09-367 4 - 8 rev 12/98

section 4 OPERATION

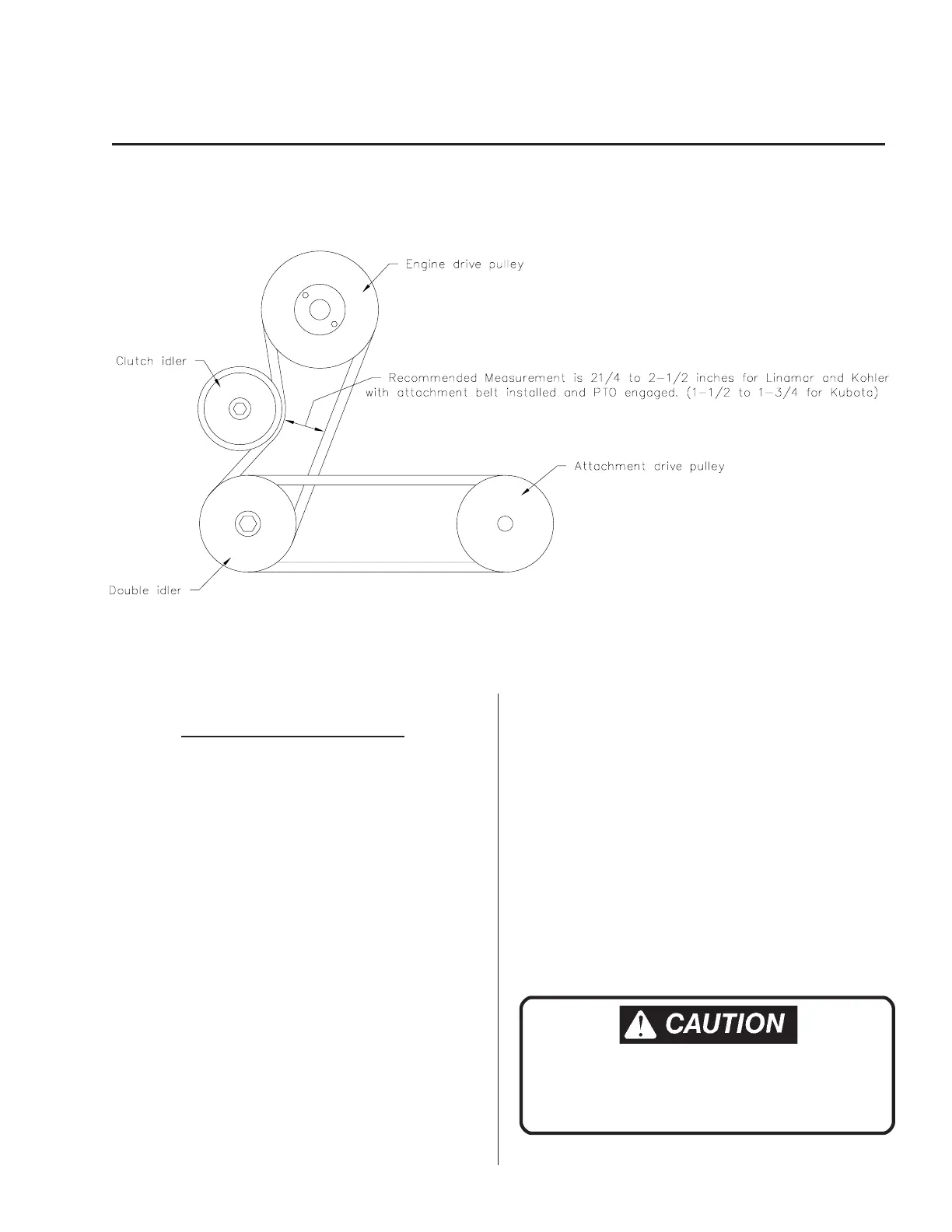

PTO BELT ADJUSTMENT

It is necessary to check the PTO belt adjustment

A. Each time a new attachment is installed.

B. If the PTO drive belt slips or does not release

properly.

1. Attach the new implement using the correct

attachment drive belt. See the Attachment

Operator’s Manual for the correct belt or the belt

chart on page 5-10 in this manual.

2. Stop the engine, engage the PTO lever and check

the distance as shown in above drawing. The

correct distance between the PTO drive belt is

2-1/4 to 2-1/2 inches (1-1/2 to 1-3/4 for Kubota). If

the distance is less than 2-1/4 inches (1-1/2

Kubota) the drive belt may slip. If the distance is

greater than 2-1/2 inches (1-3/4 Kubota) the drive

belt may not release properly when the

attachment is raised to the highest position.

3. Disengage the PTO and adjust the idler slide

assembly by turning the belt release catch handle

clockwise to tighten belt and counter clockwise to

loosen belt. Adjust to obtain the correct

measurement as stated in step 2.

NOTE: If correct measurement is not possible,

check for an improper size drive belt.

4. Start the unit and raise the attachment to full height.

The attachment should not run with PTO

disengaged. If it does, the drive belt adjustment is

too tight. Repeat Steps 1 through 4.

STOP ENGINE! DO NOT ATTEMPT TO INSTALL

BELTS OR MAKE BELT ADJUSTMENTS WITH

THE ENGINE RUNNING.

Loading...

Loading...