Installation (Continued)

PITLESS ADAPTER INSTALLATIONS

In this system, connection of piping in

the well to the system piping is by

means of the pitless adapter (See

Figure 9, Page 7).

Lower pump and pipe into well; pitless

adapter half on discharge pipe slides

into receiver attached to well casing

below frost line. Piping in well is much

the same as with a standard well seal; to

pipe system from well to house,

simply install the correct length of

plastic pipe and the appropriate fittings.

STANDARD WELL SEAL

INSTALLATIONS

In this system, the piping in the well

extends through the well seal and is

connected above ground to the system

piping by means of a tee or elbow (See

Figure 9, Page 7). This system provides

a sanitary, easily accessible installation.

IMPORTANT: A standard well seal

must be protected from freezing.

1. On a STANDARD PRESSURE TANK

INSTALLATION, assemble bleeder

orifice and pipe assembly as shown

in Figure 10A, Page 8.

On a PRECHARGED TANK

INSTALLATION, assemble system as

shown in Figure 10B, Page 8 (no

bleeder orifice required).

2. Attach unit used to plastic pipe

with two stainless steel hose

clamps. Tighten clamps securely.

NOTE: Be sure to assemble the tee to

the pipe above the well seal to prevent

dropping the pipe and pump down

the well as you lower it.

3. Assemble eyebolt (for safety rope),

lockwasher and nut in the tapping

on underside of well seal.

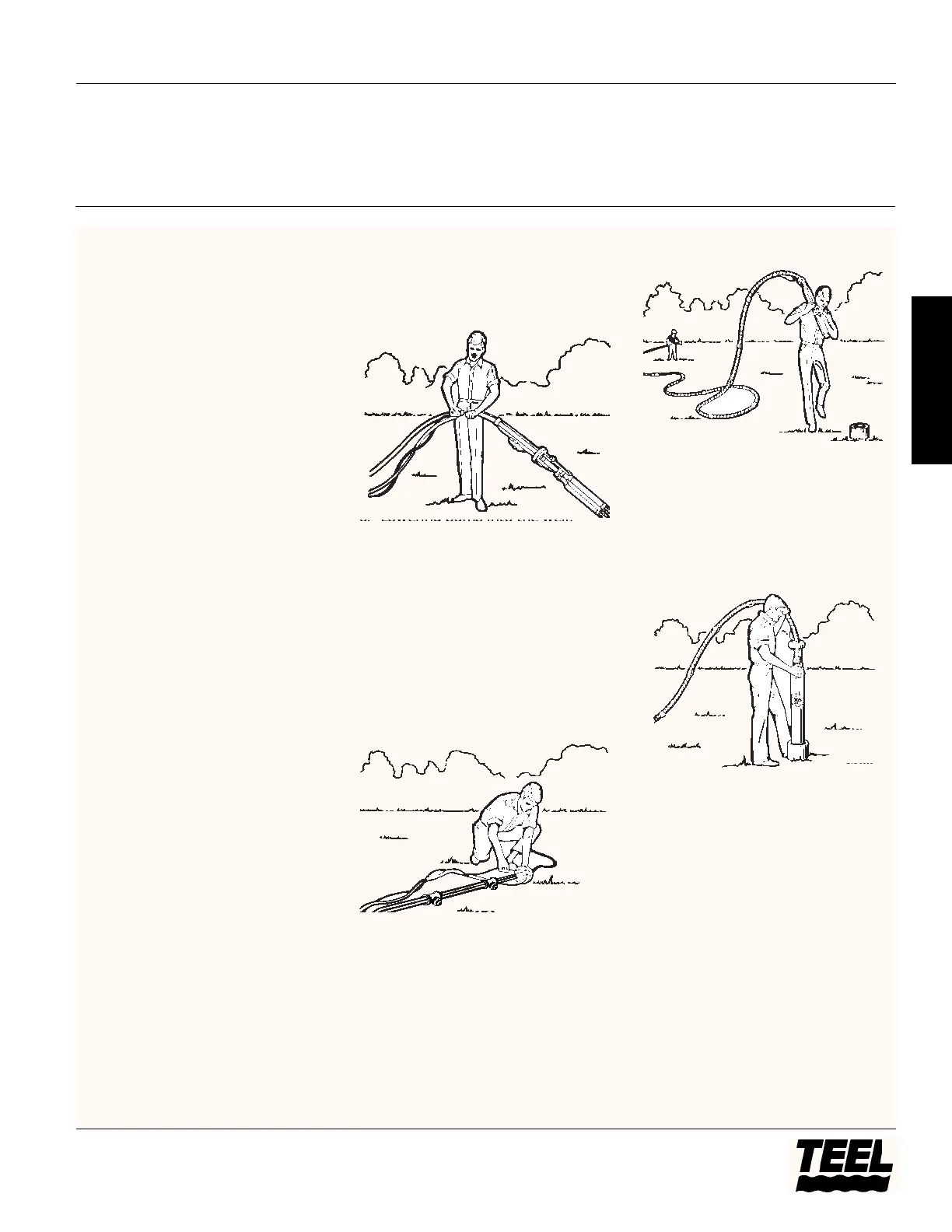

4. Tape electrical cable to the pipe

about every five feet (See Figure

11). Use only 1

1

⁄2 to 2 wraps of tape

to allow the cable to move slightly.

Tape spliced connections to the

pipe to eliminate rubbing against

well casing. Leave four to five feet

of slack at the upper end to allow

for plastic pipe stretch.

5. Tie safety rope to top of pump in

holes provided. Tape end of rope

to prevent unraveling. Tape safety

rope to pipe every 20 feet, making

sure there is no slack in rope. Tie

securely to eyebolt on bottom of

well seal (See Figure 12) and tape

end of rope. The complete

assembly is now ready to be

lowered into the well.

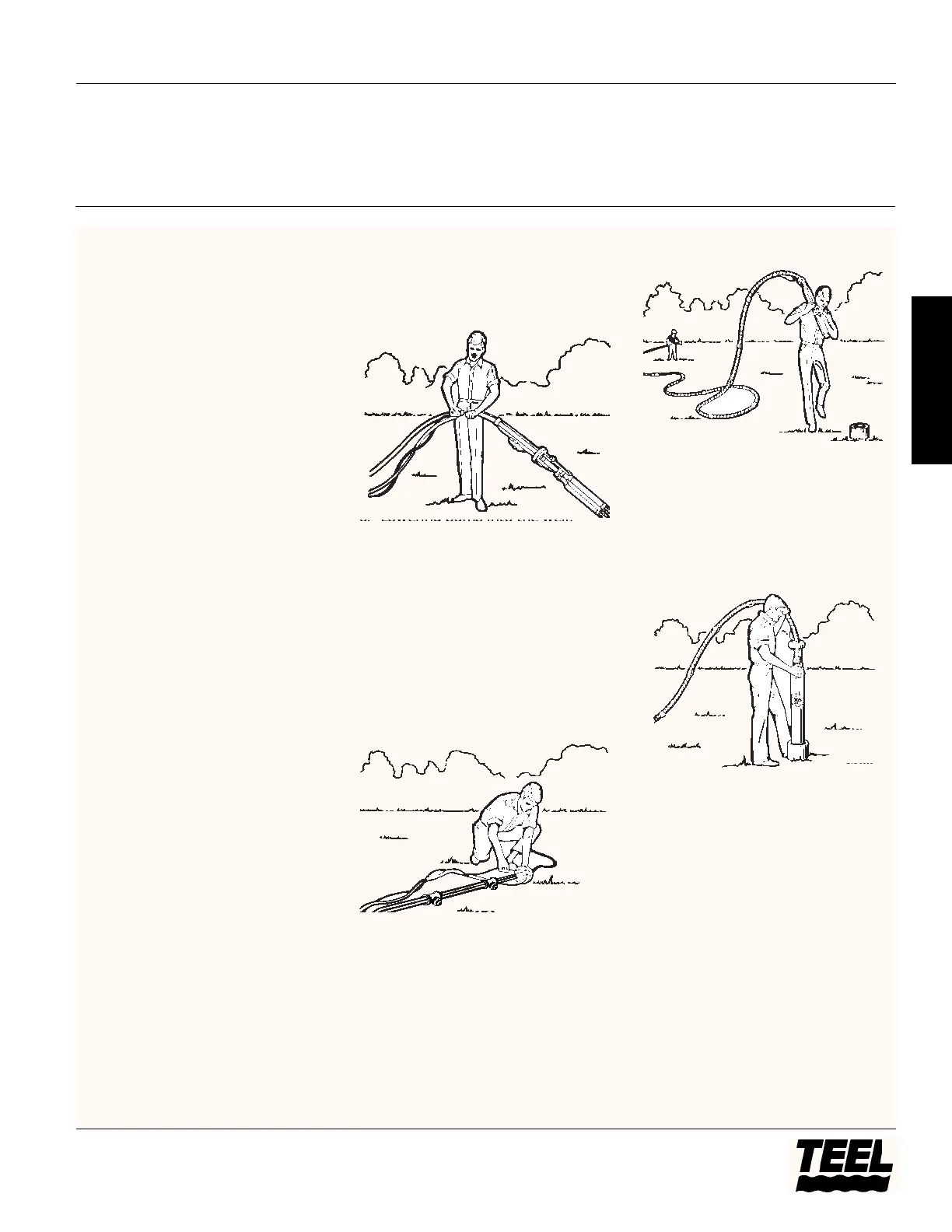

6. Lowering pump into the well:

IMPORTANT: Never support the

weight of pump and piping by the

electrical cable, as this weight will

break the cable connections. A helper

will be needed to handle the other

end of the assembly.

a. Lift the pump with the plastic

pipe and wire cable assembly

over your shoulder. BE SURE you

do not kink the plastic pipe (See

Figure 13).

b. Guide pump and piping into the

well. BE SURE you protect the

electrical cable when lowering

unit to avoid cuts, nicks, scrapes

or other damage by the edge of

the well casing (See Figure 14).

c. Have an assistant bring the

piping assembly toward you as

needed. Keep the pipe, cable,

and rope free of dirt, grass, or

other foreign matter.

d. Well seal installation: When

the entire assembly is in the

well, make sure seal is seated.

Tighten the four bolts in the

well seal evenly.

Pitless adapter installation:

Attach, to the top of the pitless

adapter, a length of pipe which

will reach to within 6”-8” of the

well head. Use this as a handle

(adding a second length with a

90° elbow on top and a 12”

length of pipe projecting to one

Models 4P847A thru 4P851A, 4P852 thru 4P865, 4RH01 thru 4RH06,

4RG76 thru 4RG84, 4RG94 thru 4RG97 and 4RG99

9

Teel Operating Instructions and Parts Manual

®

E

N

G

L

I

S

H

Figure 11

Figure 12

Figure 13

Loading...

Loading...