3-13

AXLE ASSEMBLY 3.6

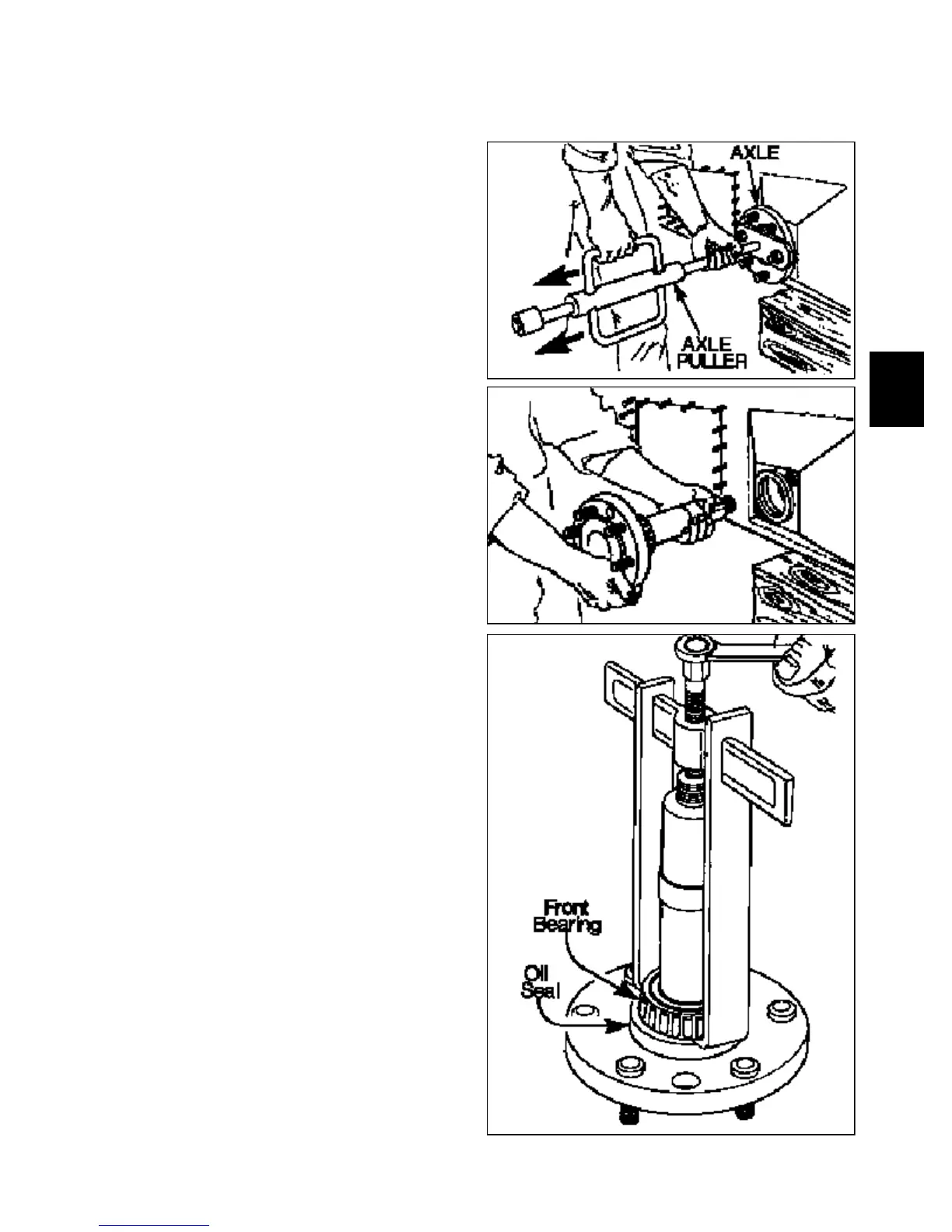

15 Attach a special axle puller tool, Thomas P/N

955283, to the axle flange wheel studs using the wheel

nuts that are on the loader. (fig. C228)

16 Using the slide hammer action of the special puller,

remove the axle. The rear bearing and axle sprocket will

remain in the final drive housing.

17 Remove the axle sprocket and bearing from the final

drive housing through the inspection cover area.

C228

C220

C221

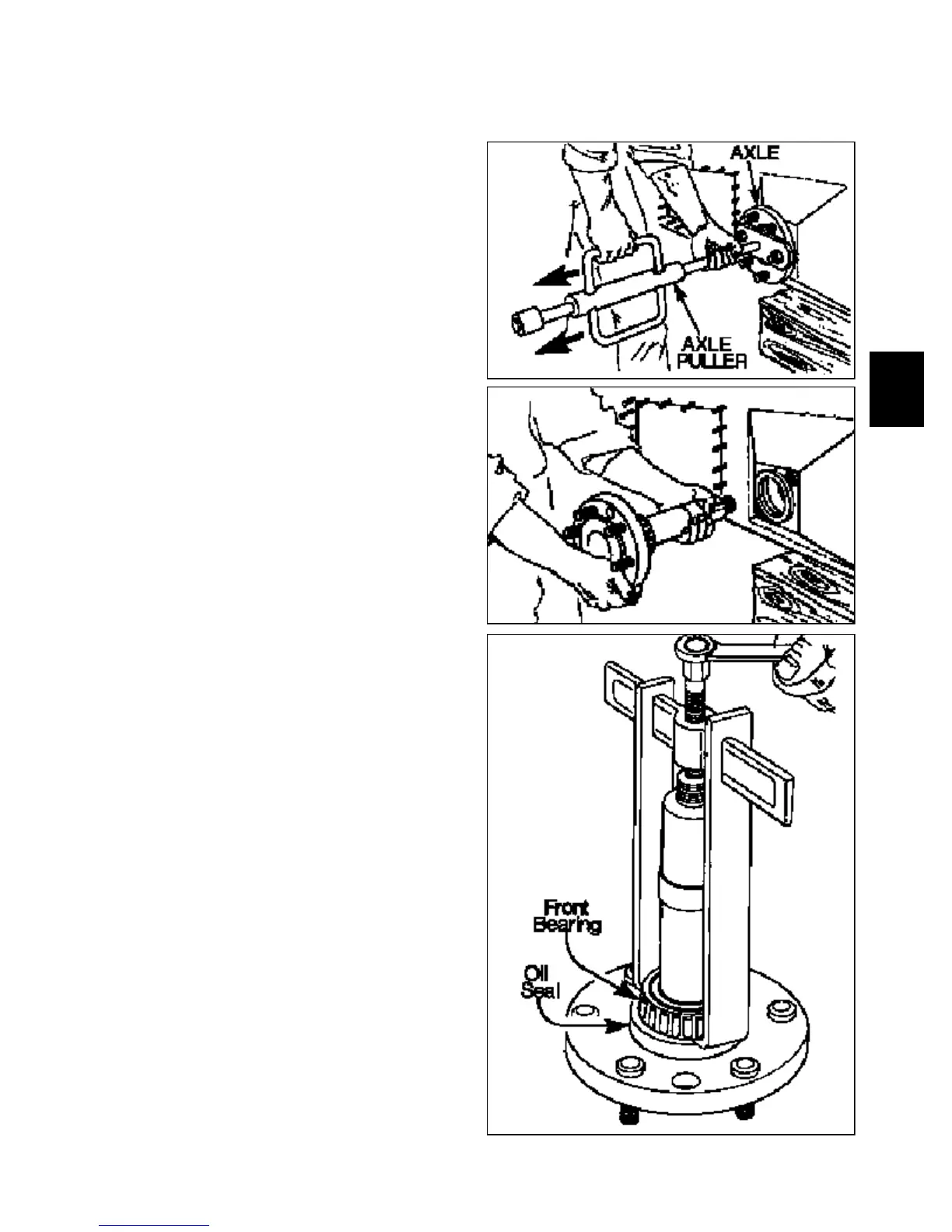

18 Using a bearing puller, remove the bearing still

pressed in place on the axle. (fig. C221)

19 Remove and discard the axle oil seal.

1 Inspect the seal surface area for scaring, pitting or

nicks. Minor scratches may be removed using fine emery

cloth. Replace the axle if worn excessively.

2 Inspect the axle threads for damage. Replace axle if

the threads are non serviceable.

3 Inspect the axle keys for wear Replace as required.

4 Inspect the key way slots for wear. Replace the axle

and keys if the keys do not fit tightly into the key ways.

5 Replace any axle studs as required.

6 Inspect the axle sprocket for abnormal tooth wear

and the fit of the axle key in the sprocket key ways.

Replace the sprocket if necessary.

7 Inspect the bearing races in the final drive housing.

Replace them if necessary using a brass drift punch and

hammer. Cooling the races in a freezer will aid in easing

this procedure.

8 Replace the bearings if new races are installed or if

they are pitted or damaged.

Inspection

Loading...

Loading...