Do you have a question about the Tecumseh SPECTRA 37 and is the answer not in the manual?

General checks before starting engine repair procedures.

Procedure for starting engine using the recoil starter with choke.

Procedure for starting engine using the recoil starter with primer.

Systematic check for engine faults.

Checking engine compression for potential issues.

Troubleshooting engine ignition system faults.

Diagnosing and resolving fuel system issues.

Identifying faults originating from machine equipment.

Disassembly and assembly of recoil starter.

Details of side mounted horizontal engagement starter.

Disassembly and assembly of vertical engagement starter.

Procedure for stylized recoil starter disassembly.

Procedure for integral recoil starter disassembly.

Disassembly/reassembly for plastic wedge starter.

Battery checks and maintenance instructions.

Alternator function, air gap setting and testing.

Troubleshooting guide for starter motor issues.

Procedures for setting ignition timing.

Operation and air gap settings for CDI ignition.

Spark plug inspection, replacement and gap setting.

Maintenance for polyurethane foam air cleaner element.

Disassembly and maintenance of intake muffler.

Service for snorkel type pre-cleaner assembly.

Maintenance for Clean-Asp-Air filter systems.

Servicing procedures for oil bath air filter.

Maintenance instructions for Flymo turbo air filter.

Service for dual polyurethane filter with snorkel.

Maintenance for dual dry type paper element air cleaner.

Procedure for air cleaner with blower housing intake.

Check procedure and foam replacement for inverted flux type.

Replacement procedure for conical air cleaner cartridge.

Maintenance for paper air cleaner with blower intake.

Overview of diaphragm and float carburettor types.

Adjustment procedures for diaphragm carburettors.

Adjustment procedures for float style carburettors.

Description and adjustment of pneumatic governors.

Speed adjustment for AV and MV model governors.

Description of centrifugal governors for 4-stroke engines.

Description and adjustment of governor linkage.

Governor linkage adjustments for specific engine models.

Governor linkage for vertical crankshaft engines.

New governor lever and clamp specifications.

Governor plate adjustments for primer carburettors.

Introduction to uniblock engine components.

Inspection and replacement of reed plate.

General information on Mono Block MV100S engines.

Correct procedure for flywheel removal.

Steps for disassembling the engine block.

Procedure for connecting rod and piston assembly.

Crankshaft and ball bearing removal/refitting.

Instructions for reassembling the shroud base.

Details on alternative engine versions.

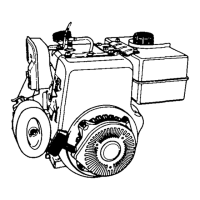

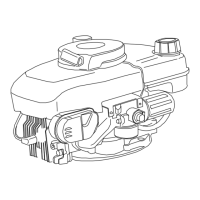

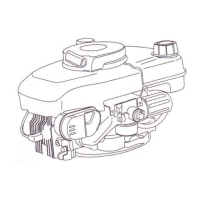

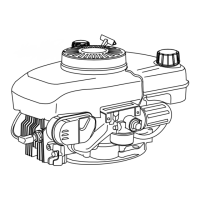

General construction overview of 4-stroke engines.

Procedure for checking engine compression.

Inspection, lapping, and servicing of valves and seats.

Steps for cylinder, piston, and rings disassembly.

Removal procedures for PTO ball bearing engines.

Internal engine component wear inspection.

Types and assembly of connecting rods.

Piston ring and pin inspection and installation.

Camshaft inspection and compression release system.

Lubrication systems for vertical and horizontal engines.

Standard mechanical governor components and service.

Crankcase breather operation and maintenance.

Maintenance for top mounted breather systems.

Procedure for oil seal replacement.

General reassembly sequence and oil seal fitting.

Cylinder and bearing installation procedures.

Identification and fitting of oversized pistons.

Piston and ring fitting and inspection.

Piston and connecting rod assembly procedures.

Camshaft, oil pump and cover reassembly steps.

Introduction to OHV engine valve train service.

Service procedures for OHV engine valve train.

Detailed steps for valve train disassembly and reassembly.

Procedure for setting valve lash on OVRM engine.

Cleaning, grinding, and servicing valve seats.

Troubleshooting guide for machine equipment issues.

Troubleshooting fuel and power supply unit issues.

Troubleshooting engine ignition system problems.

Troubleshooting electric starter unit issues.

Troubleshooting monoblock engine unit issues.

Loading...

Loading...