Disassembly

and Reassembly

(Flev.

7. 12101)

Repair

l. Inspecl

the oil

pump

coverand housing for daimse md

2. lnspect

the oil

pump

cover and housing for din. debris.

chips, and buffs. Carefully remove

any

contamrnation-

Use a clean shop wipe md solvent

(clean

Stodard

sol

venl

or clean mineral spin$)

and

wipe

the oil

pump

housing nnd

pump

cover clean.

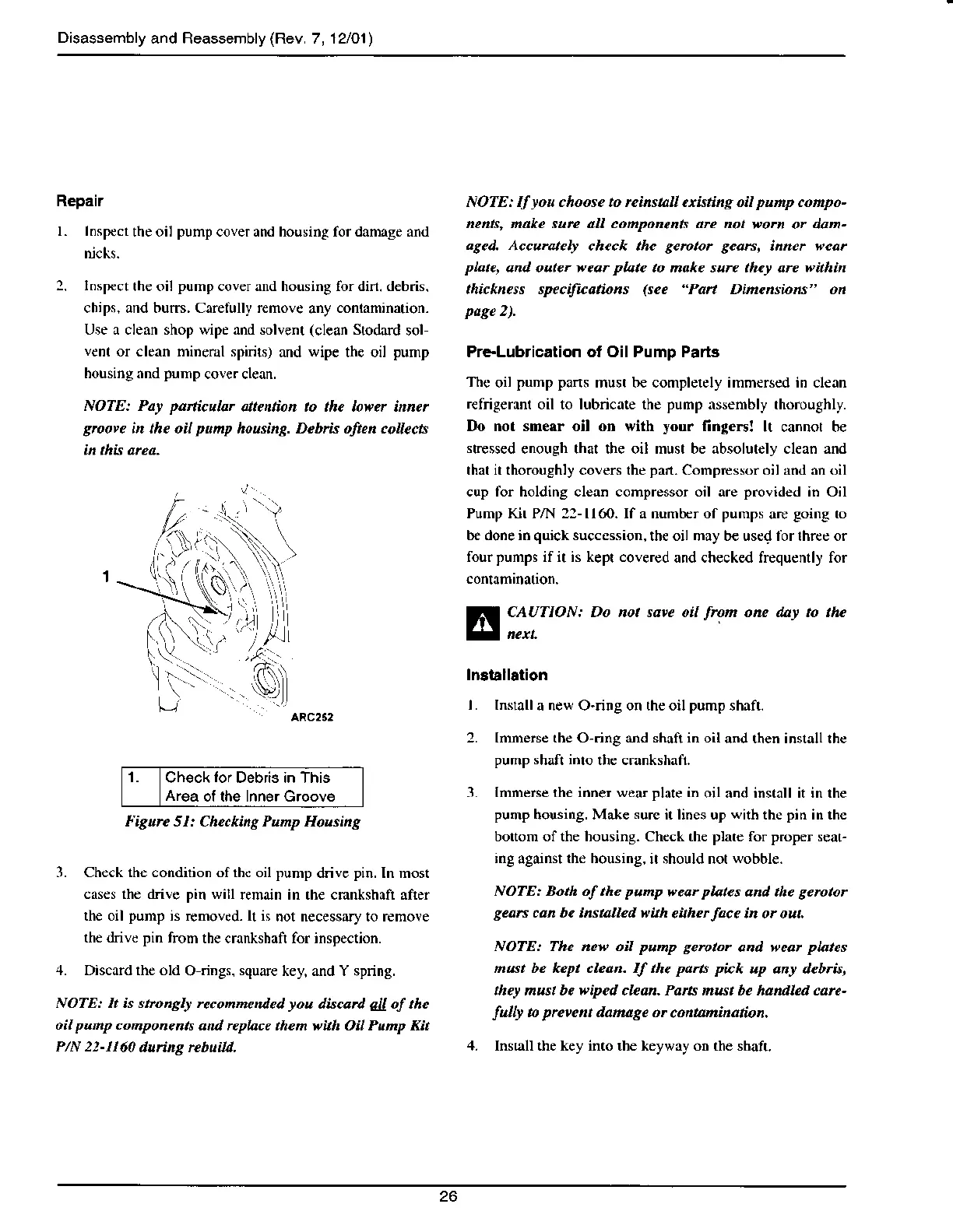

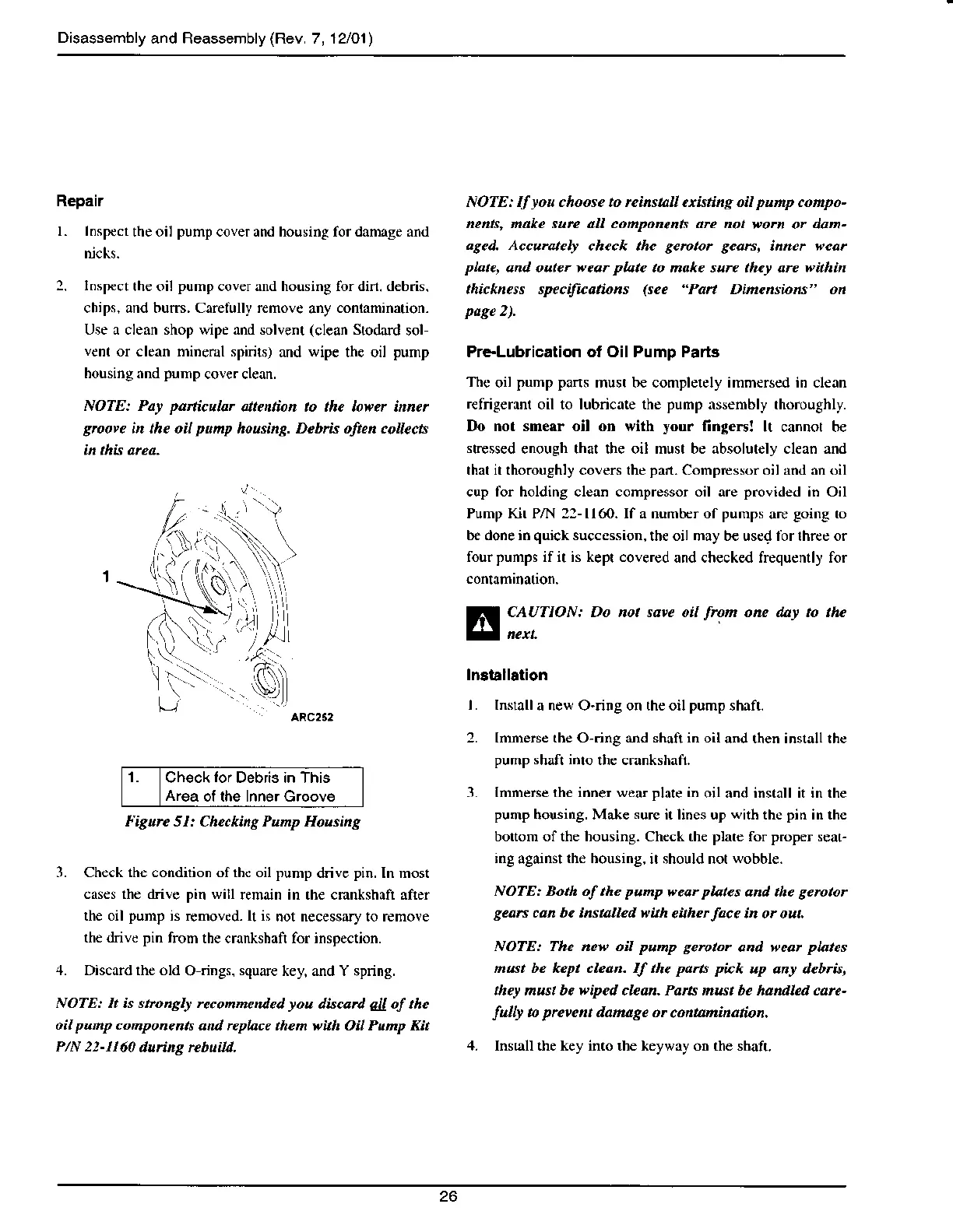

NOTE: Pa!

pa,ttular

dtention to the lover inncr

gmove

in the oil

panp

housinq. Deb* often colkcti

NOTE: II

Jou

choose .o rcinst^ll oxkting oil

pntp

compo-

nents, makc sufe all conponenls are not

wo or dam-

ogetl.

Accuratel| chcck the

Cemtor

gears,

inncr weat

plote,

and outer veor

plate

to nake sun theJ are within

thickness speciieations

(see

"Pad

Dimensions" on

page

2).

Prc-Lubrication ot Oil Pump Parts

Thc

oil

pump pans

must be completely immersed in clean

refrigeranl

oil to lubricate the

pump

nssembly thoroughly.

Do no. smear oil on with

your

finge.s!

lt cannot be

stressed

enough thar the oil must be absolutely clean and

that it thoroughly covers the

part.

Compressor oil and an oil

cup for holding clean compressor oil are

provided

in Oil

Pump Kir P,4'{ ::-ll60. If r numbcr of pumf\ .r. going ro

b€ done in

quick

succession,

the oil may b€ used lbrlhree or

four

punps

if it is keF covered

and ch€cked frequenlly for

CAATION: Do no. save oil

fron

one dal t'

thc

Inatallalion

L lnstall

a new O-ring on the oil

pump

ihaft.

2. Imnerse the O-ring nnd shaft in oil

and then inslall lhe

pump shafi inlo

the crankshaft.

1.

Check

lor

Debris in This

Area

of the lnn€r Groove

F-igurc 5I: Chocking Punp Housing

Immerse the inner wear plale i.

oil and install it in lhe

punp

housing. Make

surc

it lines up

with

the

pin

in the

boltom ofthe housing. Check the

plate

for p.oper seat-

ing

againsr

lhe housing,

it should not

wobble.

NOTE: Both of he pump

v'ear

plates

and the

gerotor

g.afs

can he insta e.l wilh

either

face

in or ou..

NOTE: The nc$' oil punp

serotor

ond wear

plltes

must be kept clean. Il the pa.tt pitk

up anr de,'.is,

ther nust be wiped clcan- Pa|A must be hannled care-

fulb

ta

prevent

dan age or

contamindion.

Insrall the key into rhe keywry on the shafr.

-t.

3. Check the condition ofth. oil purnp

drive

pin.

In most

c$es the drivc pin will

remain in rhe cnnkshaft after

the oil

pump

is removcd- 11 is

not necessary to remove

$e drivc pin from

the crankshafr for inspectron.

L DNLfld thc old O nngs.

'qurre

ley. Jnd Y

spring.

N0TE: It is stronslr reconnended

Jou

dircad

ellof

thc

oil punp conponena

and rcplace them N'ith Oil Punp Kit

P/N 22-1160

durinq rchuiu.

26

Loading...

Loading...