C4352

C4353

C4354

Disassembly 137/153 (cont’d)

1-10

GEAR PUMP 1.2

6. Procedure

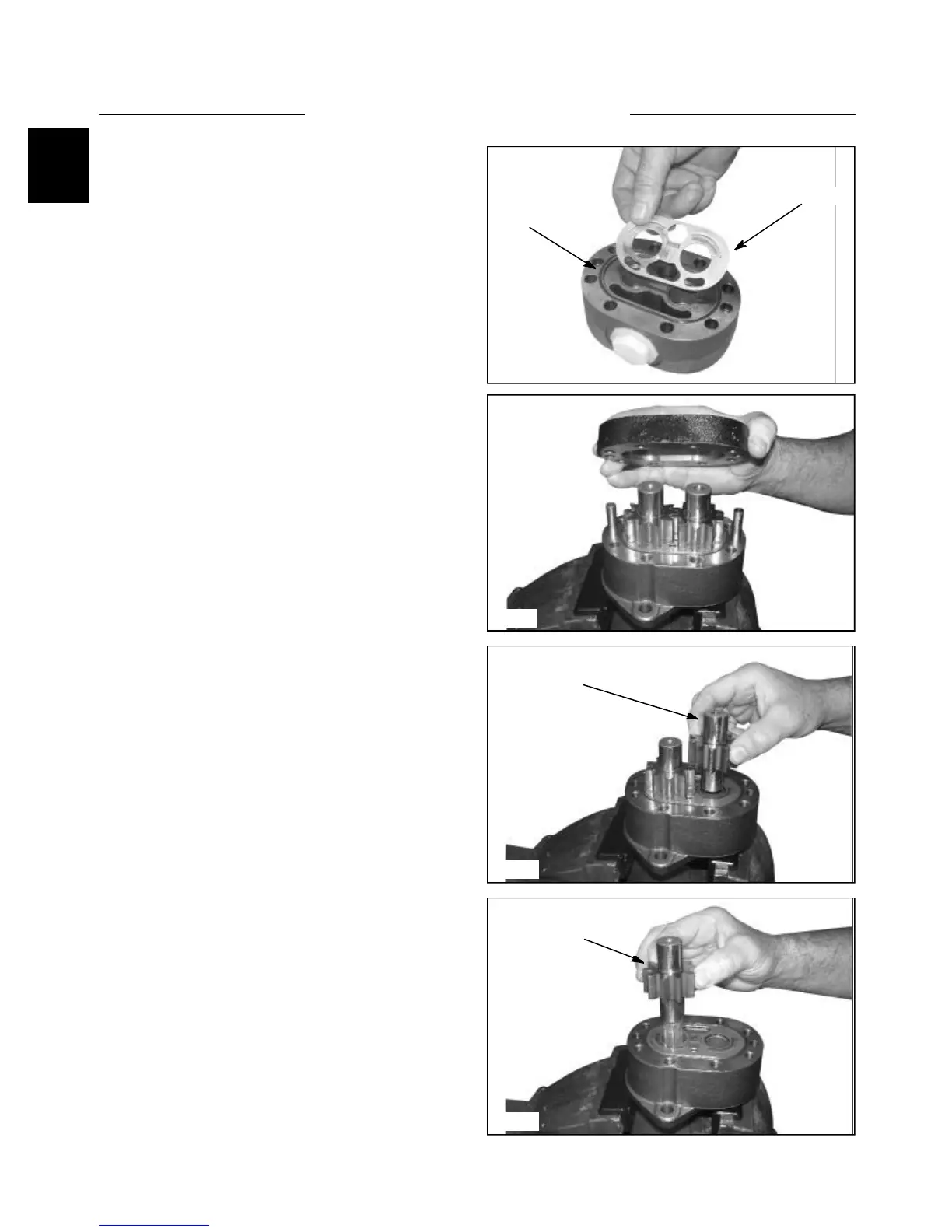

4. Place the cover assembly on the work bench

(fig. C4352). Inspect the wear plate for evidence of

extrusion or marks caused by overheating. Replace

if necessary. Remove the wear plate and seal ring on

the cover assembly. Do not use tools with sharp

edges to remove the seal, as damage to the housing

may result.

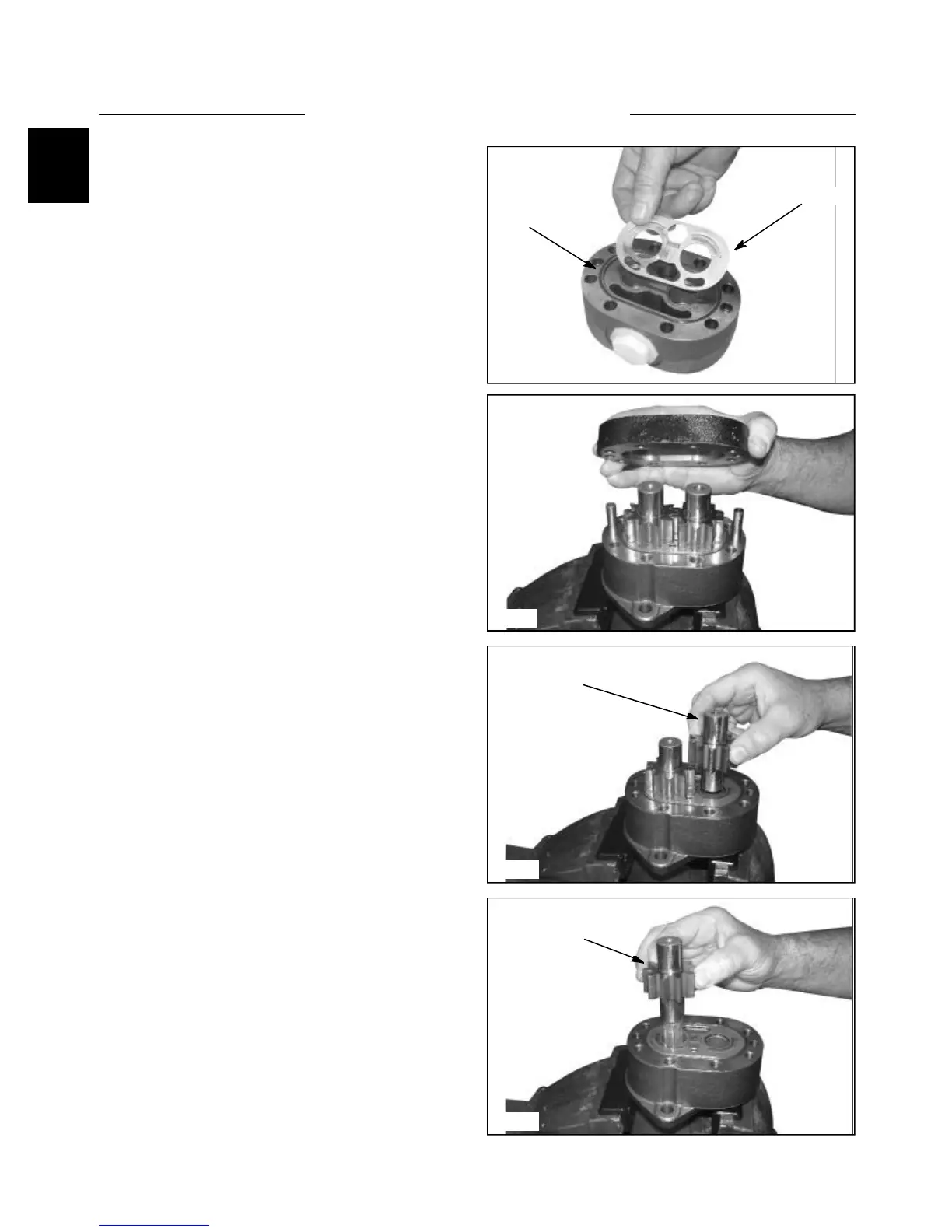

5. While disassembling the unit, you need to mark

the relative positions of the gear mesh (drive gear

tooth and idler gear tooth) and the body so they can

be reassembled in the same position. Carefully

remove the gear plate (fig. C4353). Remove the

dowel pins and place in the gear plate.

6. Remove the idler shaft and drive shaft from it’s

bearing bore. Inspect the journals and the flat faces

top and bottom of the gears. Ensure these surfaces

are free from burrs or scratches. If scratches are

found, clean them with a flat stone and/or a very fine

emery cloth. Rewash the gears with light oil after

this operation.

Wear Plate

Seal Ring

Idler Shaft

Drive Shaft

C4355

Loading...

Loading...