INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)MAC

26 440 01 4201 01

Specifications subject to change without notice.

Table 8 Maximum Capacity of Pipe

NOMINAL

IRON PIPE

SIZE

IN. (MM)

INTERNAL

DIA.

IN. (MM)

LENGTH OF PIPE − FT (M)

10

(3.0)

20

(6.0)

30

(9.1)

40

(12.1)

50

(15.2

)

1/2 (13)

0.622

(158)

175 120 97 82 73

3/4 (19)

0.824

(20.9)

360 250 200 170 151

1 ( 25)

1.049

(26.6)

680 465 375 320 285

1‐1/4 (32)

1.380

(35.0)

140

0

950 770 660 580

1‐1/2 (39)

1.610

(40.9)

210

0

146

0

1180 990 900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14-In. W.C.) or less and

a pressure drop of 0.5-In. W.C. (based on a 0.60 specific gravity gas). Ref: Table 8

above, and 6.2 of NFPA54/ANSI Z223.1-2009.

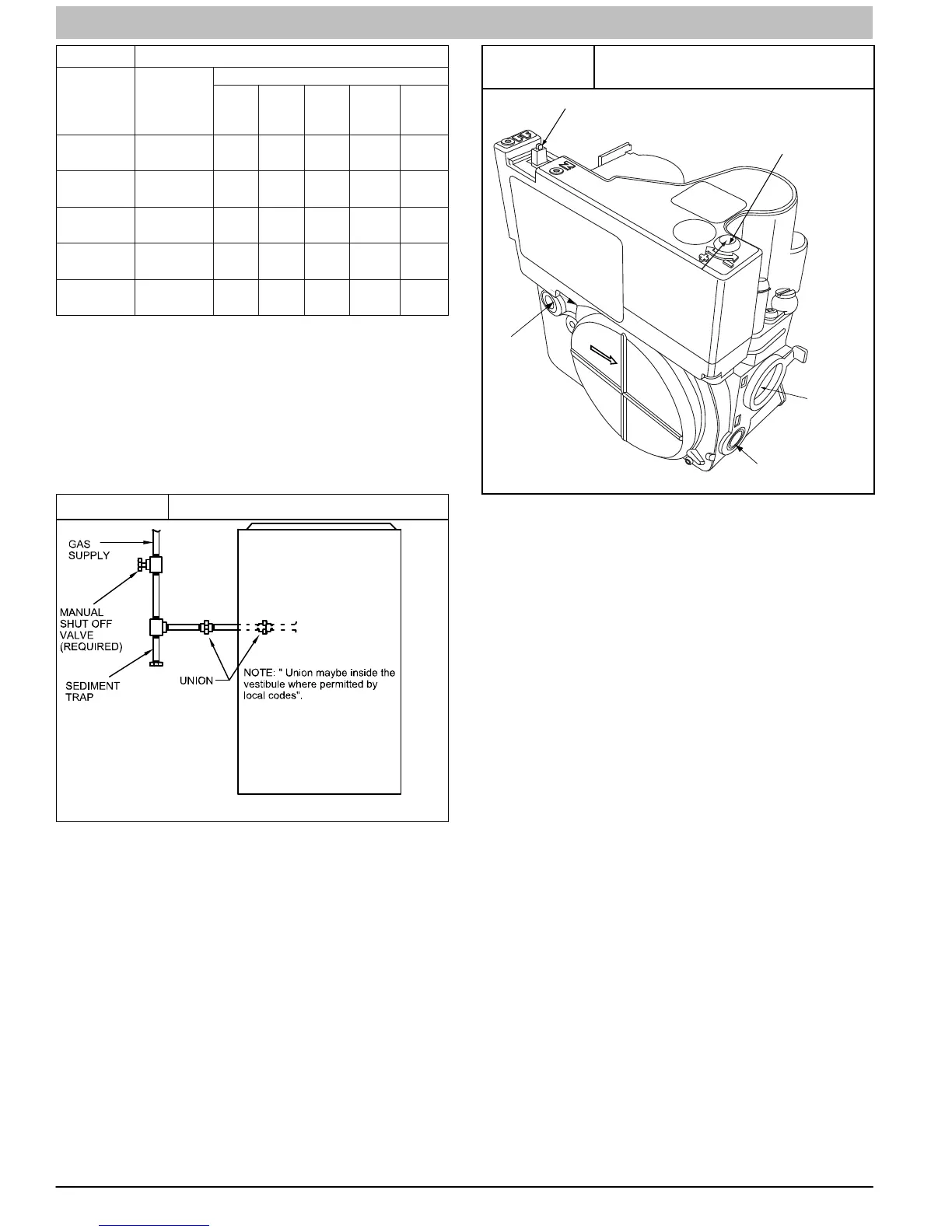

An accessible manual equipment shutoff valve MUST be

installed external to furnace casing and within 6 ft. (1.8 M) of

furnace.

Install a sediment trap in riser leading to furnace as shown in

Figure 31. Connect a capped nipple into lower end of tee.

Capped nipple should extend below level of furnace gas

controls. Place a ground joint union between furnace gas

control valve and exterior manual equipment gas shutoff valve.

Figure 31 Typical Gas Pipe Arrangement

L10F030

A 1/8−in. (3 mm) NPT plugged tapping, accessible for test

gauge connection, MUST be installed immediately upstream of

gas supply connection to furnace and downstream of manual

equipment shutoff valve.

Piping should be pressure and leak tested in accordance with

the current addition of the NFGC in the United States, local,

and national plumbing and gas codes before the furnace has

been connected. Refer to current edition of NSCNGPIC in

Canada. After all connections have been made, purge lines

and check for leakage at furnace prior to operating furnace.

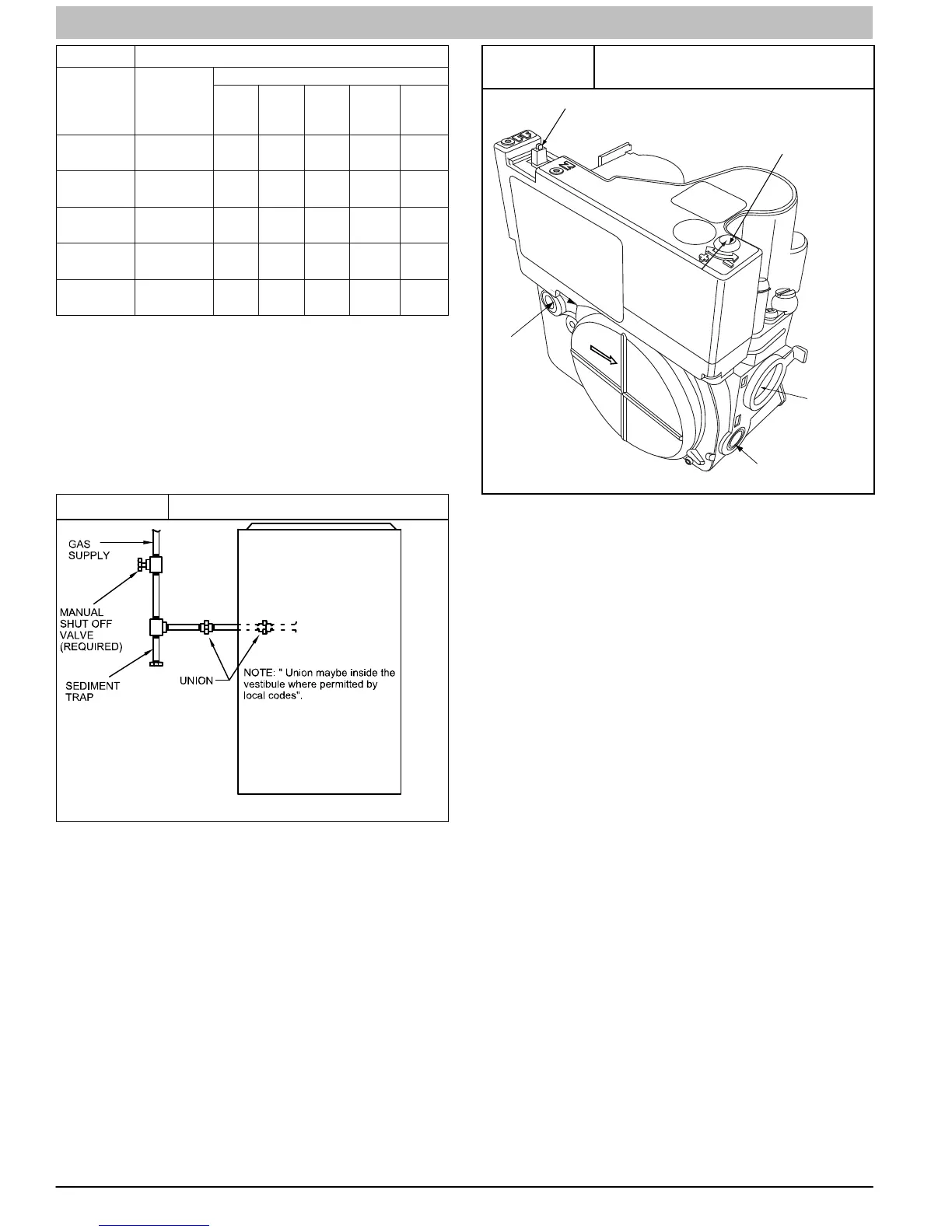

NOTE: The furnace gas control valve inlet pressure tap

connection is suitable to use as test gauge connection

providing test pressure DOES NOT exceed maximum 0.5 psig

(14−in. w.c.) stated on gas control valve. (See Figure 32)

Figure 32

Redundant Automatic Control

Valve (Modulating)

ON/OFF Switch

1/2” NPT Outlet

Manifold

Pressure Tap

Inlet

Pressure Tap

Min/Max Heat Adust

(Under Cap)

GAS FLOW

MODULATING

Turn screw 1 click per

second to adjust rate.

Clockwise to increase

rate, counter clockwise

to decrease rate.

A10496

If pressure exceeds 0.5 psig (14−in. w.c.), gas supply pipe must

be disconnected from furnace and capped before and during

supply pipe pressure test. If test pressure is equal to or less

than 0.5 psig (14−in. w.c.), turn off electric shutoff switch

located on furnace gas control valve and accessible manual

equipment shutoff valve before and during supply pipe

pressure test. After all connections have been made, purge

lines and check for leakage at furnace prior to operating

furnace.

The gas supply pressure shall be within the maximum and

minimum inlet supply pressures marked on the rating plate with

the furnace burners ON and OFF.

Some installations require gas entry on right side of furnace (as

viewed in upflow). (See Figure 33)

Gas Pipe Grommet

For direct vent (2-pipe) applications, the knockout for the gas

pipe must be sealed to prevent air leakage. Remove the

knockout, install the grommet in the knockout, then insert the

gas pipe. The grommet is included in the loose parts bag. (See

Figure 33)

Loading...

Loading...