2

Thermo Scientific Revco Laboratory Refrigerators Installation and Operation

4 Installation

Do not exceed the electrical and temperature ratings.

CAUTION! Improper operation of the equipment

could result in dangerous conditions. To preclude

hazard and minimize risk, follow all instructions and

operate within design limits noted on the dataplate.

4.1 Location

Install the unit in a level area free from vibration with a minimum

of 6 inches of space on the sides and rear and 12 inches at the top.

Do not position the equipment in direct sunlight or near heating

diffusers, radiators, or other sources of heat. The ambient

temperature range at the location must be 59 to 90°F

(15to32°C).

4.2 Wiring

CAUTION! Connect the equipment to the correct

power source. Incorrect voltage can result in severe

damage to the equipment.

DANGER! For personal safety and trouble-free

operation, this unit must be properly grounded before

it is used. Failure to ground the equipment may cause

personal injury or damage to the equipment. Always

conform to the National Electrical Code and local

codes. Do not connect unit to already overloaded

power lines.

Always connect the equipment to a dedicated (separate) circuit.

Electrical codes require fuse or circuit breaker protection for

branch circuit conductors. Use time delay fuses for #12 AWG

circuits.

Chromatography refrigerators are equipped with a duplex vapor-

proof interior outlet with a maximum of 4 amps per receptacle.

The wiring schematic is attached to the back of the cabinet.

4.3 Leveling

It is important to make sure the unit is level. Use thin sheets of

metal to level units equipped with casters.

Undercounter models come with leveling feet installed, with

casters provided in a bag inside the cabinet. The unit must be

level. To level undercounter units, rotate the leveling screws,

located under the front corners of the unit, until the unit is level.

If the floor is seriously out of level, you may need to shim the

corners with thin sheets of metal.

4.4 Door Seal

To check the door seal, complete the following steps:

1. Open the door.

2. Insert a strip of paper (a couple of inches wide) between the

door gasket and the cabinet flange and close the door.

3. Slowly pull the paper strip from the outside. You should feel

some resistance.

4. Repeat this test at 4-inch intervals around the door. If the

door does not seal properly, replace the gasket.

CAUTION! Door seal integrity is critical for

refrigerators and freezers. A loose fitting gasket allows

moist air to be drawn into the cabinet, resulting in

quicker frost buildup on the evaporator coil, longer

running time, poor temperature maintenance, and

increased operation cost.

4.5 Door Operation

Solid doors and standard glass doors for models larger than the

undercounter model stay open if opened 90 degrees. Door spring

tension cannot be adjusted.

If the self-closing doors do not work properly, make sure the unit

is level.

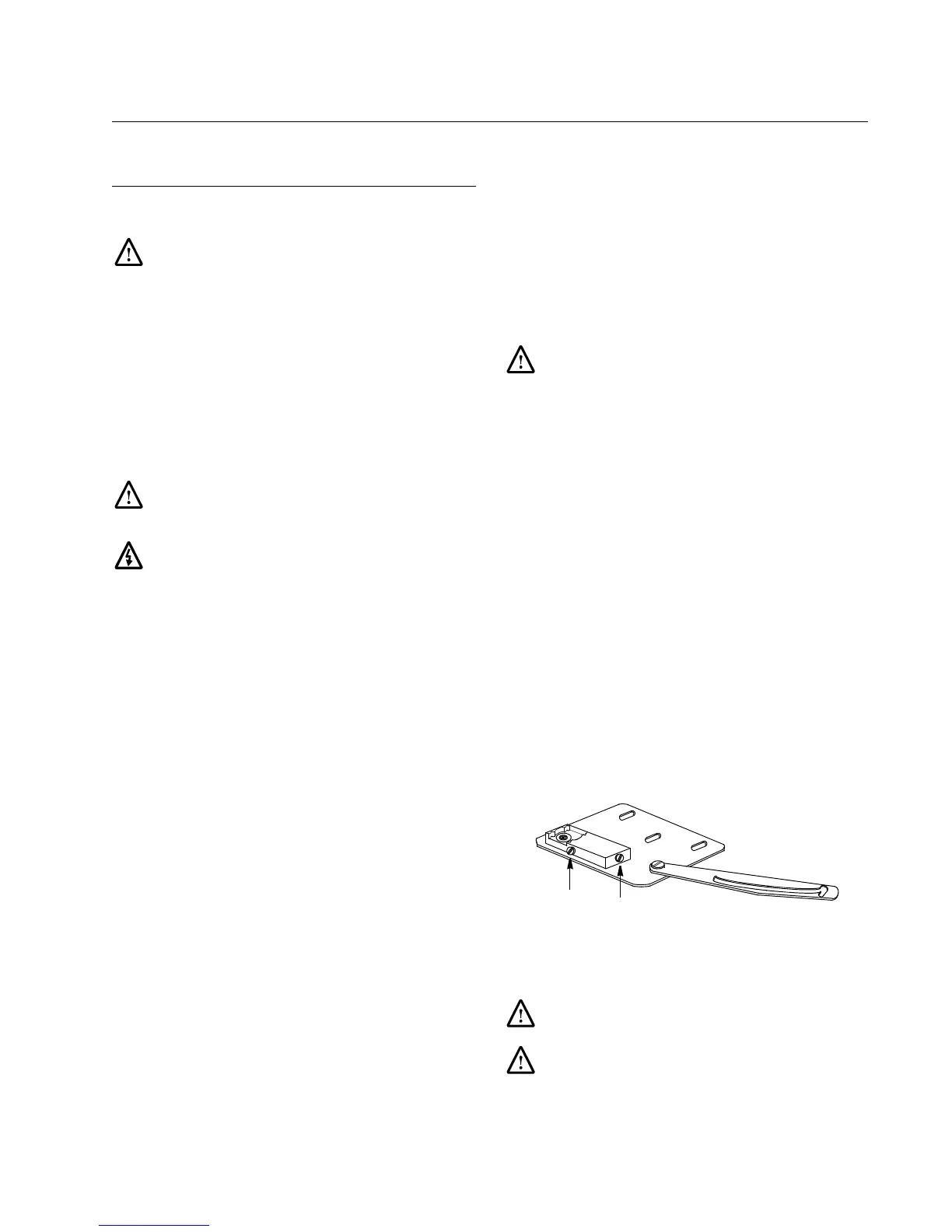

4.5.1 Adjustable Hinged Glass Doors (Undercounter

Models Only)

On undercounter models with hinged glass doors, you can use a

regular screwdriver to adjust spring tension and center each door

on its frame. The adjustment screws (“torque” for tension and

“sag” for door placement) are located on the bottom hinge

bracket (shown below in Figure 1).

Hinged glass doors can be propped open with metal braces at the

bottom hinges. Open the door 90 degrees or until you feel some

resistance. Push the door open past the resistance and the metal

braces engage. To close the door, push it toward the unit (past the

resistance).

Figure 1. Undercounter Hinge Bracket for Glass Door

Adjustments

CAUTION! Do not overtighten the tension as

damage to the equipment can result.

WARNING! Disconnect equipment from main power

before attempting any maintenance to equipment or its

controls.

To rq ue

Sag

Loading...

Loading...