Preinstallation (Continued)

c. Blown fuses.

d. High amperage draw (excess

current) resulting in tripping the

overload protector.

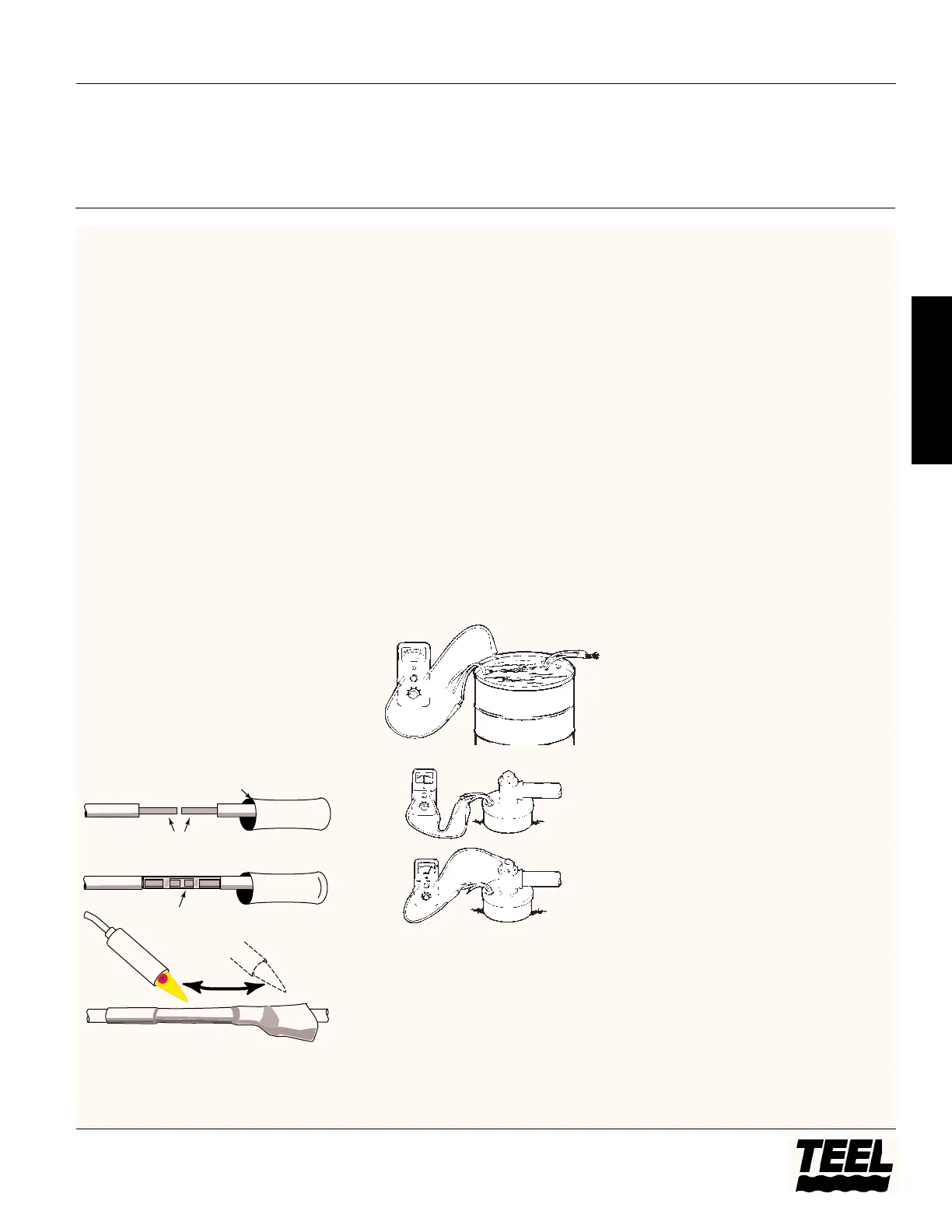

HEAT SHRINK SPLICING

FOR #8 WIRE CABLE

(Splice to #10 or smaller wire only)

(See Figure 2)

NOTE: When splicing to larger wires,

purchase splice kit to fit and follow

splice manufacturer’s instructions.

1. Remove 3/8” insulation from end of

motor pigtail leads and from drop

cable leads.

2. Place heat shrink tubing over

motor pigtail leads.

3. Insert leads into butt connector and

crimp with crimping tool. Pull leads

to check connection.

4. Center tubing over butt connector

and apply heat with a propane

torch (a match or lighter will not

supply enough heat).

NOTE: Keep torch moving; too much

concentrated heat in one place will

ruin tubing and may damage wires.

5. When tubing begins to shrink,

increase concentration of heat at

center of tube. As center of tube

collapses on wire, work heat out to

each end until entire tube is

collapsed tight around wire.

6. When splicing is complete, check

pump for continuous wiring

connections by running it in a

barrel of water. Insulation check

with ohm meter should be made at

this time. SEE INSULATION AND

CONTINUITY TEST.

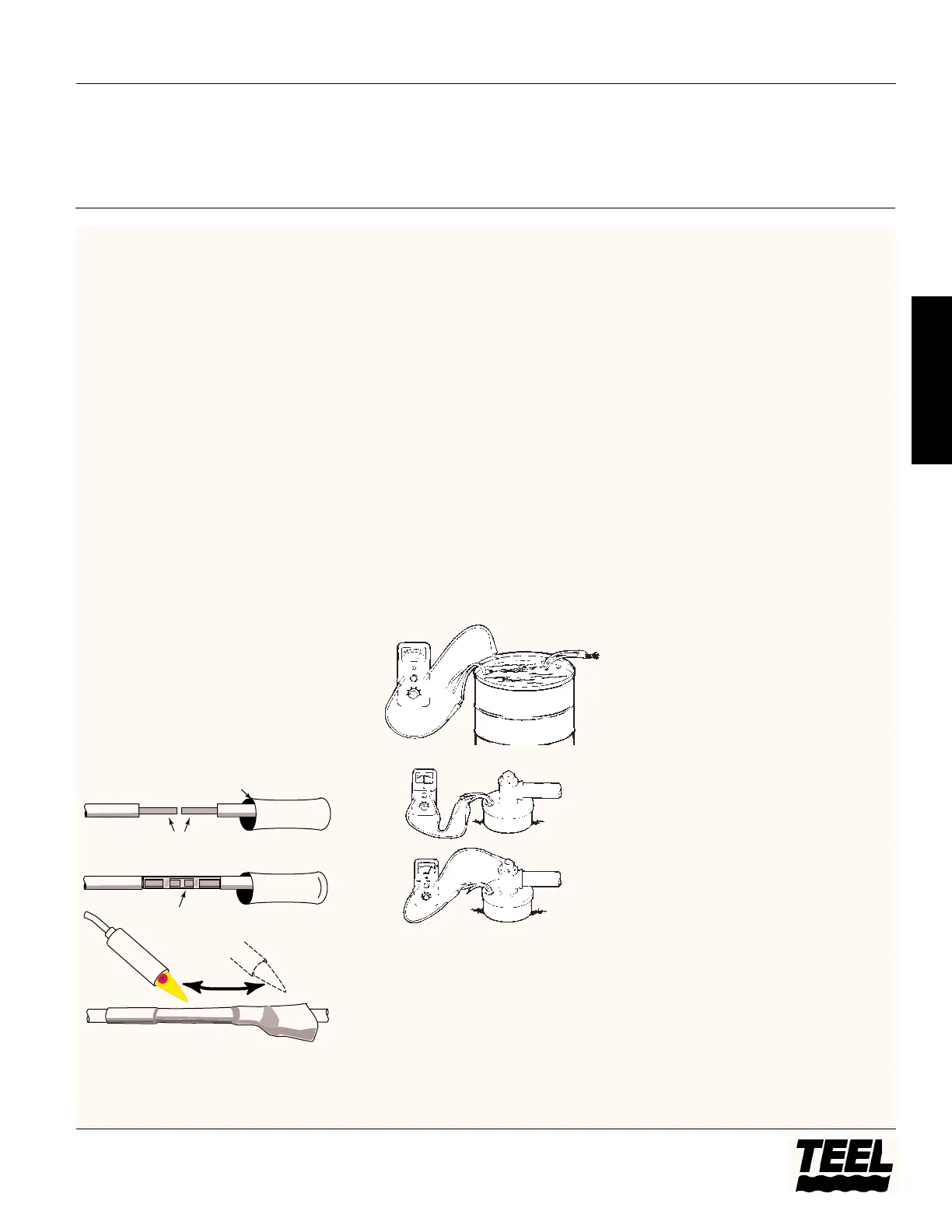

INSULATION AND CONTINUITY TEST

Do this test after splicing is complete

and pump is being test run in a tank of

water. Repeat test after installation in

well but before final electrical hookup

is made to control box or pressure

switch (See Figures 3 and 4).

1. Zero the ohmmeter by clipping the

leads together and adjusting the

zero ohm knob until the needle

indicates zero. Zero the ohmmeter

before each use or every time

selector switch is changed.

2. Clip one ohmmeter lead to bare

cable end.

3. Clip the other lead to edge of steel

tank in which pump and cable are

submerged. If pump is already in

the well, clip lead to metal

discharge pipe, metal well casing,

or motor ground lead.

4. A reading of 20,000 ohms or less

indicates a breakdown in the

insulation; in this case pull the

pump. If reading is between 20,000

and 500,000 ohms, cable or splice is

damaged; lift pump and slowly

raise cable from water (DO NOT try

to use the cable to take the weight

of the pump) with ohmmeter still

connected. When trouble spot

moves clear of the water,

ohmmeter needle will swing

toward ∞.

Installation

Install pump in a well which is sand

free, straight, and has sufficient flow

of water to supply the pump. Clear

well of sand and any other foreign

matter with a test pump before

installing your new submersible pump.

NOTE: Using the submersible pump to

clean the well will void the warranty.

When drilling a new well in an area

where sand is a problem, a sand screen

should be installed to protect the

pumping unit.

IMPORTANT: You will need the

following tools and fittings to properly

install your submersible pump.

• Pipe Wrenches

• Pipe vises or clamps

• Tripod

• Chain hoist or block and tackle

• Fittings

• Enough cable

• Tape or clamps to fasten cable

to discharge pipe

• Discharge pipe on convenient

lengths

• Well seal

• Fused disconnect switch

Models 4P847A thru 4P851A, 4P852 thru 4P865, 4RH01 thru 4RH06,

4RG76 thru 4RG84, 4RG94 thru 4RG97 and 4RG99

5

Teel Operating Instructions and Parts Manual

®

E

N

G

L

I

S

H

1. Keep the heat moving.

2. Don't overheat.

Loading...

Loading...