Disassembly

and Reassembly

(Rev.

7, 12101)

r:.

t:t.

Place the bearing in the rcd. k should fit into

the

rnnchined radius snugly wh€n pushed with

lhe thumb.

Whcn thc b.aring is

bo(omed our both ends of the

bcanng should be flush u,ith

the mating surfn€es ofrhc

rod. The bearing

should fi1inlo the rod cnp in the sanre

NOTL: Be sure

to olign the .tbs in the bearings dth

the notches in the mating

pa

s.

Check the cnnkshaft assembly for

free rotalron

rftereach

connecting has been

properly

righlened.

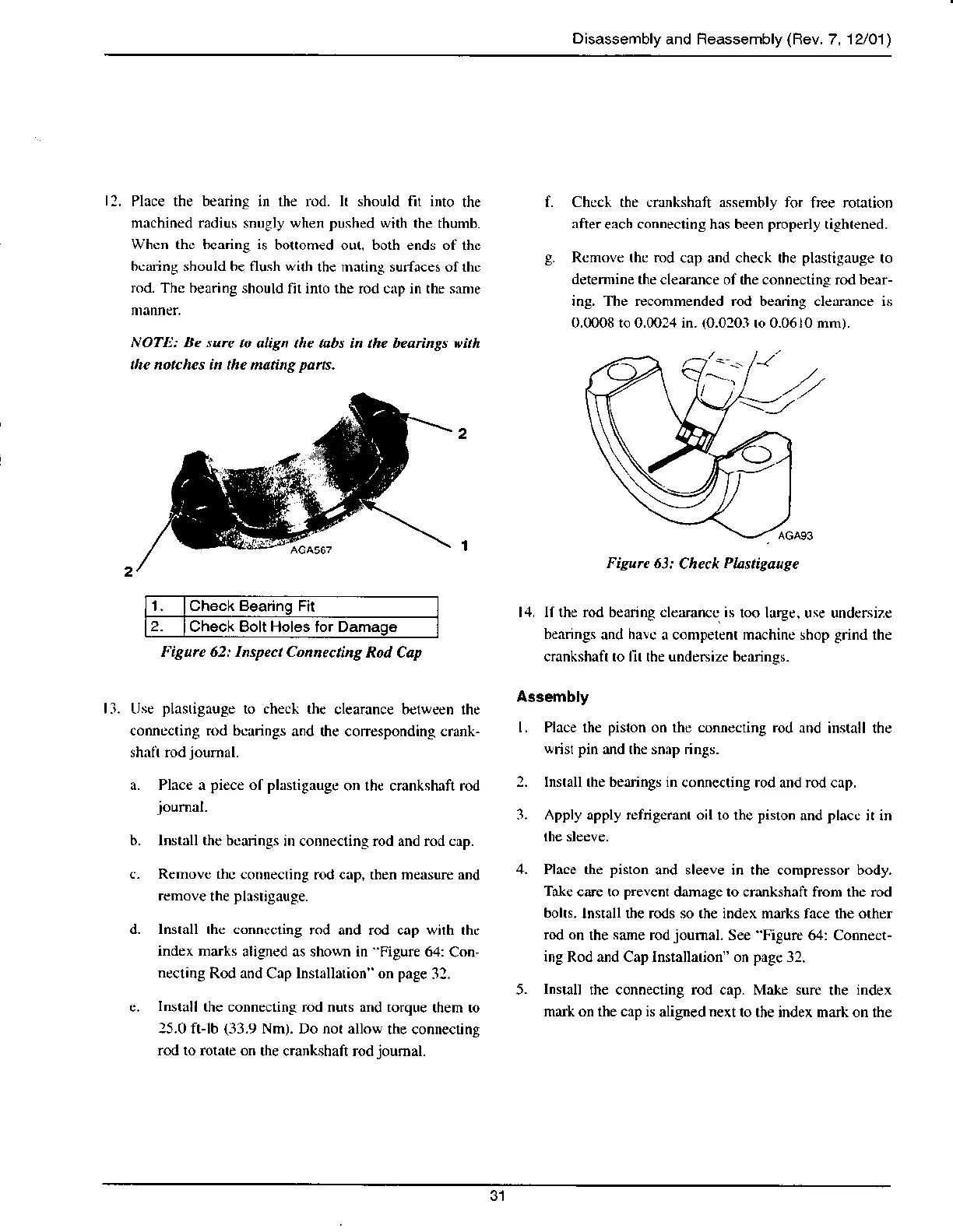

Renove the rcd

cap and check the

plastigauge

ro

detemine

theclearance ofthe connecting rod bear-

ing. Th( Rcommended rod b(xnng.l(Jrin(e n

0.U)08 to 0.0024 in.

(0.0201

ro 0.0610 lnm).

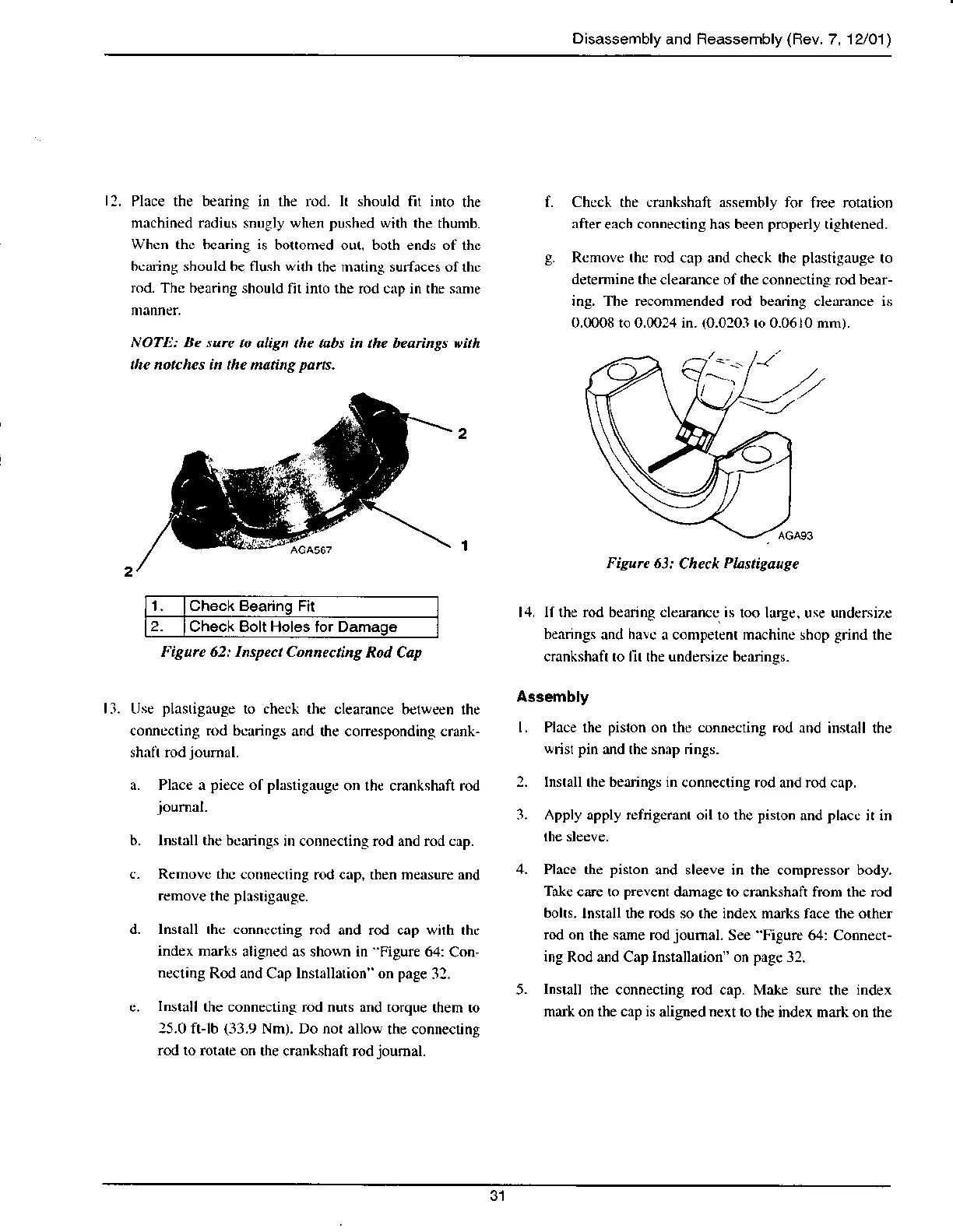

I.

t. Ch6ck Beadnq Fit

2.

Check Bolt Holes lor Damaa€

F-igurc 62: Inspect Connecting

Rod Cap

Fisurc 63:

Chcck

Plastigauge

14. If the rod bearing clcarancc is

loo l

gc,

use undcnrzc

bearings

and

halc

a compelent machine shop

grind

the

crankshaft to lit the undersize bcllrings-

As3embly

L Place the

pislon

on thc connccting rod

and install the

wrisl pin

and the snnp rings.

:. Install rhe bearings in

connecting rod and rod cap.

3. Apply apply refrigernm oil

to lhe

pislon

and

placc

it in

4. Place the

piston

and sleeve in lhe compressor body.

Take

care to

prevent

damage lo crankshaft from the rod

bolts.

lnstall the rods so the index marks face the other

rod on

the

same

rod

joumal.

See

"Figure

6.1: Connect-

ing Rod and Cap Installarion" on

page

32.

5.

Insrall

the connecting rod crp. M*e sure

lhe

index

mark on the c:tp is

aligned

next

to the index mark on the

tise

plasrigauge

ro check the

clearanc€ between the

connecting rod bcrrings

and the conesponding crmk-

a. Place a

piece

ot plasrigrugc

on th€ crankshafl rod

b. lnstrll th€

bcarings irr conne€ting rod and rod cap.

c- Rcmovc thc

connecting rod cap, rhen measure and

rcmove

the

plastigauge.

d- lnstall rhe connecting

rod and rod cap wirh rhc

index marks

aligned as shown in Figure 64:

Con,

necting

Rod and Cnp lnslallarion" on page

31.

e.

Install

the connecling rod nuts and iorque

them ro

15.0 ft-lb

(33.9

Nm). Do not allow

th€ connecting

rod to rorate on

the crankshaft rod

joumal.

Loading...

Loading...