannot

be modified while the

alarm thresholds can

be modified

SAE= Active Set and

alarm thresholds can

be modified

SAnE= Active Set and

alarm thresholds can-

not be modified

Edit

73

2OFF...9999Shift value for the shift

index functioning

dE

72

dEFdEF / Pou /

SP.F / SP.o /

AL1 / AL2 /

AL3

Variable visualized on

the display:

dEF= Process Value

Pou= Control Power

SP.F= Active Set Value

SP.o = Operative Set

value

AL1 = AL1 threshold

AL2 = AL2 threshold

AL3 = AL3 threshold

diSP

71

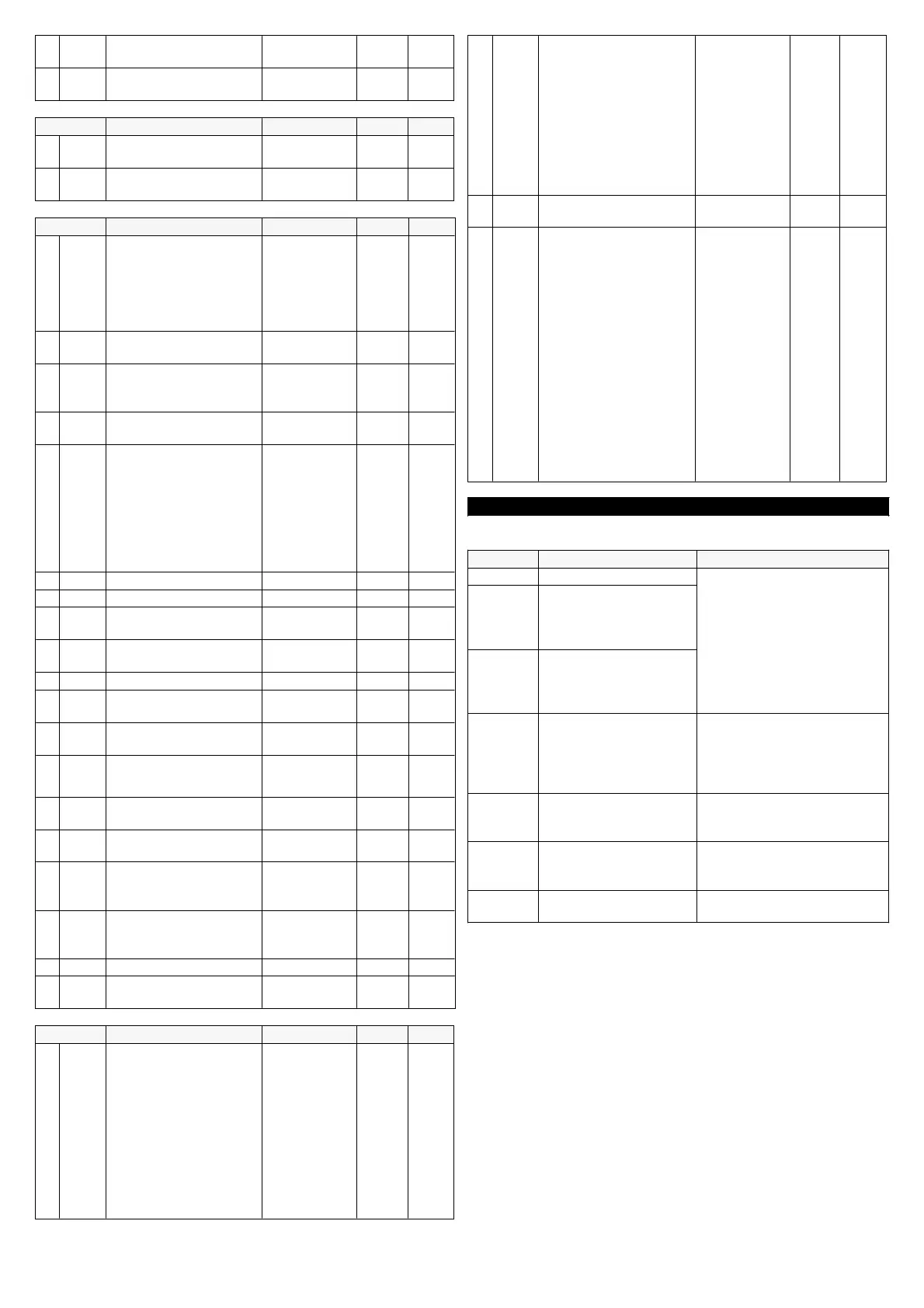

6 - PROBLEMS, MAINTENANCE AND GUARANTEE

6.1 - ERROR SIGNALLING

Push key “P”Possible anomaly of

the EEPROM memory

ErEP

Check the working of probe

and actuator and swap the

instrument to (rEG) control

Loop control

interrupted

(Loop break alarm)

LbA

Check the functioning of

probe and actuator and try

to repeat the auto-tuning.

Auto-tuning not

finished within 12

hours

noAt

Push key “P” in order to

make the error message

disappear. Once the error

has been found, try to

repeat the auto-tuning.

Auto-tuning not

possible because the

process value is too

higher or too lower

E

t

The measured

variable is over the

probe’s limits

(over-range)

oooo

The measured

variable is under the

probe’s limits

(under-range)

uuuu

Verify the correct

connection between probe

and instrument and then

verify the correct

functioning of the probe

Probe interrupted

- - - -

ction ReasonErro

In error conditions, the instrument provides an output power as

programmed on par. “OPE” and activates the desired alarms, if the

relative parameters “ALni” have been programmed = yES.

6.2 - CLEANING

We recommend cleaning of the instrument with a slightly wet cloth

using water and not abrasive cleaners or solvents which may

damage the instrument.

6.3 - GUARANTEE AND REPAIRS

The instrument is under warranty against manufacturing flaws or

faulty material, that are found within 12 months from delivery date.

The guarantee is limited to repairs or to the replacement of the

instrument. The eventual opening of the housing, the violation of

the instrument or the improper use and installation of the product

will bring about the immediate withdrawal of the warranty’s effects.

In the event of a faulty instrument, either within the period of

warranty, or further to its expiry, please contact our sales

TECNOLOGIC spa - TLK 48 - OPERATING INSTRUCTIONS - Vr. 03 - ISTR 06481 - PAG. 11

Loading...

Loading...