INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)MAC

440 01 4201 01 31

Specifications subject to change without notice.

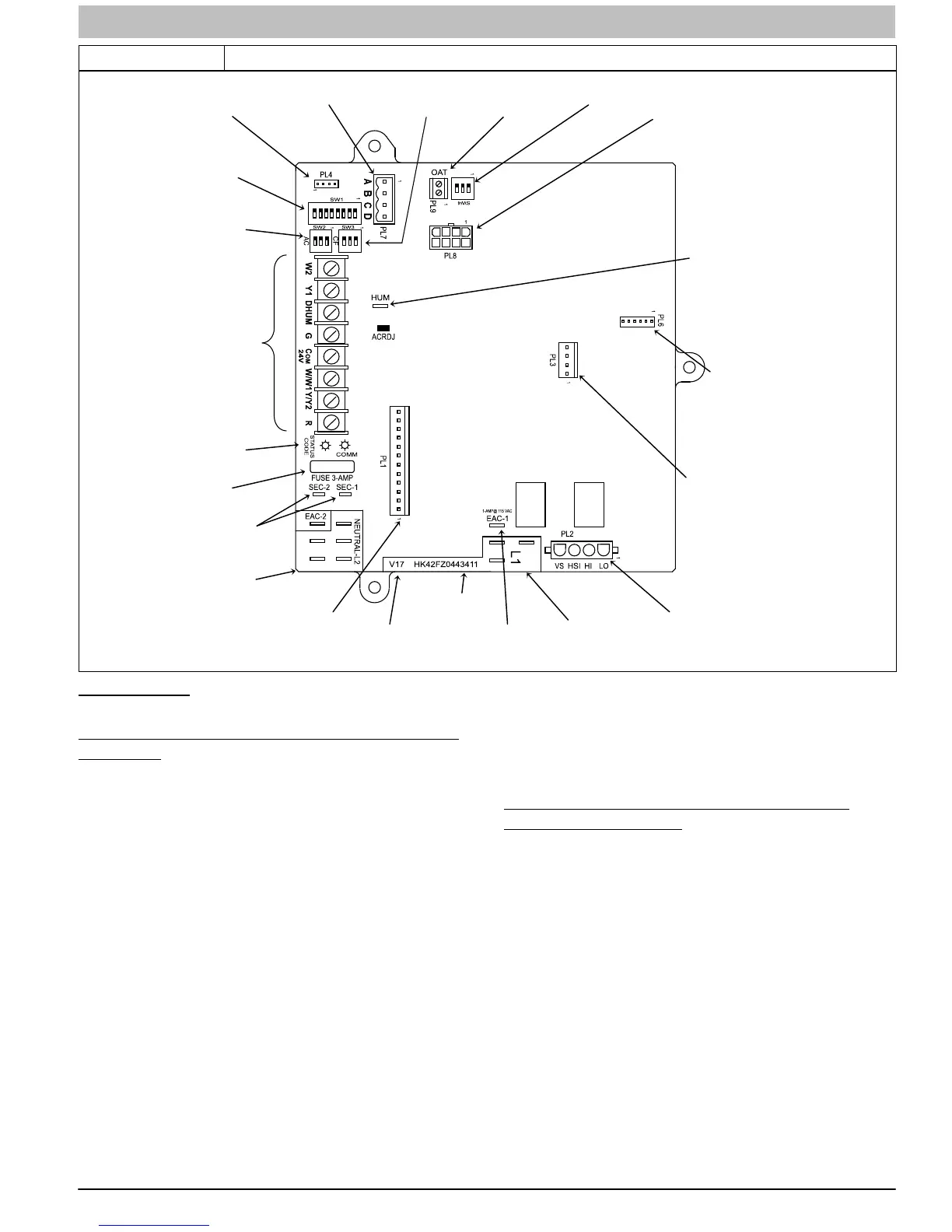

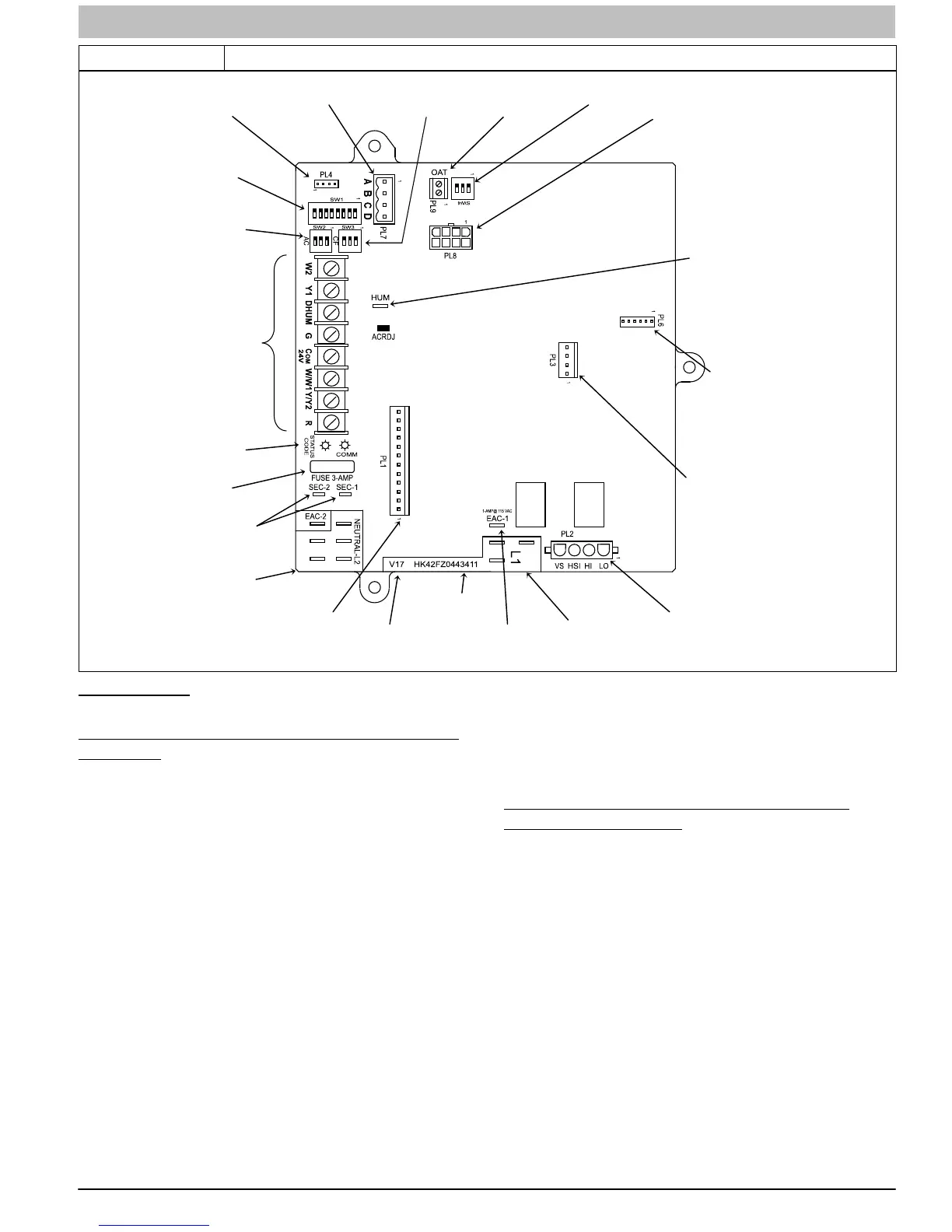

Figure 39 (CONT.) Variable Speed Furnace Control for ECM Blower Motor (Modulating)

TERMINALS

PL2 – HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

115-VAC (L2) NEUTRAL

CONNECTIONS

115-VAC (L1) LINE

VOLTAGE CONNECTIONS

EAC-1 TERMINAL

(115-VAC 1.0 AMP MAX.)

PL1 – LOW VOLTAGE MAIN

HARNESS CONNECTOR

HARNESS

CONNECTOR

TRANSFORMER 24-VAC

CONNECTIONS

STATUS AND COMM

LED LIGHTS

BLOWER OFF-

AIR CONDITIONING

(A/C) AIRFLOW

SETUP SWITCHES

CONTINUOUS FAN

(CF) AIRFLOW

SETUP SWITCHES

A

-

FLASH

UPGRADE

CONNECTOR

(FACTORY

ONLY)

PART NUMBER AND

DATE CODE WWYY

GAS VALVE

L11F061

VENTING

Furnace is set in place in the required orientation.

Special Venting Requirements for Installations

in Canada

Installation in Canada must conform to the requirements of

CAN/CSA B149 code. Vent systems must be composed of

pipe, fittings, cements, and primers listed to ULC S636. The

special vent fittings and accessory concentric vent termination

kits and accessory external drain trap have been certified to

ULC S636 for use with those Royal Pipe and IPEX PVC vent

components which have been certified to this standard. In

Canada, the primer and cement must be of the same

manufacturer as the vent system – GVS-65 Primer (Purple) for

Royal Pipe or IPEX System 636, PVC/CPVC Primer, Purple

Violet for Flue Gas Venting and GVS-65 PVC Solvent Cement

for Royal Pipe or IPEX System 636

(1)

t, PVC Cement for Flue

Gas Venting, rated Class IIA, 65 deg C. must be used with this

venting system - do not mix primers and cements from one

manufacturer with a vent system from a different manufacturer.

Follow the manufacturer’s instructions in the use of primer and

cement and never use primer or cement beyond its expiration

date.

The safe operation, as defined by ULC S636, of the vent

system is based on following these installation instructions, the

vent system manufacturer’s installation instructions, and proper

use of primer and cement. All fire stop and roof flashing used

with this system must be UL listed material. Acceptability under

Canadian standard CAN/CSA B149 is dependent upon full

compliance with all installation instructions. Under this

standard, it is recommended that the vent system be checked

once a year by qualified service personnel.

The authority having jurisdiction (gas inspection authority,

municipal building department, fire department, etc) should be

consulted before installation to determine the need to obtain a

permit.

*IPEX System 636™ is a trademark of IPEX Inc.

Consignes spéciales pour l’installation de

ventilation au Canada

L’installation faite au Canada doit se conformer aux exigences

du code CAN/CSA B149−2010. Ce systême de ventillation doit

se composer de tuyaux, raccords, ciments et apprêts

conformes au ULC S636. La tuyauterie de ventillation des gaz,

ses accessoires, le terminal concentrique mural ainsi que

l’ensemble du drain de condensat extérieur ont été certifiés

ULCS 636 pour l’application des composantes Royal Pipe,

IPEX PVC qui sont certifiées à ce standard. Au Canada,

l’apprêt et le ciment doivent être du même fabricant que le

système d’évacuation. L’apprêt GVS-65 (Purple) et le

ciment-solvant GVS-65 doivent être utilisé avec les Royal Pipe.

Système IPEX 636, apprêt PVC/CPVC, Purple pour

évacuation des gaz de combustion et système IPEX 636(1)t,

ciment PVC pour évacuation des gaz de combustion, coté

classe IIA, 65 deg C. doivent être utilisés avec le système

d’évacuation IPEX 636 – Ne pas combiner l ’apprêt et le ciment

d’un manufacturier avec un système d’évacuation d’un

manufacturier différent.

Loading...

Loading...