thermopatch.com

12

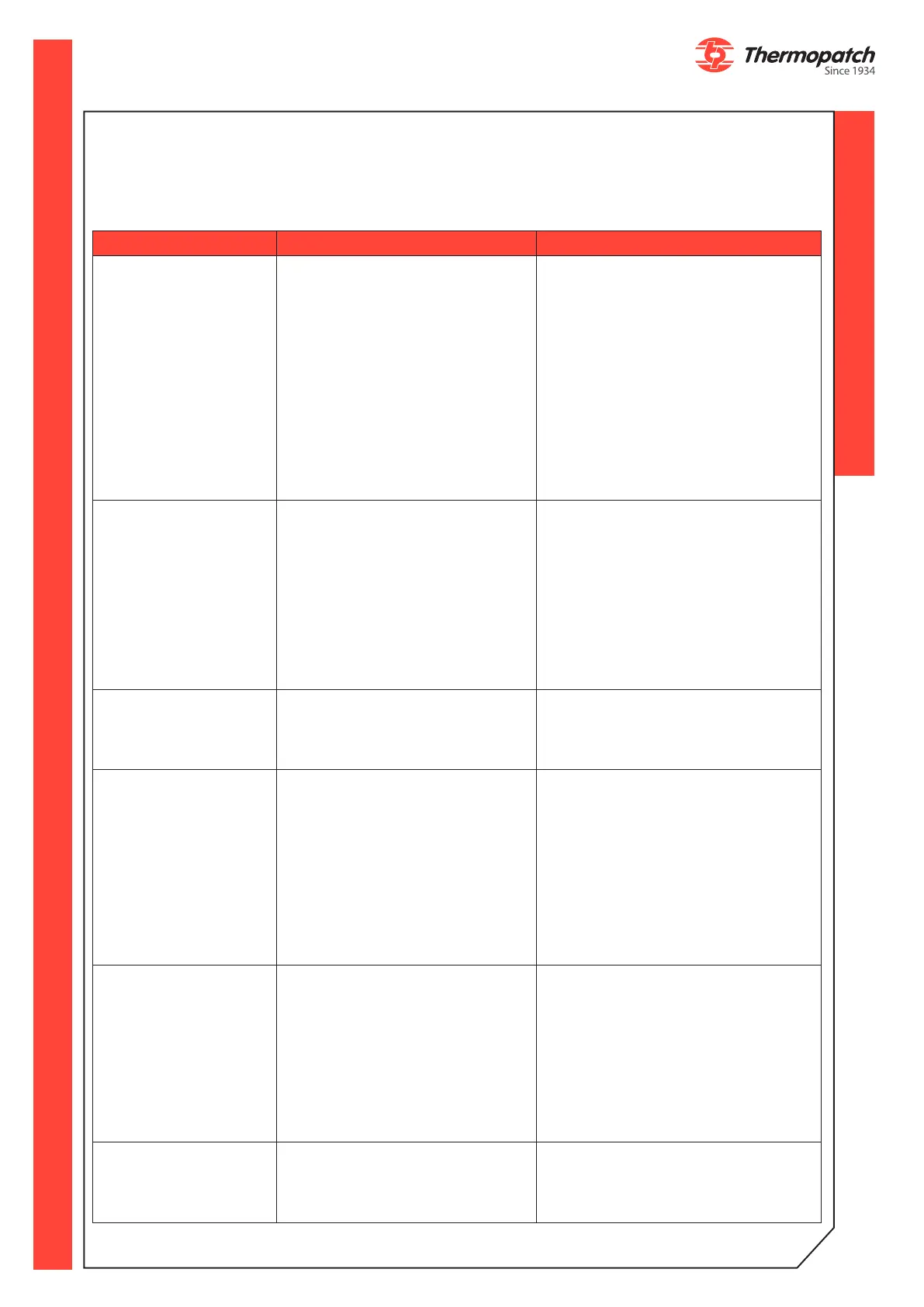

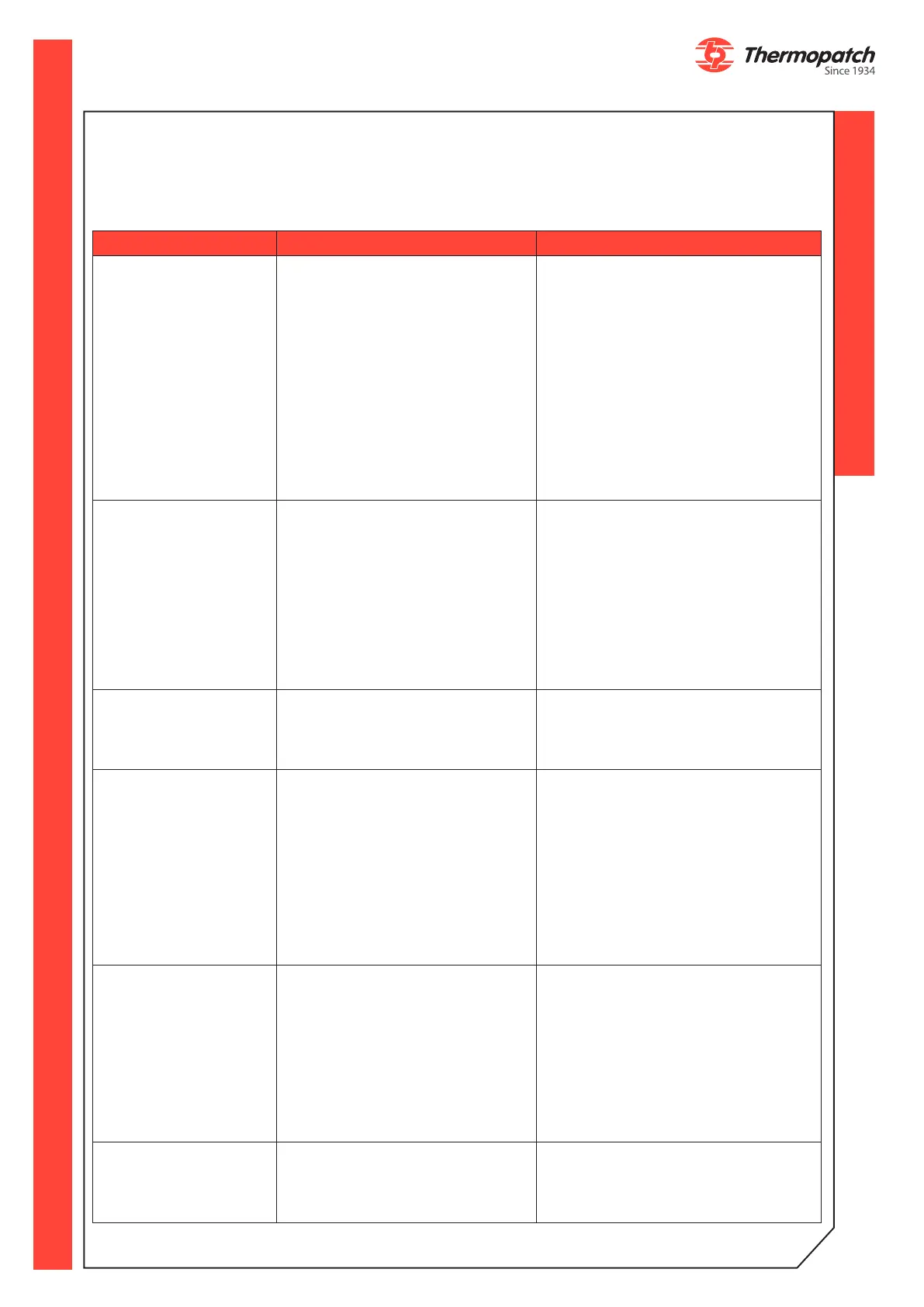

9. Technical annexes

9.1 Faults:

Fault Possible cause Solution

No heat.

• Machine is unplugged or

power source is faulty.

• Main power switch is not

“On”.

• Power Saver feature

activated.

• Temperature displayed.

• Loose wires.

• Heat sensor is defective.

• Sealing iron is defective.

• Relay is defective.

• Heat controller is defective.

• Check plug and fuses.

• Check

• See I. Introduction.

• See II. Installation.

• Check

• Replace

• Replace

• Replace

• Return circuit board to

factory for repair.

Temperature too high

or too low.

• Heat control requires

adjustment.

• Temperature display is

incorrect.

• Power Saver feature

activated.

• Heat sensor is defective.

• Sealing iron defective.

• Heat controller is

defective.

• See II. Installation to adjust.

• See II. Installation to check.

• See I. Introduction..

• Replace

• Replace

• Return circuit board to

factory for repairs.

Time malfunction.

• Loose wires.

• Timer is defective.

• Micro switch is defective.

• Check

• Return circuit board to

factory for repairs.

• Replace

Handle does not stay

down. Handle does

not return at end of

cycle (HS-4-C).

• Insucient pressure

• Excess pressure.

• Motor is defective.

• Linkage or gas spring is

binding or broken.

• Springs are weak.

• Links broken.

• See III. Operating the

HS-4-C.

• See III. Operating the

HS-4-C.

• Replace

• Lubricate or adjust. See Page

V. Possible faults

and VI. Supplies Note 1.

• Replace

• Replace

Inadequate bond or

transfer.

• Insucient sealing time

• Insucient pressure

• Insucient tempeature.

• Pad worn.

• Teon shield soiled or

worn.

• Increase time in 2 second

increments and test.

• Increase pressure in one half

turn increments and test.

• See II. Installation to adjust.

• Replace

• Clean or replace.

Bleed through.

• Too long sealing time.

• Too much pressure.

• Decrease time in 2 second

increments.

• Decrease pressure in one half

turn increments.

AA

Loading...

Loading...