CF Series Portable Chiller : Air & Water-Cooled : 5 - 40 Tons

Page: 56

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

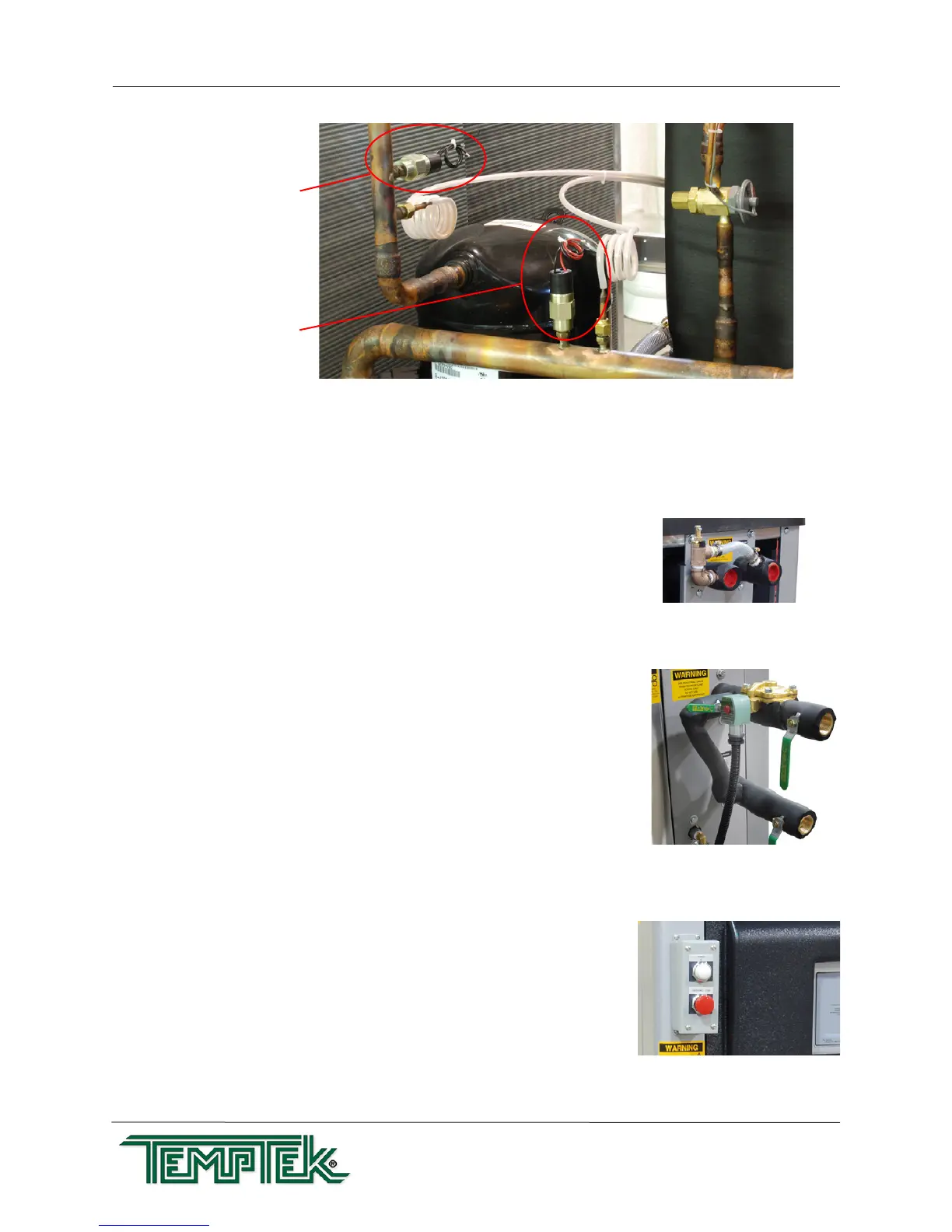

L. Service valves:Thesevalvesarelocatedthroughoutthesystem.Onlyaqualied

refrigeration service technician shall operate these valves.

6.3 UNIT OPTIONS

A. LOW FLOW BYPASS: If your process will experience lower

thandesignowratesorintermittentow,alowowbypass

valve will be required.

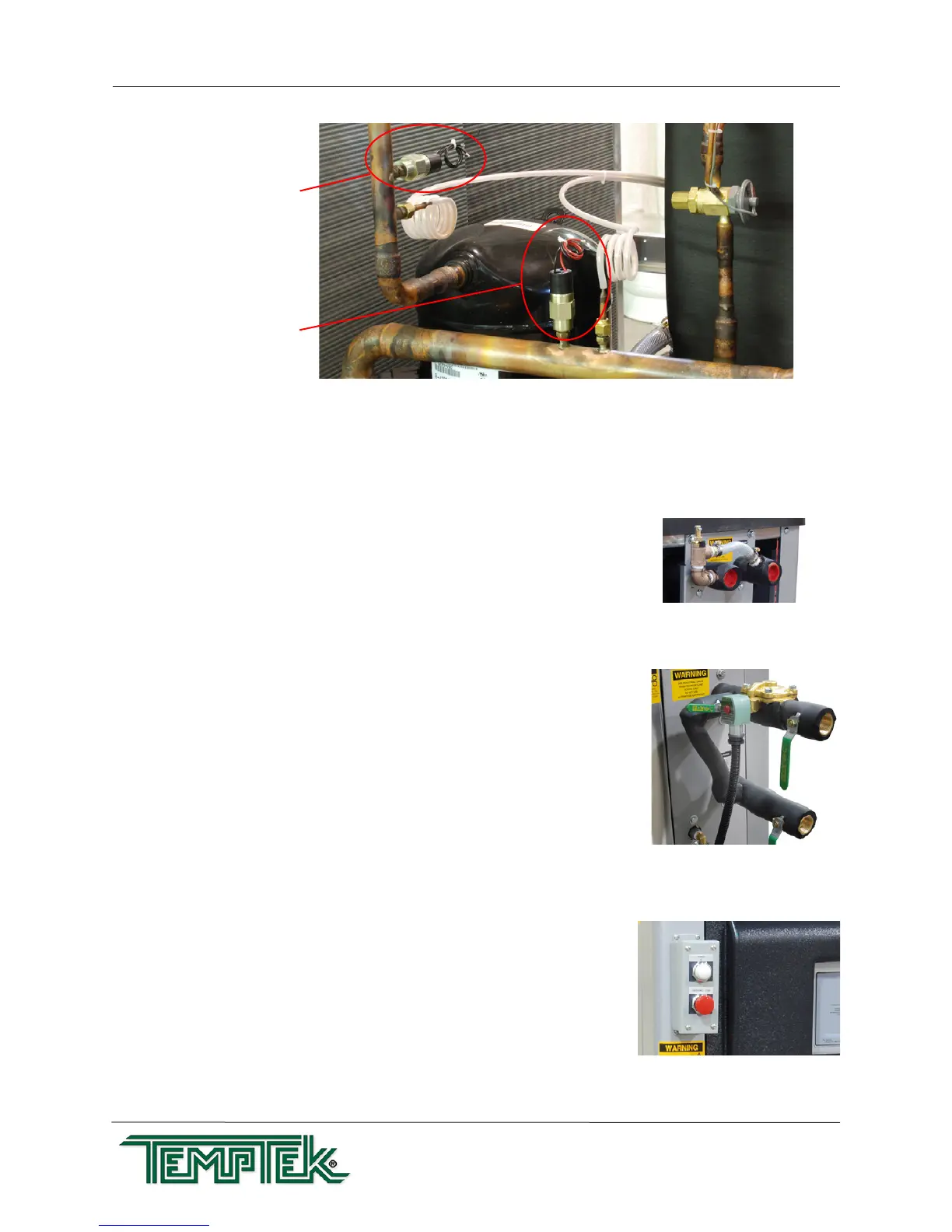

B. OVERHEAD PIPING KIT: Toavoidreservoiroverow

during shut down periods from overhead piping, Advantage

recommends the installation of an overhead piping kit. The

overhead piping kit consists of a full line size solenoid

valve in the “from process” line that is interlocked with the

pump and a check valve (single direction valve) in the “to

process” line.

C. PROCESS LINE SHUT OFF VALVES: These valves are

full size ball valves installed on the “to” and “from” process

lines at the exit of the chiller. These valves can be used to

adjusttheprocessowrateandtoshutofftheowrateto

isolate the chiller.

D. E-STOP BUTTON: The Emergency stop button is a

mushroom type button which will shut down all chiller

operations when engaged.

E. NON-FUSED OR FUSED DISCONNECT SWITCH: On

board disconnect switch provides a convenient location

for isolating all electric power to the chiller.

F. AUDIBLE AND OR VISUAL ALARM: Alarms indicate

out-of-spec operating conditions. There are two types of

alarms:

Typicalplacementofnon-adjustable“xed”pressureswitches.

Non-adjustable“xed”

low pressure switch

Non-adjustable“xed”

high pressure switch

Typical optional automatic low

owbypassvalve.

Emergency stop button. Shown with

Power On light.

Typical overhead piping kit. Shown

with optional process line shut off

valves. Process line shut off valves

are also shown in this photo.

Loading...

Loading...