2-2

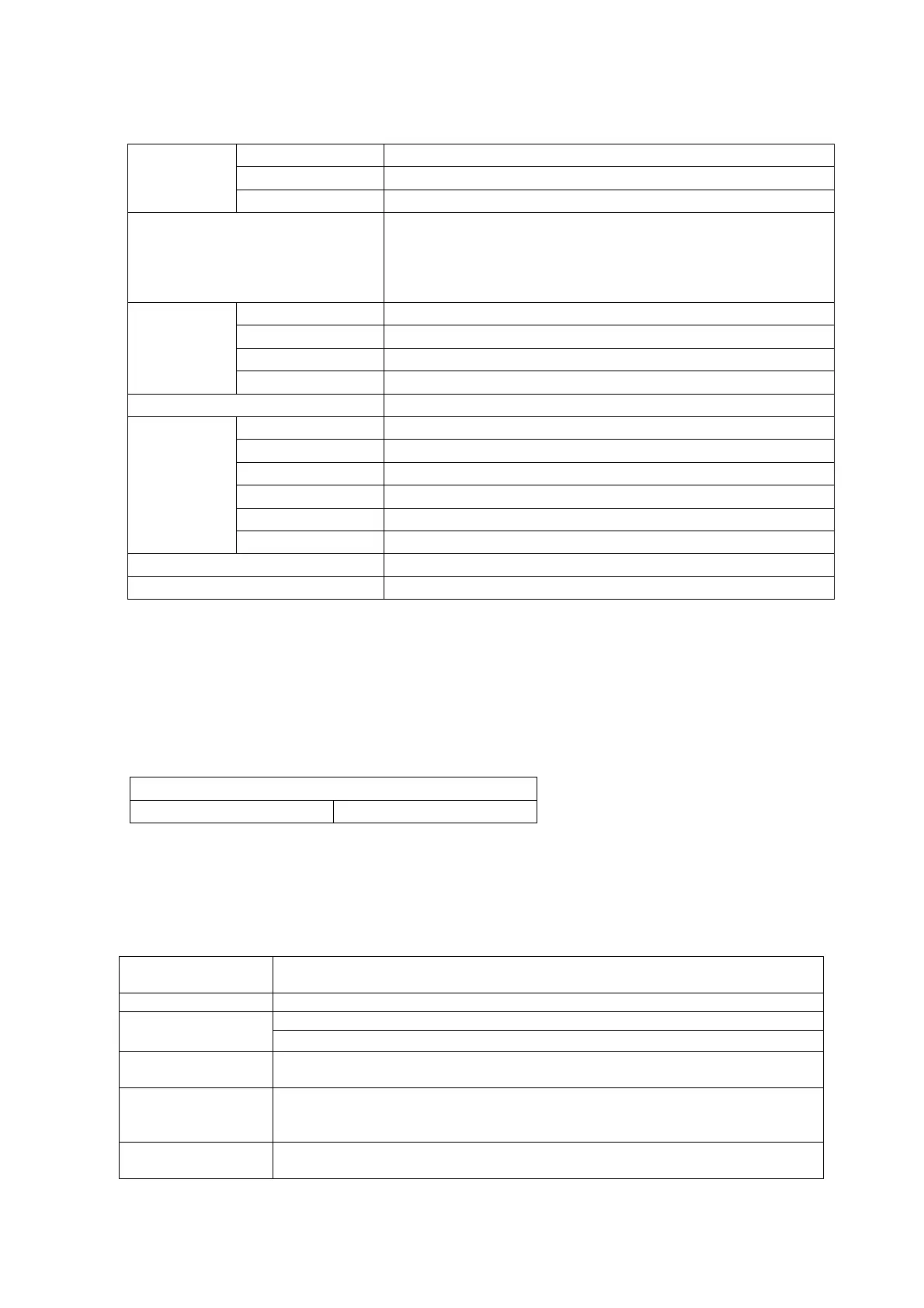

2.3 Standard specifications

Quality Grinding fluid, cutting fluid, etc. after primary treatment

Note1

Temperature -20 to 40°C (No freezing is allowed.)

Applicable

liquid

Dynamic viscosity See

Note2

.

Installation location

Indoors, Height above sea level: 1,000 m or less, Ambient

temperature: -20 to 40°C, Humidity: 85% or less (No

condensation is allowed.), Place not exposed to direct sunlight,

Place whose atmosphere contains no corrosive gas, explosive

gas or vapor

Pump leg FC200

Casing FC200

Impeller FC200

Material

Motor spindle S45C

Shaft sealing structure Non-seal (mechanical seal-free) structure

Type Totally-enclosed fan-cooled indoor type

IP protection IP54

Power

Note3

3-phase 50/60Hz 200/200-220V

Insulation class Class F

Number of poles 2P

Motor

Standard IEC60034-1

Noise[dB(A)] 77

Coating color Munsell N1

Note1 Notice that the liquid in question cannot be used with water and special liquids such as printing liquids

and acidic liquids. For other special liquids (ceramic etc.), contact Teral Inc.

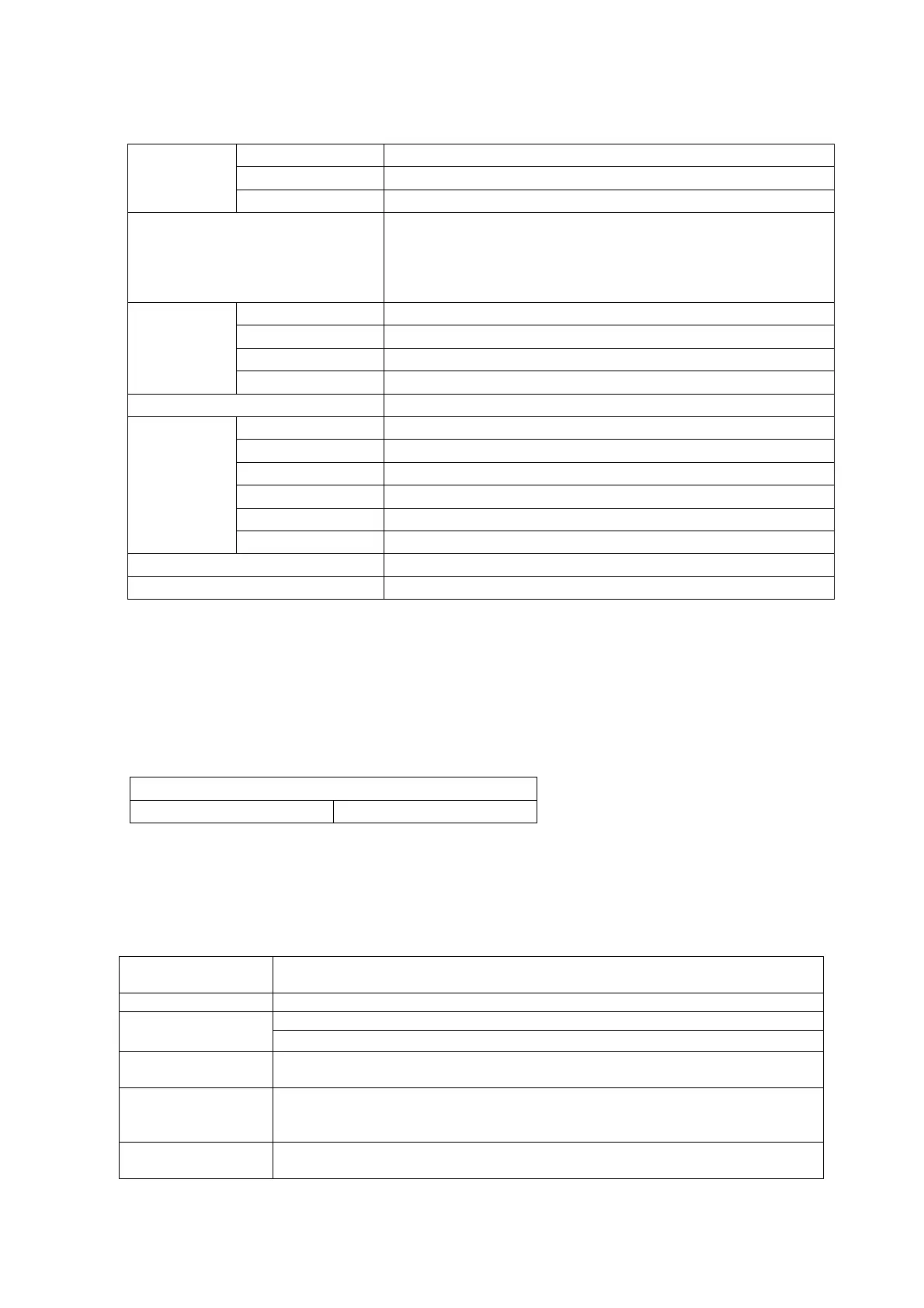

Note2 When the dynamic viscosity of liquids used becomes higher than that in the table below, the useful life of

the motor may become shorter, leading to a burnout. Be sure to use a liquid with a dynamic viscosity

lower than its lime value in the table below. In addition, the dynamic viscosity of a liquid may drastically

increase with decreasing temperature of the liquid. When using a liquid, confirm the dynamic viscosity of

the liquid when its temperature is lowest.

The characteristics of the pump deteriorate as the dynamic viscosity of liquid used increases.

Applicable limit value of dynamic viscosity [mm

2

/s]

Operation at 50Hz / 60Hz 75

Note3 Limit the fluctuations of the power voltage within ±10% of the rated voltage, and also limit the fluctuations

of the frequency within -5% to +3% of the rated value. Avoid continuous operation if the voltage is not

within the range of ±5% of the rated value or if the frequency is not within the range of ±2% of the rated

value.

* This product is labeled with a self-declaration CE mark and complies with the Essential Safety

Requirements (ESRs) of the "EU (EC) Directive. The following are the general descriptions.

Manufacturer

Teral Inc. 230 Moriwake, Miyuki-cho, Fukuyama-city, Hiroshima 720-0003

Japan

Object product VKD-e model coolant pump

Machinery Directive 2006/42/EC

Standards

EN 809/AI:2009、EN ISO 12100:2010、EN 60204-1/A1:2009

Manufacturer

(Japan)

Teral Inc., Hiroshima

Administrator

(EU nation)

Shiran Tower 5F Luzna 716/2 160 00 Vokovice, Praha 6

CZECH REPUBLIC

Person in charge: Tomohisa Yamamoto

Place of declaration

Hiroshima, Japan

Manager: Taiji Monden

*

Loading...

Loading...