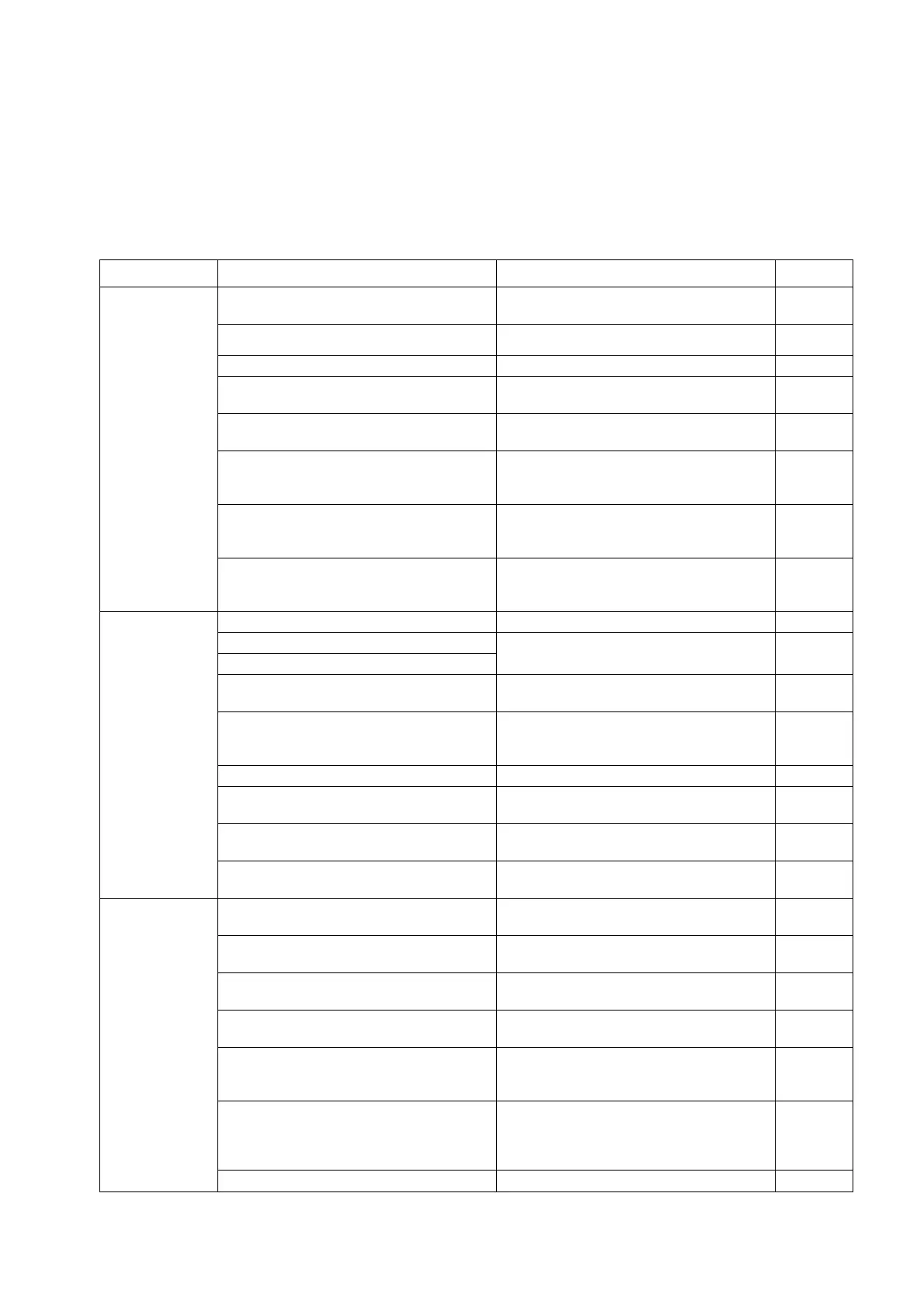

6-1

6. Troubleshooting

The following table lists causes of failures and their measures. In the event of a failure, however, you

should carefully investigate the problem and ask the vendor to carry out any measures that are considered

difficult.

Problem Cause (Reference page) Measures (Reference page) Operator *

Wiring is disconnected or broken.(3-4)

Check the wires and connections.

Repair or replace.

Vendor

The power fuse is blown. Replace it with an appropriate fuse. User

Tripping of the thermal relay Check the thermal relay. User

Poor connection or contact of power

wires(3-4)

Check the wires and connections. Vendor

The power voltage is too low.(2-2)

Check the power voltage.

Contact the power company.

User

The motor has failed. (e.g. wire breakage of

the stator winding)

Repair at vendor's shop.

Contact the vendor because disassembly

and inspection are required.

Vendor

Foreign matter is caught in the impeller.

Disassemble, clean, and repair.

Contact the vendor because disassembly

and inspection are required.

Vendor

The pump does

not start.

The bearing is rusty.(5-1)

Replace the bearing.(5-1)

Contact the vendor because disassembly

and inspection are required.

Vendor

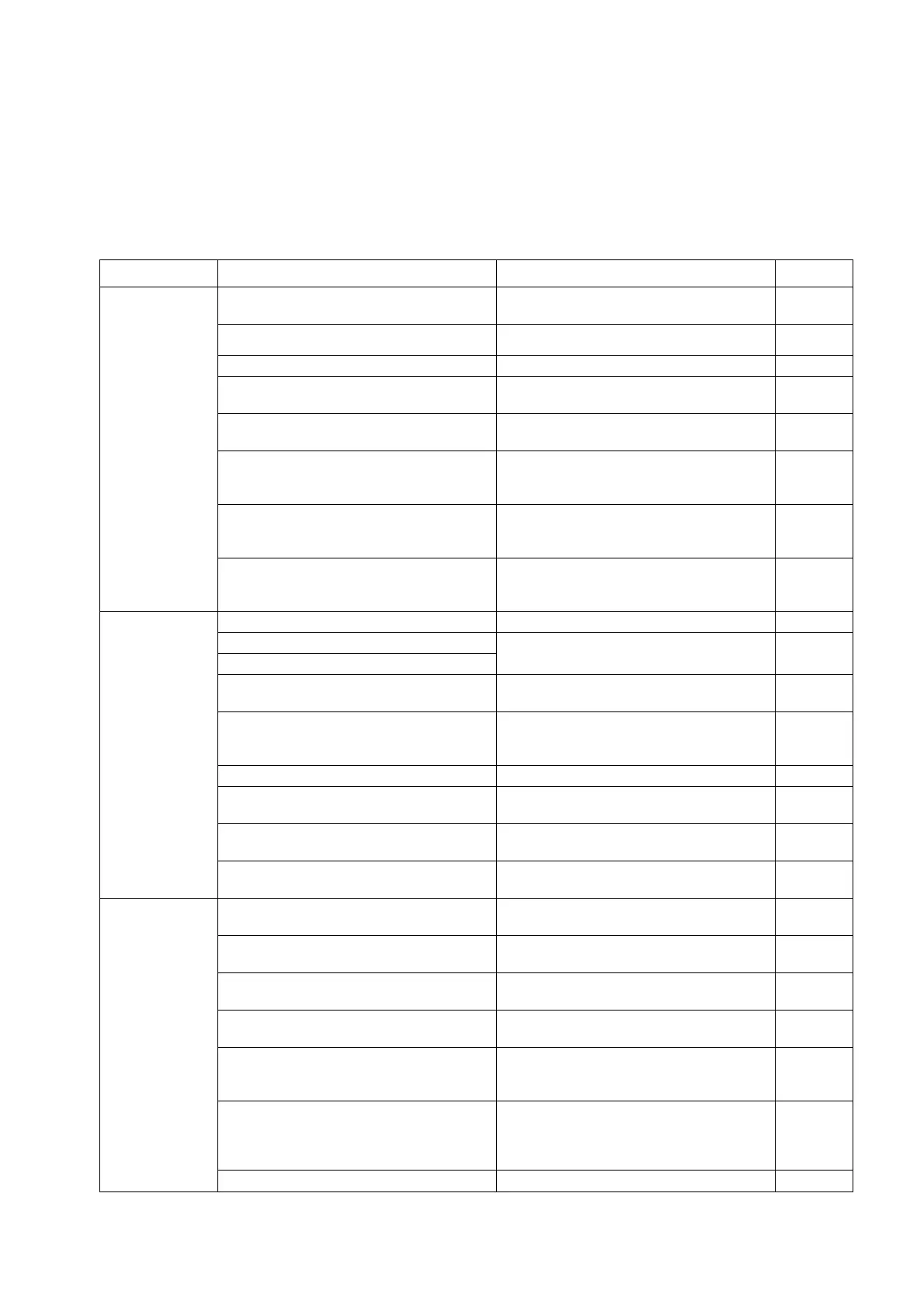

The rotating speed is too high. Check with the tachometer. User

The voltage is too high or too low.(2-2)

The voltage is unbalanced.

Check the power voltage.

Contact the power company.

User

The stator winding is broken, shorted, and

grounded.

Contact the vendor because disassembly

and inspection are required.

Vendor

The stator and rotor are in contact due to

wear of the bearing.(5-1)

Replace the bearing.(5-1)

Contact the vendor because disassembly

and inspection are required.

Vendor

Open-phase failure occurs. Check the wiring. User

The dynamic viscosity of the liquid used is

too high. (2-2)

Use a liquid with low dynamic viscosity. User

The discharge rate is high.

Throttle the sluice valve to meet the

specifications.

User

Overload and

overcurrent of the

motor

The rotating part is in contact with another

part.

Contact the vendor because disassembly

and inspection are required.

Vendor

Lots of air bubbles are contained in the

liquid used.

Avoid bubbling and the suction of air

bubbles.

User

The rotation direction is reverse.(4-2)

Correct the wiring so that the direction is

normal.(4-2)

User

The piping loss is high.

Check the piping diameter, route and

length.

User

The piping is clogged up with foreign

matter.

Remove the foreign matter, and check the

connections.

User

The impeller is worn.

Replace the impeller.

Contact the vendor because disassembly

and inspection are required.

Vendor

Foreign matter is accumulated on the

impeller and in the casing.

Remove the foreign matter, and check the

connections.

Contact the vendor because disassembly

and inspection are required.

Vendor

The pump starts,

but cannot

achieve the

specified

discharge rate

and the specified

head.

The rotating speed is low. Check with the tachometer. User

Loading...

Loading...