3-2

Caution

Do not allow the pump to operate with a frequency beyond 60 Hz.

Doing so may overload the motor, causing it to burn out.

3.3 Precautions for installation

Warning

Before rotating the pump shaft by hand to check it, be sure to turn off the

main power. Sudden operation of the pump may cause an accident.

(1) Install the product in a well-ventilated place with minimum exposure to dust and moisture.

(Refer to 2.3 “Standard specifications”.) In particular, avoid installing the product in a place

where the liquid used is splashed on the motor section.

Warning

Do not install the product in a place exposed to high temperature and

moisture.

Failure to observe this may cause heating, ignition and electric leakage.

(2) Install the product in such a way that the motor can take in air.

(3) Select a flat place for the mounting surface and then install the product so as not to rattle.

(4) Select a place convenient for maintenance and inspection. Ensure maintenance clearances.

(5) The mounting surface should be strong enough to prevent vibration from being amplified when

the pump is running.

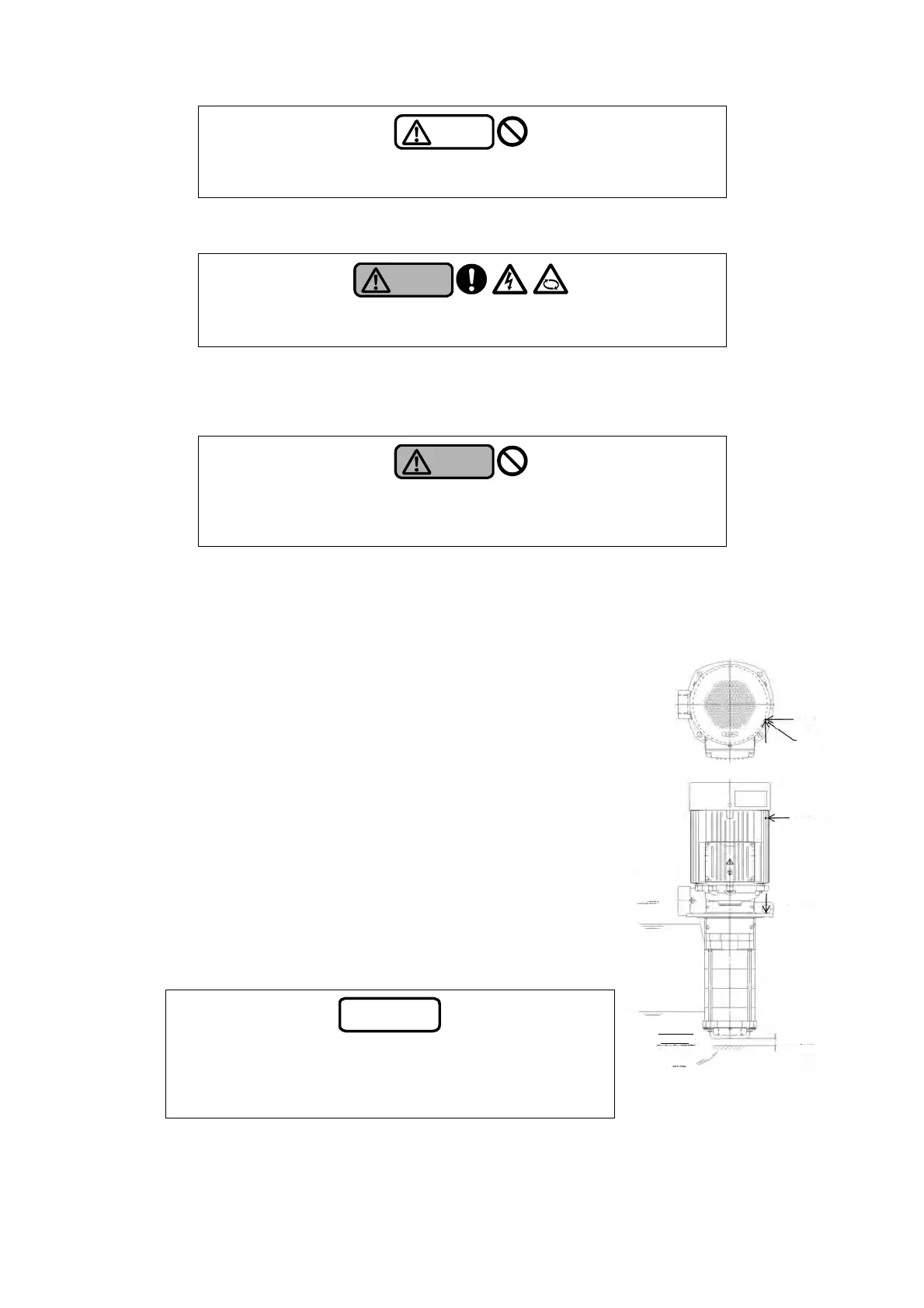

(Restrict the total amplitudes in X, Y and Z directions (see the

right figure) to 33μm at 50 Hz and 29μm at 60 Hz during pump

operation.)

(6) It is necessary to make a mounting hole larger than the outside

diameter of the pump section so as to put the pump section into

the tank (oil tank). See the dimensional outline drawing.

(7) Install the product so that the pump shaft becomes vertical.

(8) Use the product with the pump section immersed under the oil

level. The suction port should be at least 17 mm away from the

bottom surface of the tank (oil tank) to prevent the strainer from

getting clogged with cutting powder, dirt, etc. If it is conceivable

that cutting powder, dirt, etc. are deposited on the bottom of the

tank, ensure as large a distance as possible at the design

stage.

Note

The oil level in the tank (oil tank) should always be above the

lowest oil level.

Keep a distance of at least 17 mm from the pump suction plane

to the tank (oil tank).

(9) The product is coated, but if it is overcoated to another color for unavoidable reasons, lightly

roughen the product surface with sand paper and then coat it. The adhesion properties of the

coating film are improved. (Be sure to check that a paint to be used is applicable to

overcoating.)

X: Measurement

direction

Z: Measurement point

X, Y: Measurement

point

Y: Measurement

direction

Z: Measurement

direction

Min. 17 mm

Suction

Bottom of

the tank

Highest

liquid level

Lowest

liquid level

Discharge

Loading...

Loading...