Performance Check Procedure—2213 Service

VERTICAL

Equipment Required (see Table 4-1):

Calibration Generator (Item 1)

50-J2 BNC Termination (Item 5)

Leveled Sine-Wave Generator (Item 2)

Dual-Input Coupler (Item 6)

50-ft BNC Cable (Item 4)

4

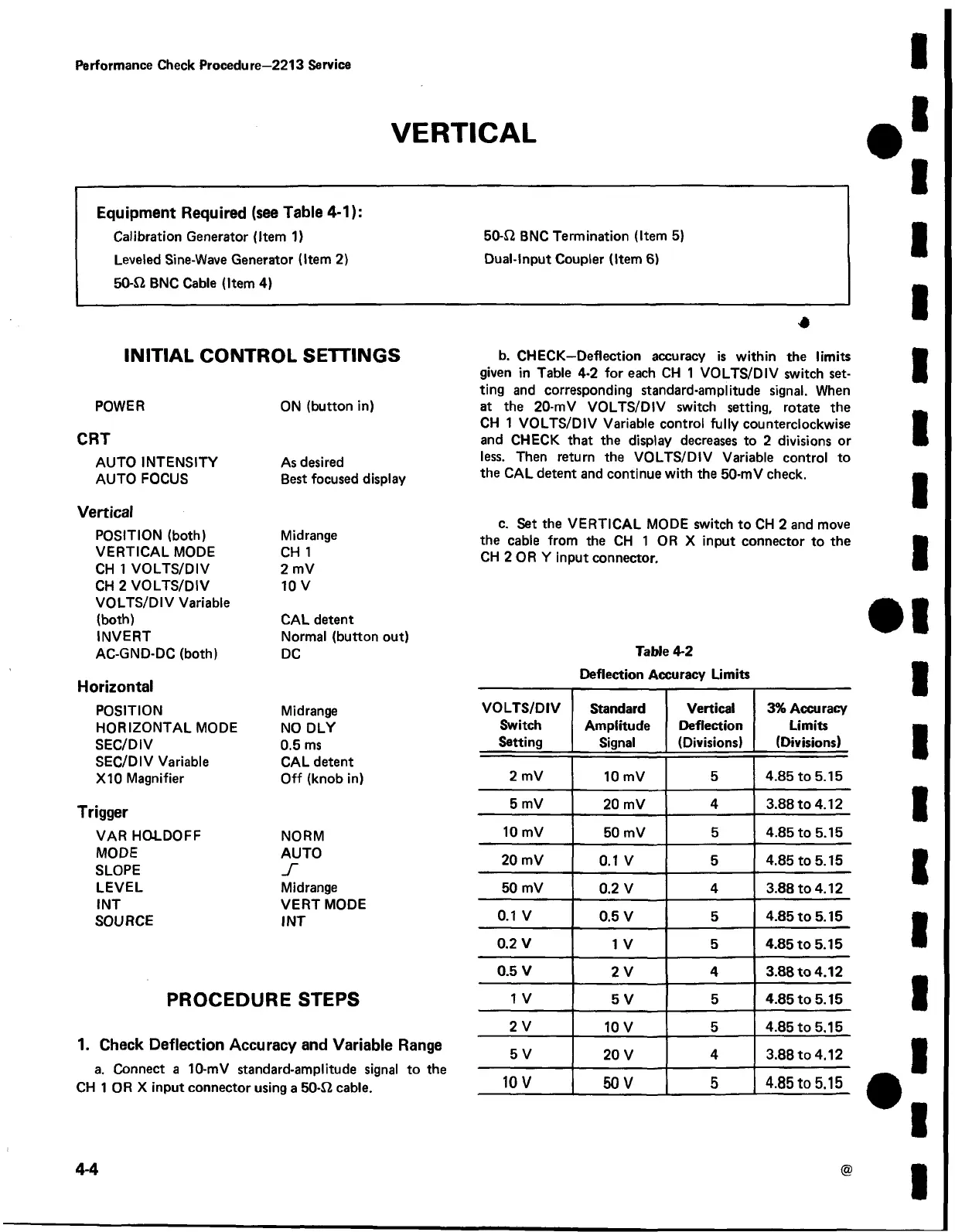

INITIAL CONTROL SETTINGS

POWER

CRT

AUTO INTENSITY

AUTO FOCUS

Vertical

POSITION (both)

VERTICAL MODE

CH 1 VOLTS/DIV

CH 2 VOLTS/DIV

VOLTS/DIV Variable

(both)

INVERT

AC-GND-DC (both)

Horizontal

POSITION

HORIZONTAL MODE

SEC/DIV

SEC/DIV Variable

X10 Magnifier

Trigger

VAR H04.DOFF

MODE

SLOPE

LEVEL

I NT

SOURCE

ON (button in)

As desired

Best focused display

Midrange

CH 1

2 mV

10 V

CAL detent

Normal (button out)

DC

Midrange

NO DLY

0.5 ms

CAL detent

Off (knob in)

NORM

AUTO

J~

Midrange

VERT MODE

I NT

PROCEDURE STEPS

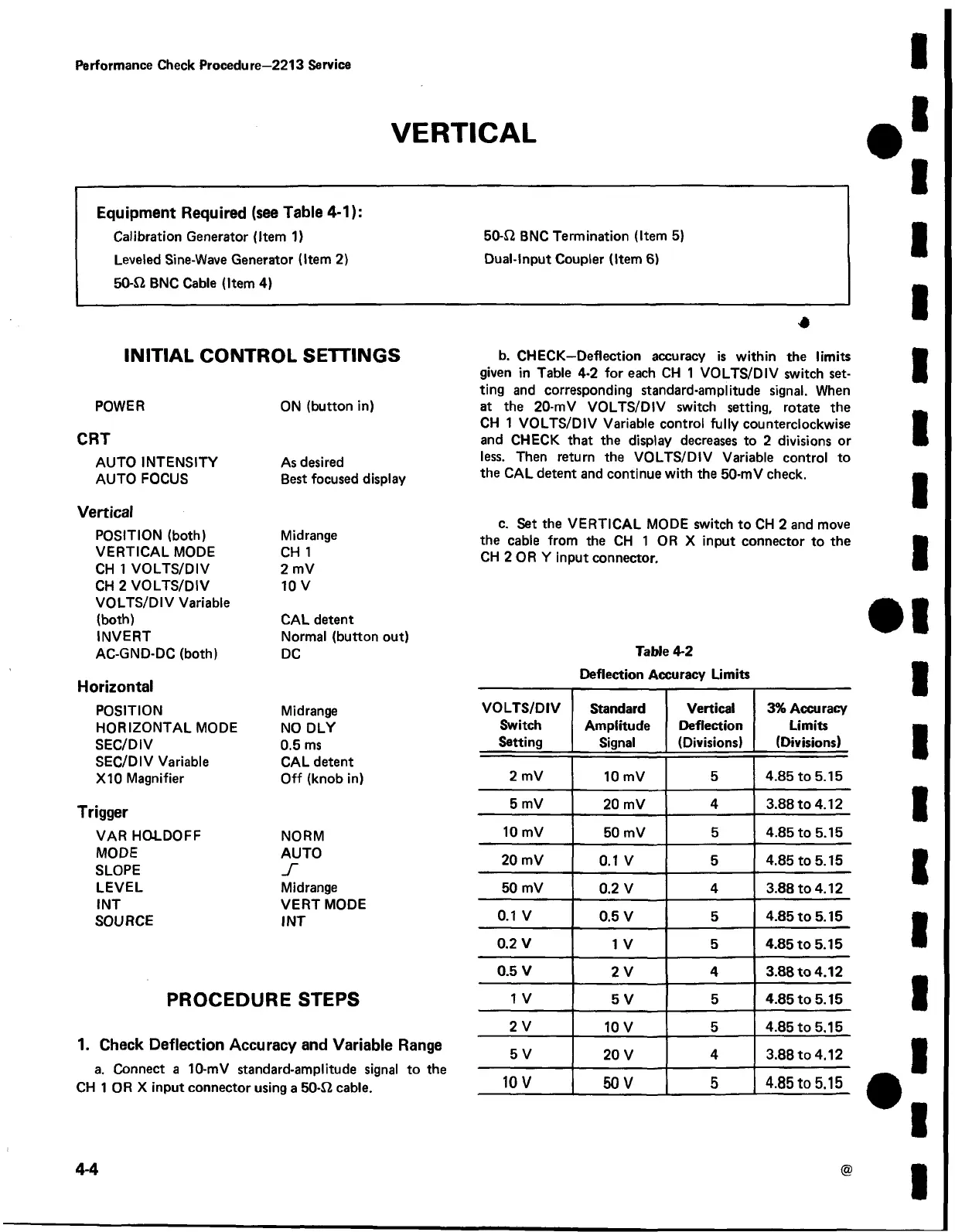

1. Check Deflection Accuracy and Variable Range

a. Connect a 10-mV standard-amplitude signal to the

CH 1 OR X input connector using a 50-J2 cable.

b. CHECK—Deflection accuracy is within the limits

given in Table 4-2 for each CH 1 VOLTS/DIV switch set

ting and corresponding standard-amplitude signal. When

at the 20-mV VOLTS/DIV switch setting, rotate the

CH 1 VOLTS/DIV Variable control fully counterclockwise

and CHECK that the display decreases to 2 divisions or

less. Then return the VOLTS/DIV Variable control to

the CAL detent and continue with the 50-mV check.

c. Set the VERTICAL MODE switch to CH 2 and move

the cable from the CH 1 OR X input connector to the

CH 2 OR Y input connector.

Table 4-2

Deflection Accuracy Limits

VOLTS/DIV

Switch

Setting

Standard

Amplitude

Signal

Vertical

Deflection

(Divisions)

3% Accuracy

Limits

(Divisions)

2 mV

10 mV

5

4.85 to 5.15

5 mV

20 mV

4

3.88 to 4.12

10 mV

50 mV

5 4.85 to 5.15

20 mV

0.1 V

5 4.85 to 5.15

50 mV

0.2 V

4

3.88 to 4.12

0.1 V

0.5 V 5 4.85 to 5.15

0.2 V

1 V

5

4.85 to 5.15

0.5 V

2 V 4 3.88 to 4.12

1 V

5 V

5 4.85 to 5.15

2 V

10 V

5 4.85 to 5.15

5 V

20 V

4

3.88 to 4.12

10 V

50 V 5

4.85 to 5.15

4-4

Loading...

Loading...