32

4. Engine Compartment

The engine compartment is completely enclosed for

component protection and lockable to discourage

vandalism. For servicing the rear door swings open and

the engine cover hinges up.

To open; raise the door lock handle up over the lock plate;

pull outward releasing the door catch and swing the door

open (Fig. 4.2E). Lower the engine cover before closing

the rear door. Figure 4.2F shows the engine compartment.

4. 3 DAILY SERVICE CHECK

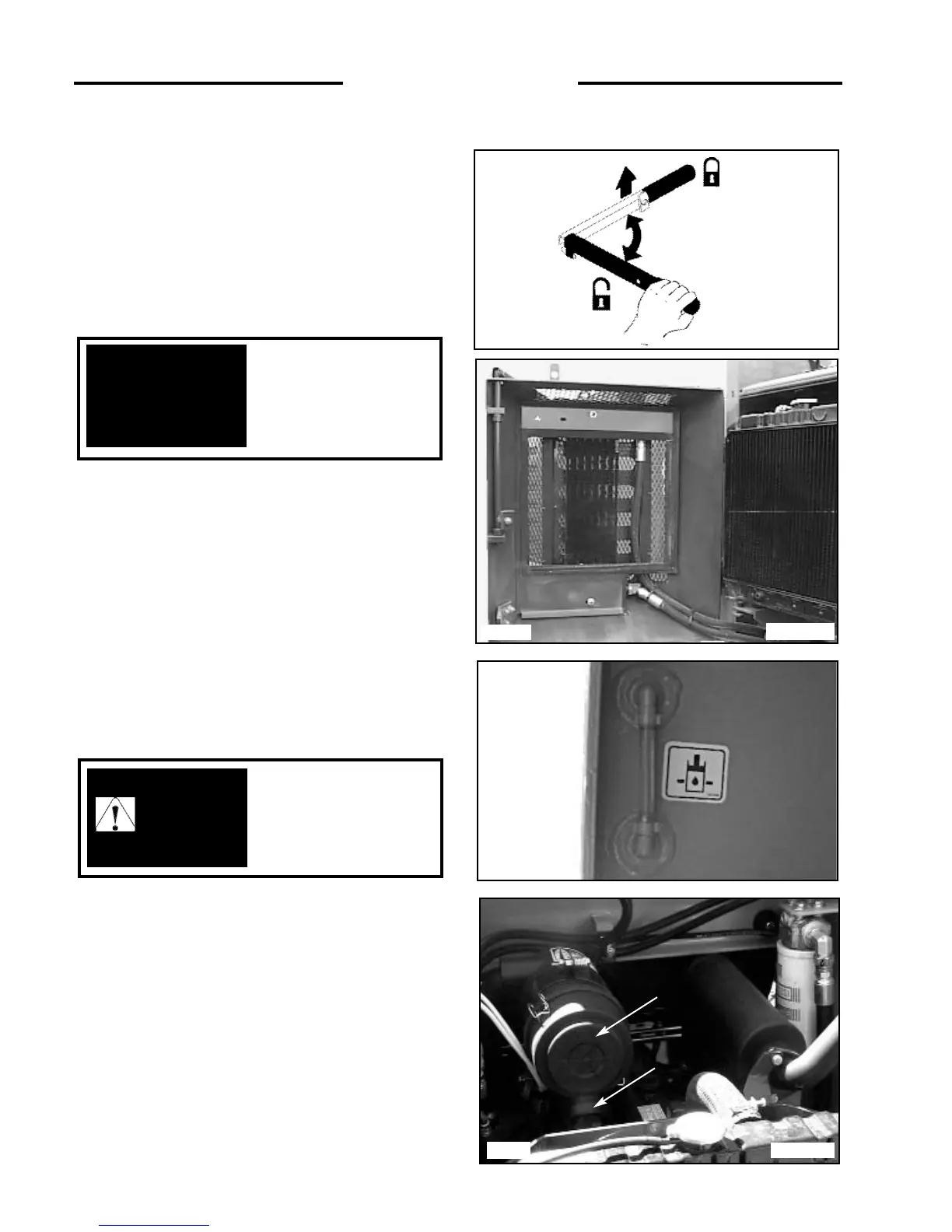

1. Hydraulic Oil Level

Check the oil level with the machine on a level surface

with the lift arms down and the attachment grounded.

Open the rear door and check the oil level sight glass (Fig.

4.3A). If oil is apparent the oil level is satisfactory.

If necessary to add oil, remove the reservoir cap located

at the top of the oil reservoir and add oil until oil appears

in the oil level sight glass.

Use a good quality 10W30 oil which meets the API

classification SH only.

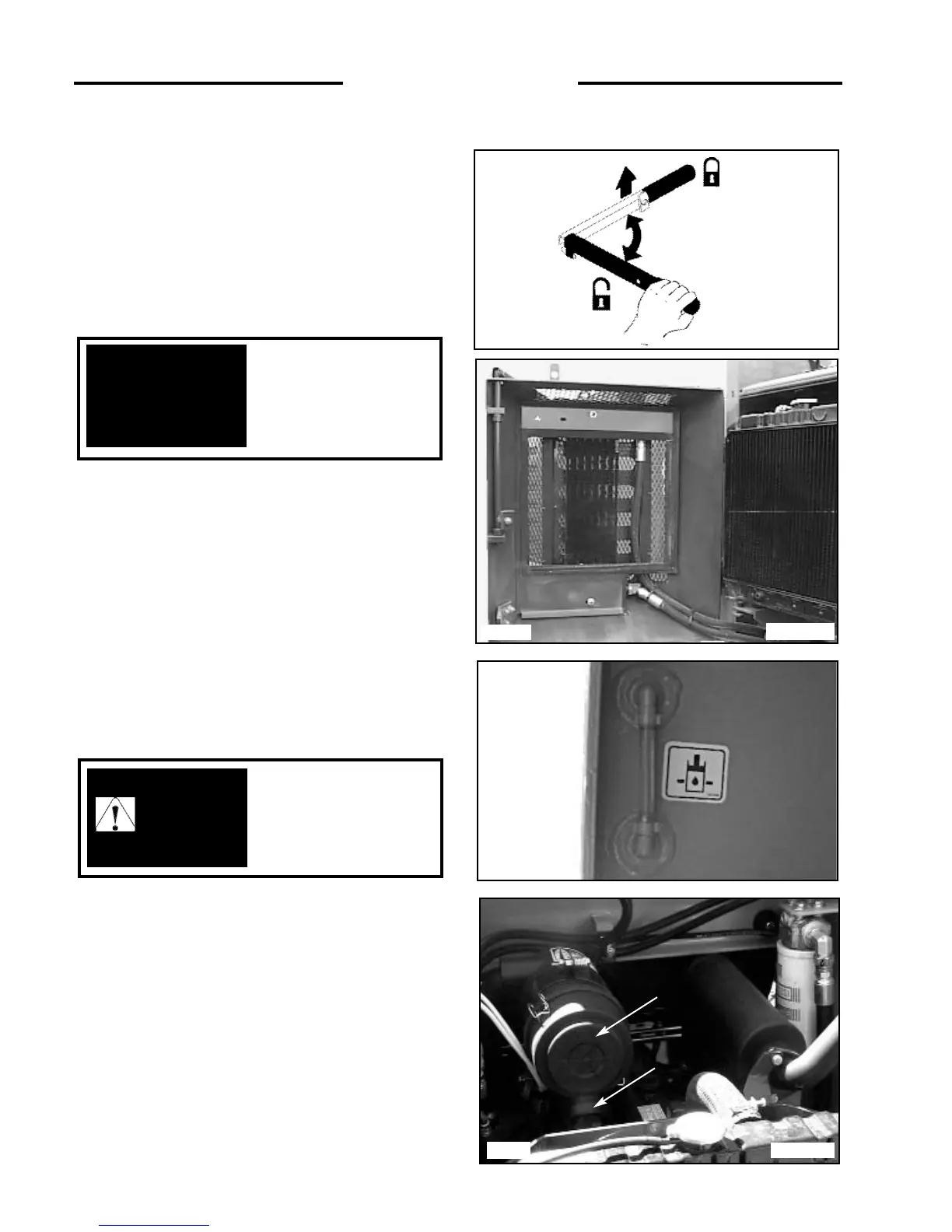

2. Air Cleaner

The loader is equipped with an air cleaner restriction

warning lamp. Should this lamp illuminate, shut off the

engine and determine cause. Possibly a plugged air filter.

Figure 4.3B shows the air cleaner.

Check that all hose clamps are tight and the hose is

undamaged. Check the vacuator valve for damage (Fig

4.3B).

See Section 4.9 for Air Cleaner Maintenance.

Fig. 4.2F

C1866

Keep the rear door

closed except for

servicing. Make sure the

door is closed and

latched before operating

the loader.

IMPORTANT

4. MAINTENANCE

C644

Fig. 4.3A

C674

Fig. 4.2E

WARNING

To avoid personal injury:

Stop, Cool and Clean the

engine of flammable

materials before

servicing. Never service

or adjust machine with

engine running.

Fig. 4.3B

C1237

Air Cleaner

Vacuator Valve

Loading...

Loading...