Disassembly

and Reassembly

(Bev.

7, 12l01)

13.

15.

14.

16.

NOTE: The

punp

corer

and outet vear

plate

must be

ctean and

Irce

ot debris.

Install rhe oil

purnp

cover bohs and

washers.

Torque the

oil

fump

(orer/housing

bolt. In lso sr(p\ uring J

criss-cross

paltem

(see

Torque Vrlues' on

page

+,.

Immerse new

O-rings in oil and inslall rhem on the oil

pressure

reliefvalve

and the oilpickup

plug.

Inslall

the oil

pressure

rclief valve and the oil

pickup

plug

(see

"Torque

Values

on

page,l).

Install any addniond oil fittings

thal may hav€ been

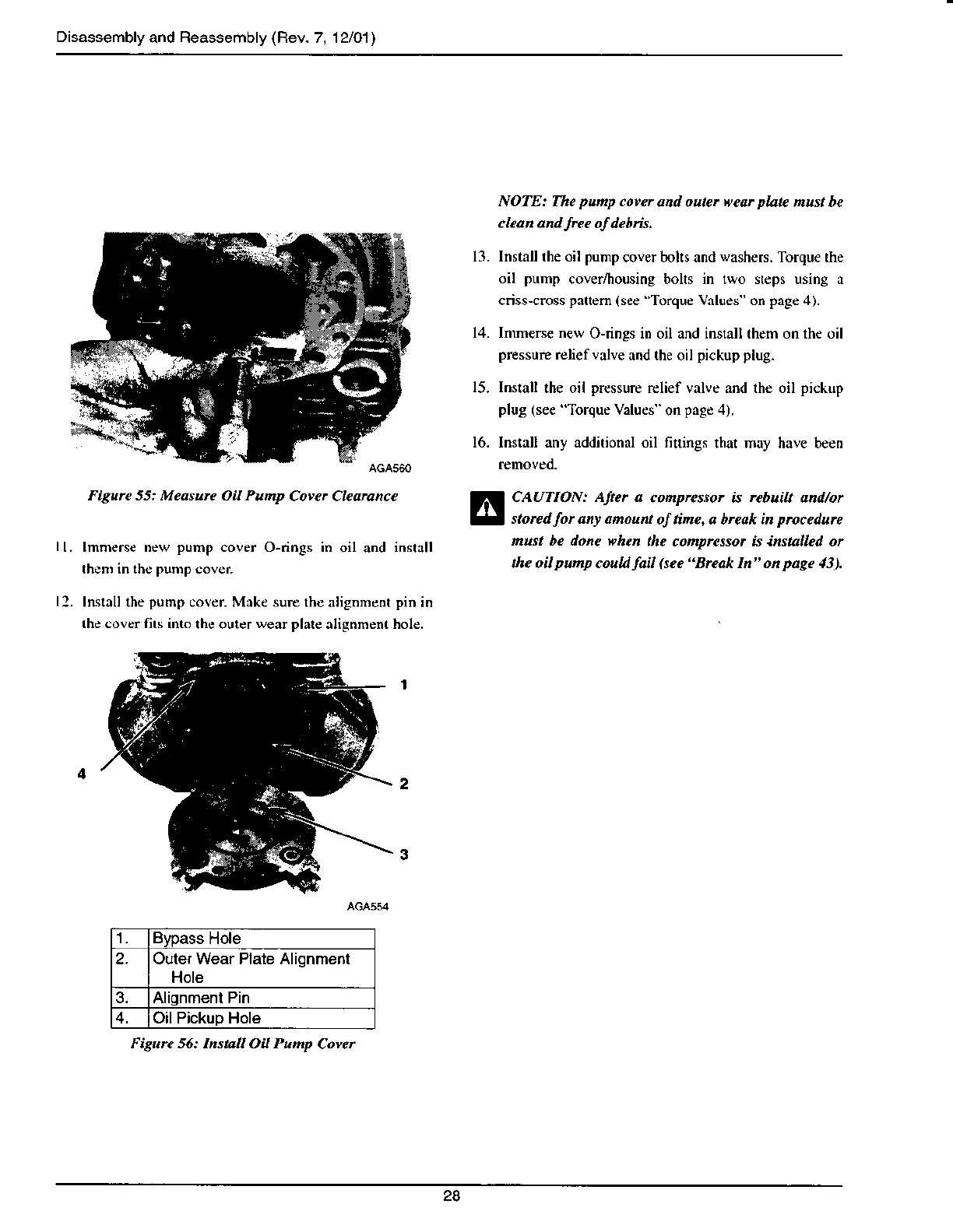

t2.

Figurc 55: Measure OiI Punp

Cover Clesrunce

lmmers€ new

pump

cover O-rings in

oil and

install

then in the

pump

cover

Inshll the

pump

cover. M:rke sure thc

alignm€nt

pin

in

the coverfits into

lhe outer

wearplate

alignment hole.

CAUTION: AJter a

compftssor is

rcbuib

und/or

stored

lot

any anount

o! time, a brcok in

prccedurc

must be done vhen

the conpressor is installat or

the oil

punp

couu

fail

(see

"Break

In" on

pace

13).

1 Bypass

Hole

2. Outer Wear Plate Alignment

Hole

3. Alignment Pin

4. Oil Pickup Hole

Figure 56: Insbt OiI Pump

Coyer

28

Loading...

Loading...