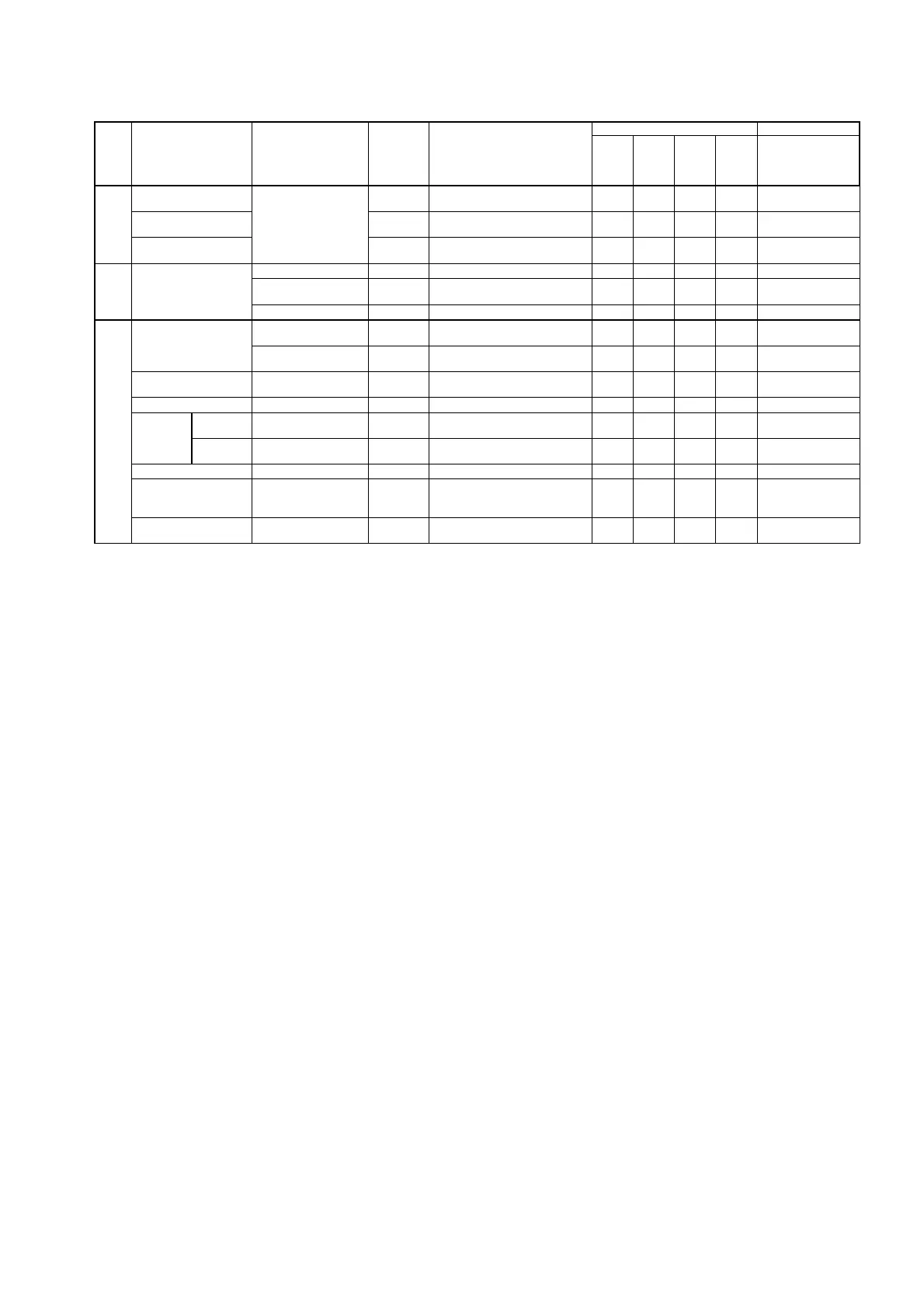

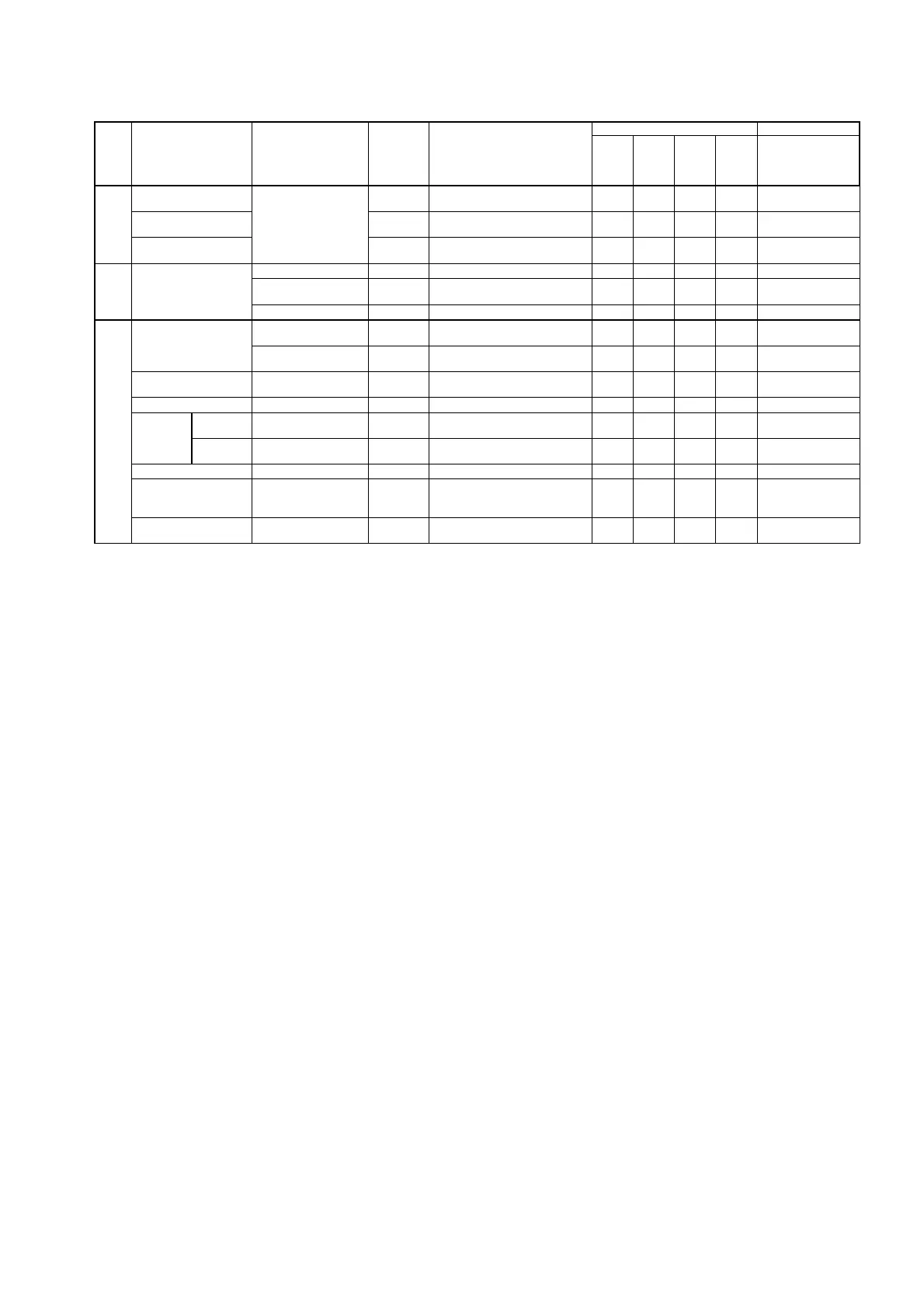

5-3

Maintenance check list

Inspection interval Consumables

Item

Inspection point Check item

Check

method

Criterion

(Reference page)

Daily Monthly

Half-

yearly

Yearly

Timing of

replacement *

1

Temperature Measure -20 to 40°C or less (2-2)

-

Humidity Measure 85% RH or less (2-2)

-

Ambient

environment

Dust, etc.

As per the range in

the specifications

Visual

check

Free of dust or other

contaminants

-

Voltage Measure Specified voltage (2-2)

-

Voltage fluctuation Measure

Within the allowable range of

voltage fluctuation (3-5)

-

Power

Power terminal block

Loose screws Retighten No loose screws

-

Clogging

Inspect after

disassembly

No clogging

-

Impeller

Wear

Inspect after

disassembly

No fault shall be found.

When worn out

Rotate by hand Smooth rotation

Rotate by

hand

Not unusually stiff, Not even in

weight (4-1)

-

Bearing (Motor) *

2

Heating Touch Not unusually hot (5-1)

1 to 2 years

O-rings - - -

Whenever

disassembled

Rubber

parts

Oil seals,

etc.

- - No fault shall be found.

1 to 2 years

Others (screws etc.) - - No fault shall be found.

As needed

Appearance

Unusual noise,

vibration

Hear

Visual

check

No fault shall be found.

-

Pump and motor

Insulation resistance

Between the ground

and each lead

Megger

tester

1 MΩ or more

-

*1 The timing of replacement is not a guaranteed value. The useful life of parts varies depending on

ambient environment and use conditions.

*2 Since urea-based grease is applied for the purpose of a lifetime extension, use urea-based grease

filled bearings.

Loading...

Loading...