Disassembly and Reassembly

(Rev.

7, 12l01)

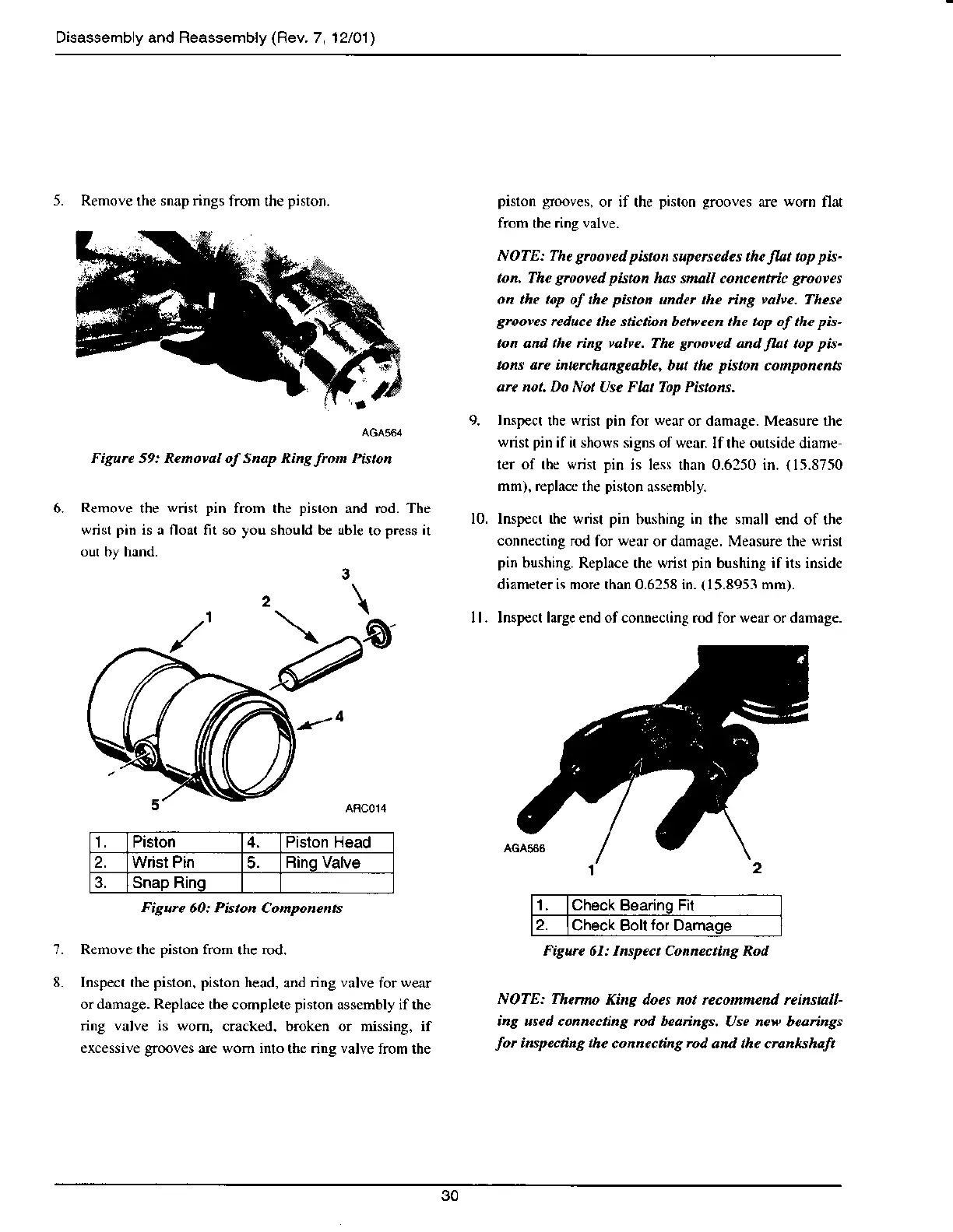

5. Remove

the

snap nngs

from.he

piston.

AGA564

Ficure s9: Rernoval of snap Rins

lrott

Piston

piston grooves,

or if the

piston grooves

are

worn

flat

NOTE: Thc grooved piston

supe$edes the

fiet

tap

pk-

ton. The

gmoved pltbn

has sna co centric

crooves

on the top o! the

pisron

undu thc nng wlve. Thcse

grooves

redue the snctian betveen the top of thc pis-

.on and the ing valve. The

smovcd

and

fut

top

pis-

tons arc interchangeable,

but thc

piston

components

arc not Do Not Usc Flat Top Pktons-

Inspect

the

wrist pin

for

werr

or damage. Measure the

wrist pin

if n shows signs of wear.

Ifthe oulside diame

ter of rhe wrisr pin

is less than 0.6:50 in.

{15.8750

min), replrcc fie piston

assembly.

lnspccr $e wrist

pin

bushing

in

lhe

small

end of the

connecring rod

for

wear

or damage. Measure the

wrist

pin

bushing. Repla€e rhe wrisr

pin

bushing if its inside

diameler is more than 0.6258 in.

(

15.8953 mm).

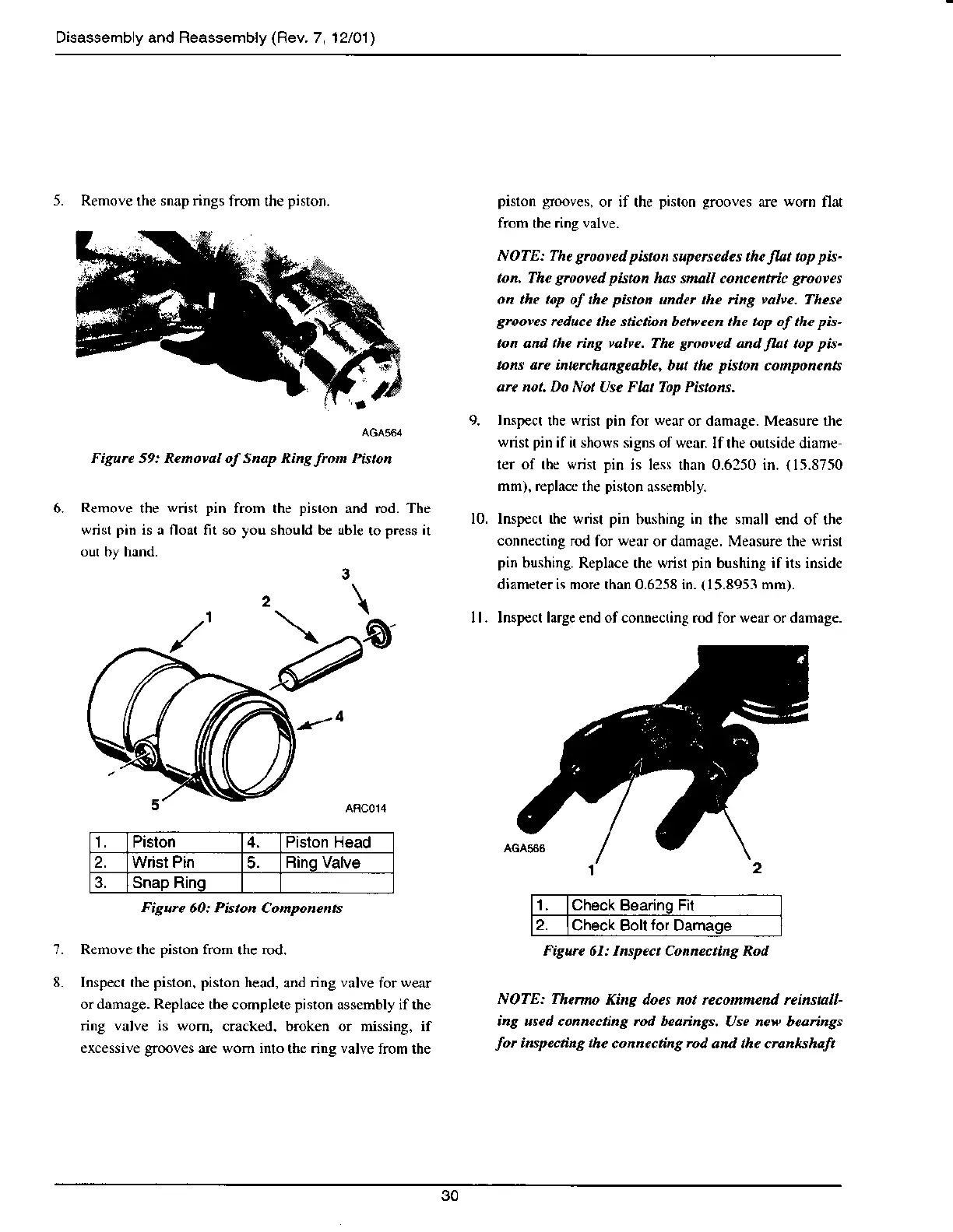

lnsp€ct large end ofconnccring rod

for

wear or damage.

Remove

the

wrisl pin

from the

piston

wrisr

pin

is n floar fit so

you

should be

our by hand.

10.

9.

lt.

Piston Piston Head

2. Wrist Pin Binq Valve

3. Snao Rino

Figure

60: Piston Conponcn6

I Check

Bearinq

Fil

2.

Check Boll

for

Damaqe

Irigure 6I: Inspect Connecting Rod

,7

8

Remove the

pislon

from

the

rod.

Inspect the

piston, piston

h€ad,

and

nng valve

tor

wear

or damige. Replace

the complete

piston

assembly if rhe

nng valve is wom,

cracked. broken or missing. if

excessive

grooves

are wom into

the

ring valve

from the

NOTE: Thermo

King does not recomment rcinstall-

ing used .onnecring ftd bearings.

Use

new

b?anngs

for

inspocnnC

&e connecting rcd and &e crunkshaft

30

Loading...

Loading...