33

3. Tires and Wheel Nuts

Inspect tires for wear or damage. Check and inflate tires to

correct pressure:

10.00 x 16.5 ...........40 - 45 PSI (276 - 310 kPa)

Tires can be inflated to 50 PSI (345 kPa) when operating

on hard, flat surfaces.

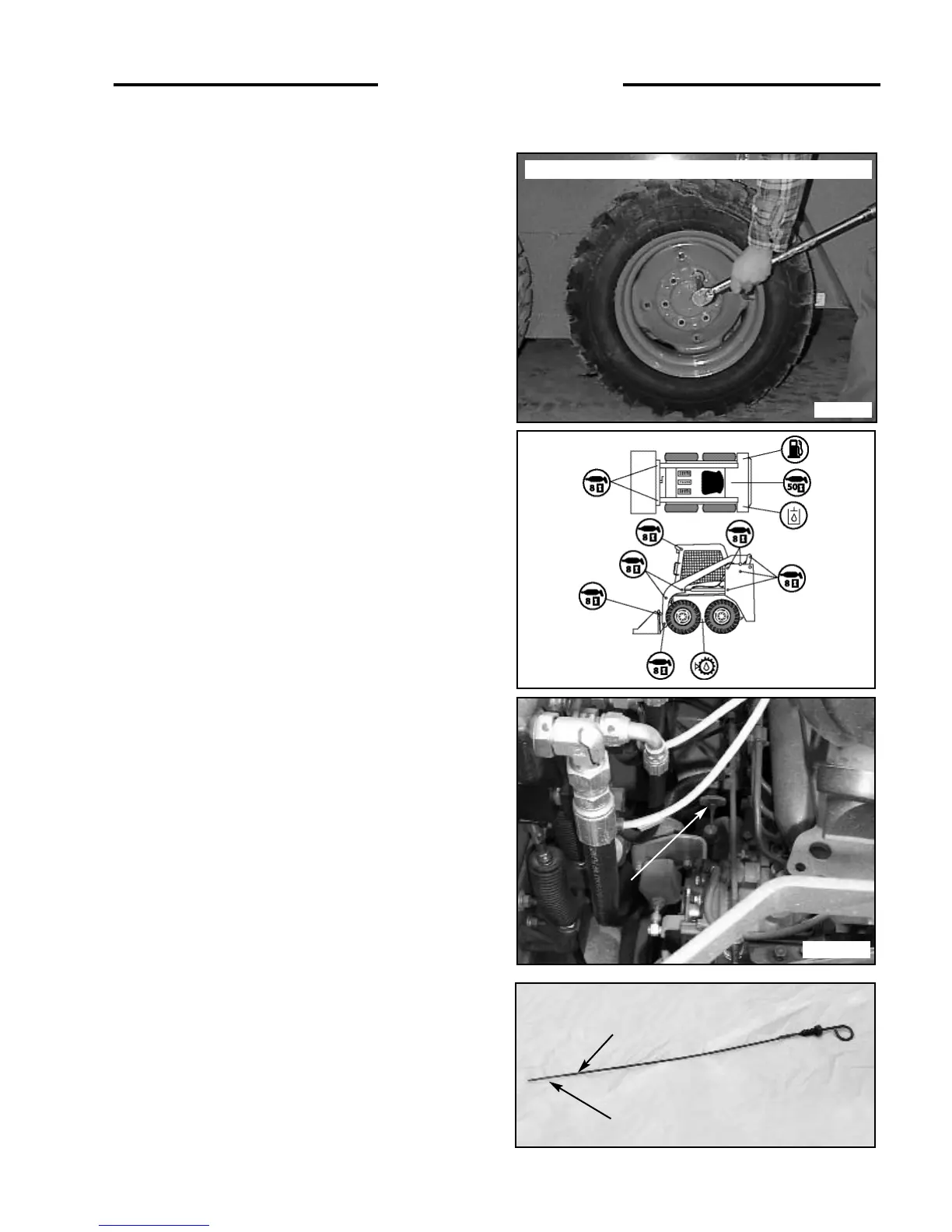

To prevent shearing of the wheel studs and rim damage

check wheel nuts for proper torque 100 -110 lbs. ft. (136 -

149 Nm) daily (Fig. 4.3C). After changing a rim, Check

wheel nuts hourly, until the reading stabilizes.

4. Safety Equipment

Check all safety equipment for proper operation and

condition - seat belt, lift arm supports, seat bar, steering

neutral lock, parking brake, quick tach lock, shields,

safety treads and lift arm lock down. Lubricate all

linkages, springs and pivot points with a silicone based

lubricant. Repair or replace if necessary.

5. Decals

Check the condition of all safety and instruction decals.

Replace any damaged or missing decals. Refer to Section

5.3 for decal description and locations.

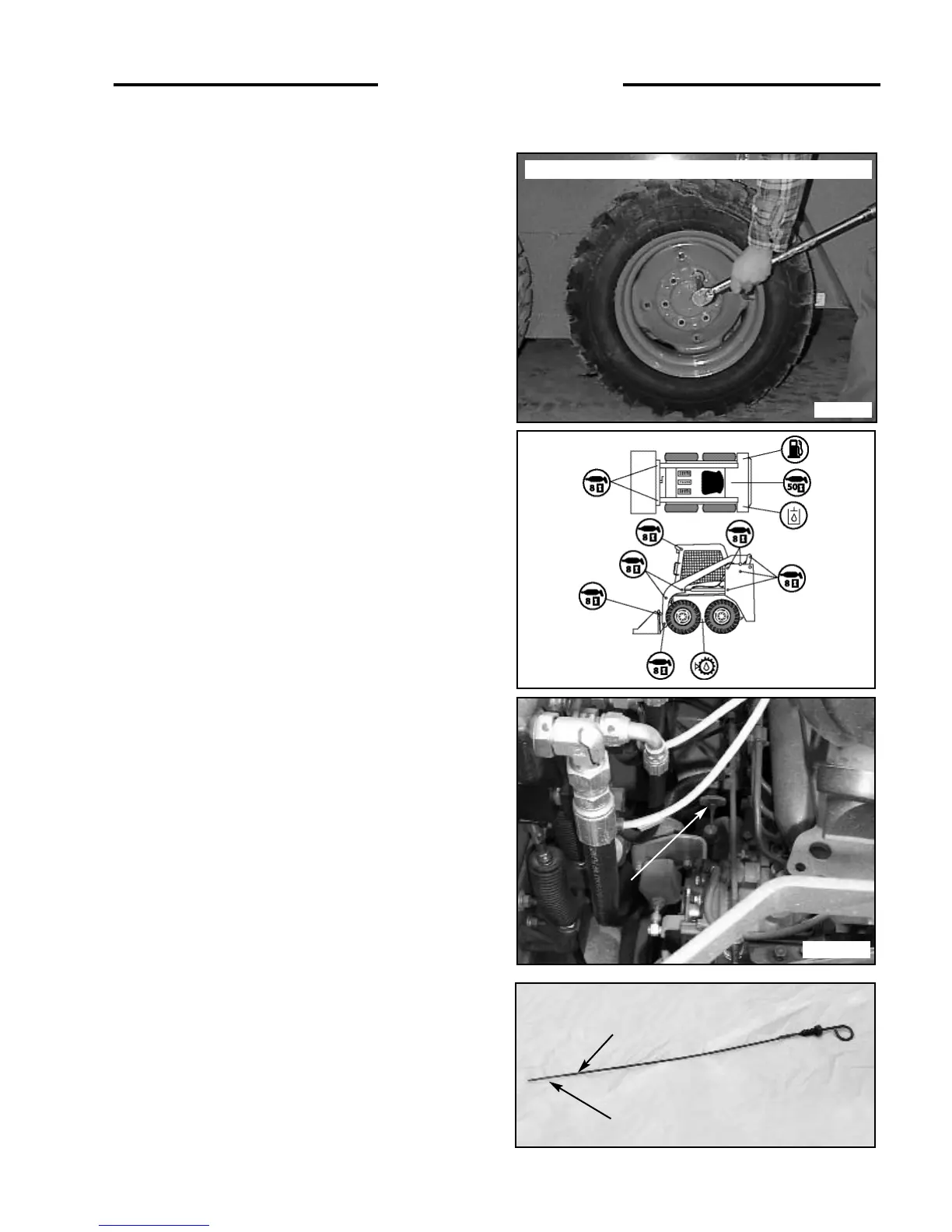

6. Lubrication

There are sixteen (16) grease fittings located in the loader

that require lubrication every eight hours. Lubricate with

a good quality multi-purpose lithium based grease. Apply

grease until excess shows. Refer to the service schedule

for complete service details. (See Fig. 4.3D). The sixteen

(16) lubrication points are:

Rear Lift Arm Pivots (2)

Lift Cylinder Bushings (4)

Bucket Cylinder Bushings (4)

Lift Arm Supports (2)

Quick Tach Pivot and Lock Pins (4)

7. Engine Oil Level

Check the oil before engine start up. If the engine has been

running let it cool for at least 5 minutes to allow the oil to

drain back to the oil pan.

To check the oil level, check with the loader on level

ground, open the rear door and remove the dipstick (Fig.

4.3E).

Keep the oil level between the full and low mark on the

dipstick (Fig. 4.3F). Do not fill above the full mark. Use

API Classification CF oil.

4. MAINTENANCE

C3956

Fig. 4.3D

Torque Wheel Nuts 100 - 110 lbs. ft. (136 - 149 Nm)

Fig. 4.3C

C3415

Fig. 4.3E

Dipstick

Location

C3414

Fig. 4.3F

FULL

LOW

Loading...

Loading...