Disassembly

and Reassembly

(Rev.7,

12101)

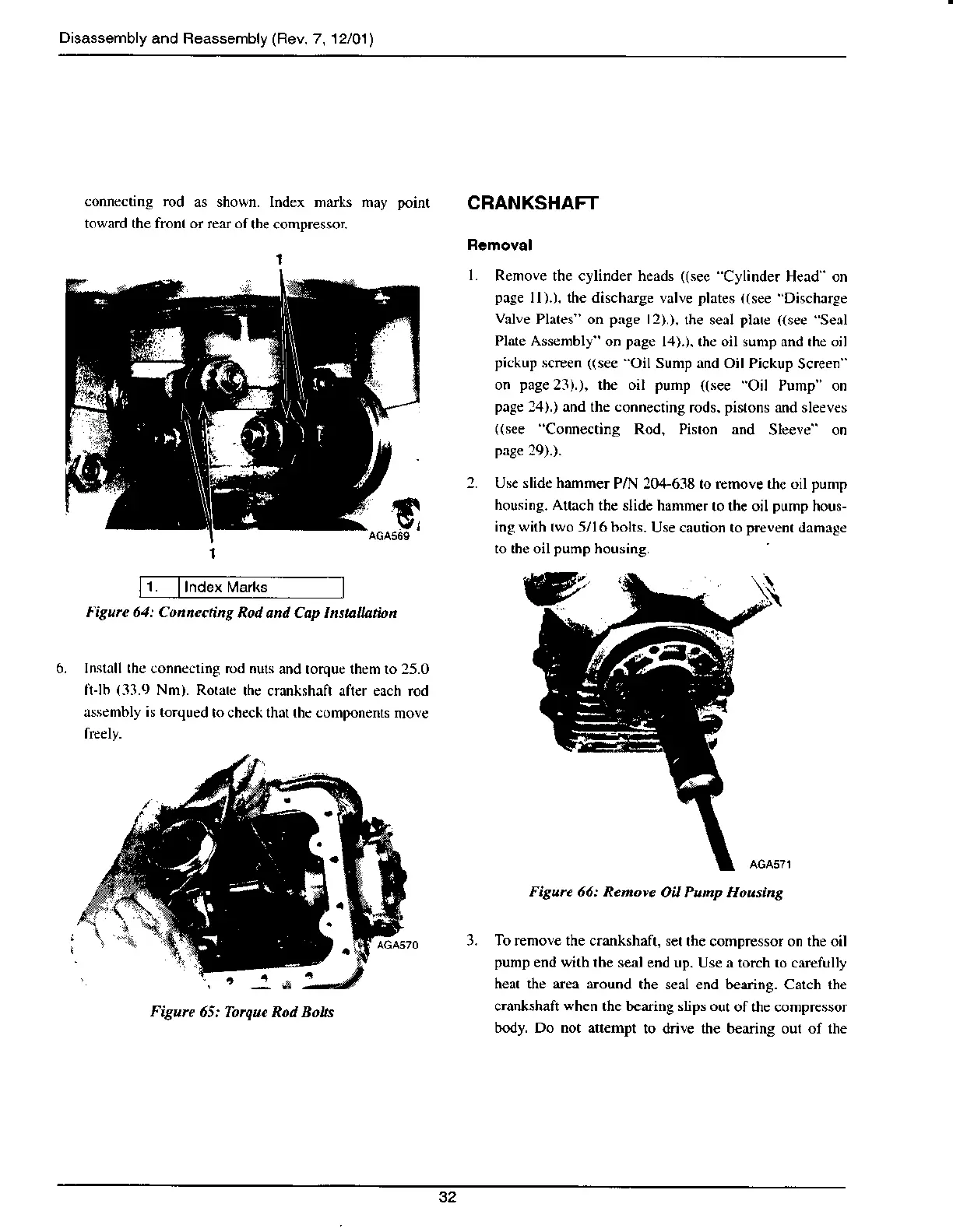

connecting rod

as sho$'n. lndex marks

toward the fiont or rear of

the compressor.

CRANKSHAFT

Rcnoval

l-

Remove the cylinder heads

((sec

Cylinder Head on

page

ll).). the dischirge valve plates

((see

Dischnrge

Valve

Plales" on

page

l2).),

the seal

plare

((see

Seal

Plate Assembly"

on

page

l,l).). the oil sump and rhe oil

pickup

screen

((see

"Oil

Sump and Oil Pickup

Screen'

on

page

2l).), the oil

punp

((see

Oil Punp" on

page:4).)

and the connecting

rods.

pistons

and sleeves

((se€

'Conn€cting

Rod, Piston and

Sleeve on

page

29).).

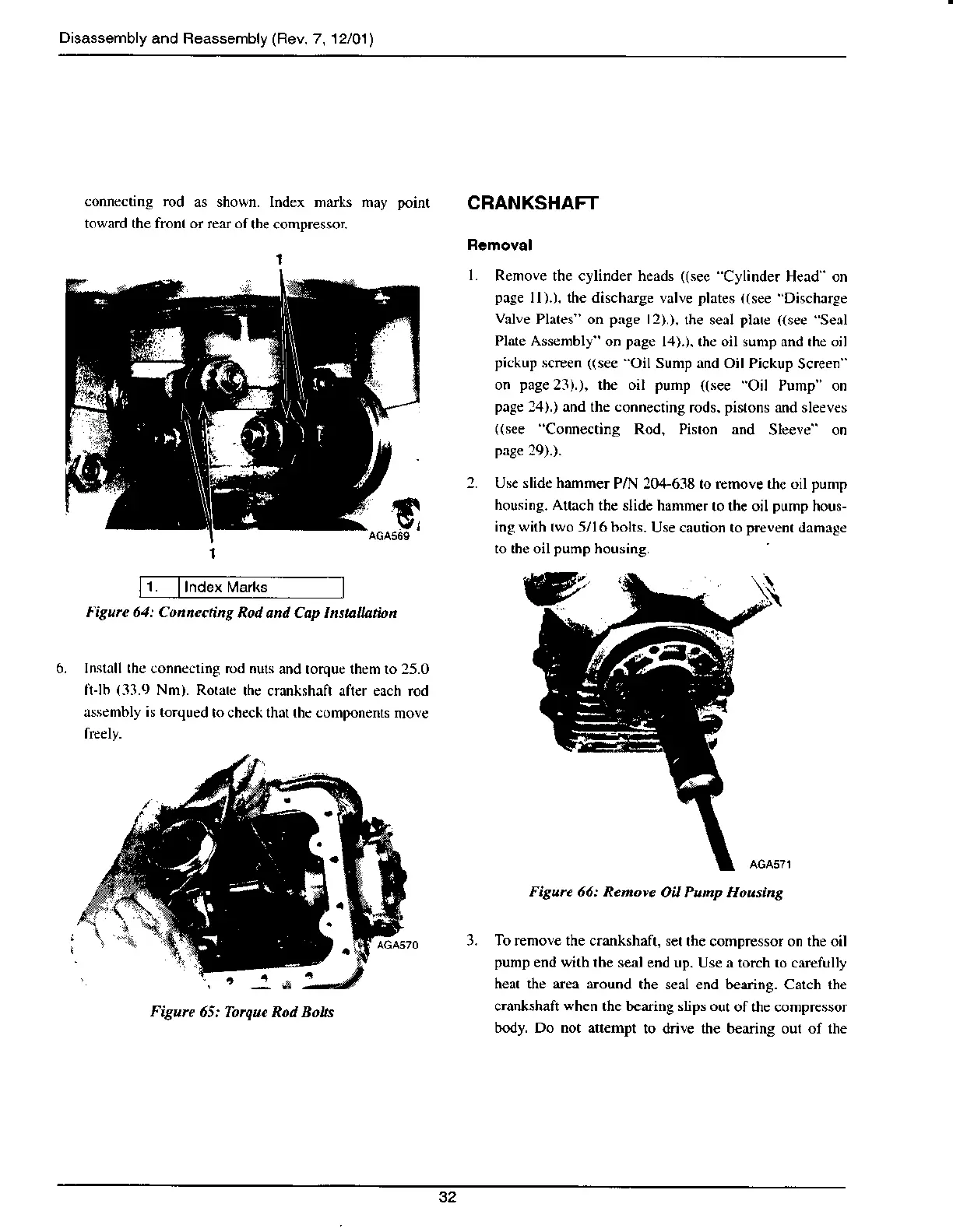

2. Use slide hamm€r

PN 20+638 to remove thc oil

punp

housing. Auach

the slide hamme.

ro the oil

pump

hous-

ing

with

lwo 5/16 bolts.

Use caution to

prevent

damrge

to th€ oil

pump

v;

I'igurc 61: Connccting

Rod and Cap Insta ation

Install lhe connecting rud nuls

and rorque them to 25.0

lilb

(13.9

Nm). Rot e

the crankshaft afl€r each rod

Nsembly is torqued

toch€ck th

rhc comF)nenb

move

treely.

1.

I lndex Mafts

Figure 66: Remove

Oil Punp Housing

To remove the crankshaft, set

the compressor on the oil

pump

end with rhe seal

end up. Use a torch.o carefully

heat the area nound

the seal end bearing. Catch the

crantshaft

when

the bearing slips out

of the compressor

body. Do not a[empt

to drive the b€aring out of the

Figure

65: Toryue Rod Bolts

Loading...

Loading...