Disassembly

and Reassembly

(Rev.

7, 12101)

CONNECTING BOD,

PISTON AND

SLEEVE

Removal

l. Removc rhc cylindcr heads

((see

Cylinder Hcad on

prsc

ll)-),

the discharge

valvc

plares

(lsee

Discharge

Valvc Platcs on page

l:).) nnd the oil sump

and the oil

p'ckup

screen

((see

Oil Sunp

and Oil

Pickup

Scre€n"

on

pagc

13).).

L

Renlole the connecting rod

nuts.

Repai.

l. Rfnk,\c the pi.lon

d rod rrum the \lceve.

2. Insped thc

sleeve for scoring. danagc or

cracks near

the

pons.

Tbe cross hatching or honing nrarks

should

still

be

visible

in the sleeve. There

should be no large

scralches

in the sleeve.

3. lnspect

the

piston

for wearand dinrrge.

Check for largc

scratches in thc

pislon

surfaces.

4. Measure

pisron

and

the

sleeve.

lf the

piston

or sleeve

nre wom beyoDd

the maximum allowablc opcmring

cleffance shown

in Operaring Clcarances

onpagcl.

they

should

be replrced.

.1. Tap lhc conncction nl

cap

lightly with

a sofi halnmcr

l0 krcsen it arom the rGl.

Rcnrove

lhc

pislon.

rod md slceve as an

ass€mbly from

lhc cylinder and keep thcm in se1s.

This will aid in the

c!irluntion of the compoDcnts.

CAUTION: The.e

arc no marks on the ro^

and cops that

Uetrtdy them as sets. but thc!

nust be

kept

in matchcd se*. It

is helplul k

Figure 57: Pltton and

Sleeve Renowl

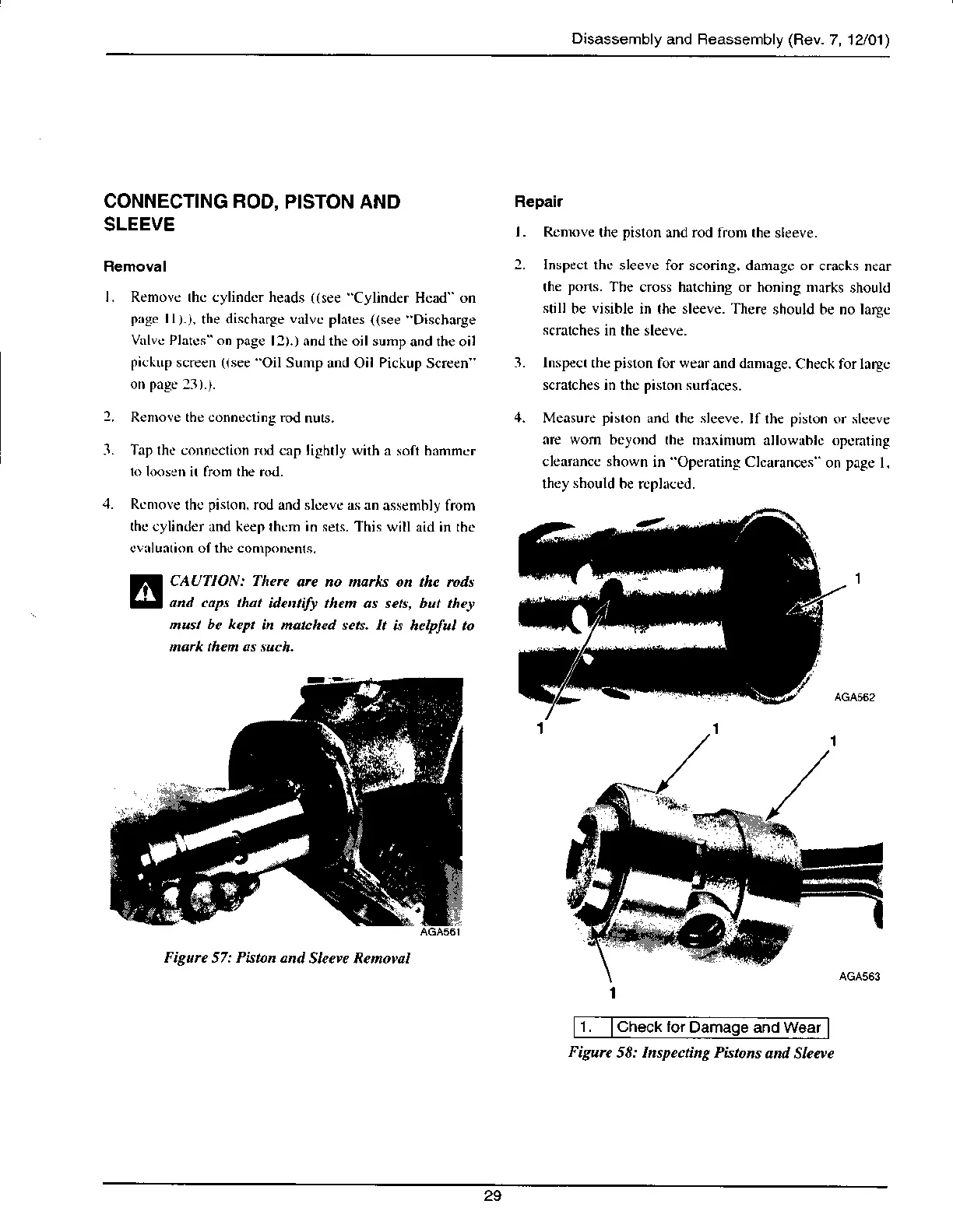

1.

lCheck

lor

Figure

58: Inspecting Pistons

and Sleeve

29

Loading...

Loading...