The engine management unit controls the feed rate of the material going into the chipping chamber. If

the engine speed is below the predetermined level, the engine management unit will not allow the feed

rollers to work in the forward “infeed” direction, until the rotor speed rises above the predetermined

level. At this point, the feed rollers will start turning without warning. The reverse function will work at

any engine speed.

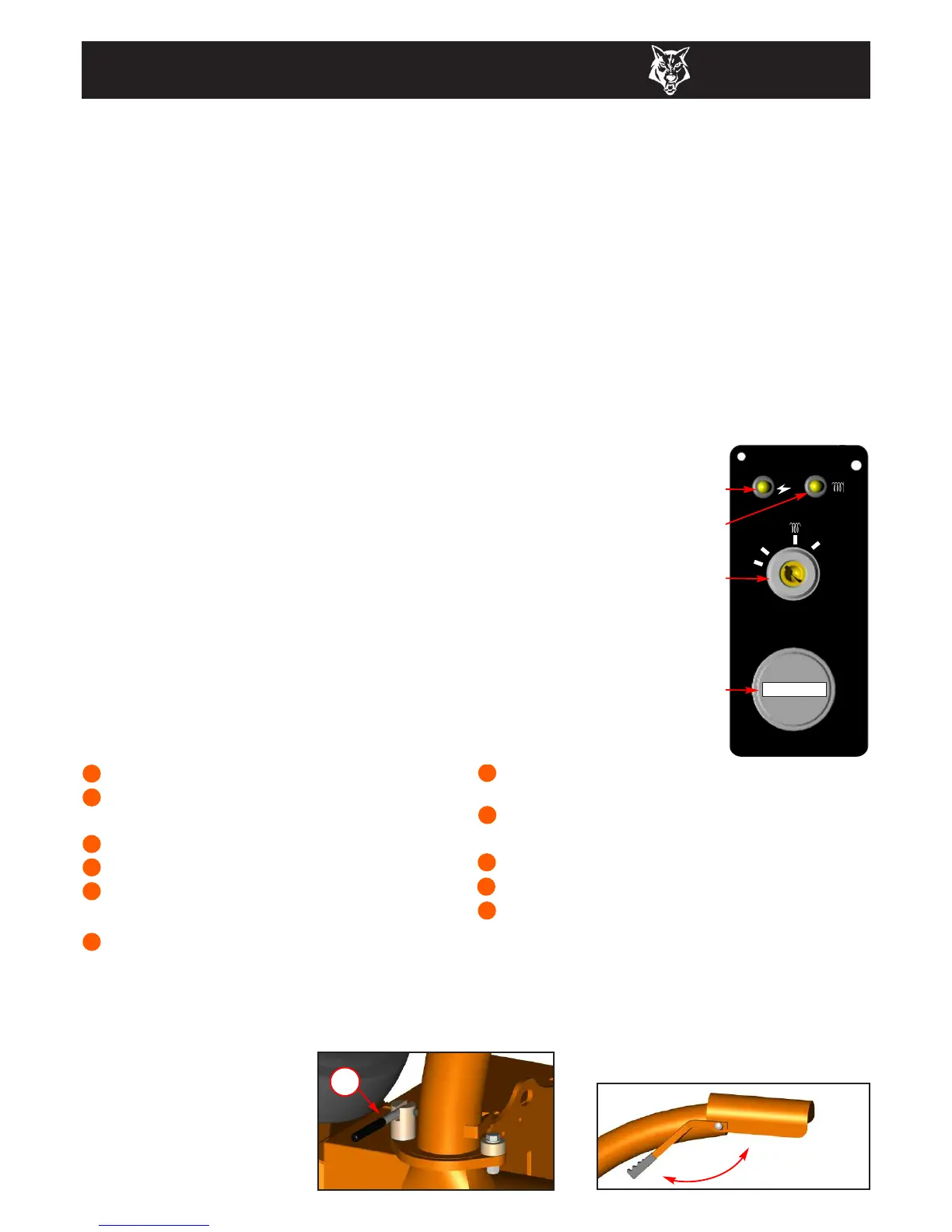

The engine controls are in two locations. The engine ignition is on the

control panel in the centre of the machine, and the throttle lever is on the

bonnet (see parts locator on pg. 3).

This can be viewed through the wall of the tank.

Maximum and minimum marks are provided.

LOCATE the machine on firm level ground.

CHECK machine is well supported and

cannot move.

CHECK jack stand is lowered and secure.

CHECK all guards are fitted and secure.

CHECK the discharge unit is in place and

fastened securely.

CHECK discharge tube is pointing in a safe

direction.

CHECK the feed funnel to ensure no objects

are inside.

CHECK feed tray is in up position - to prevent

people reaching rollers.

CHECK controls as described on page 12.

CHECK (visually) for fluid leaks.

CHECK fuel and hydraulic oil levels.

For parts location see diagrams on pages 4 & 5.

AUTO CONTROLS

EMERGENCY STOPPING

ENGINE CONTROLS

HYDRAULIC OIL LEVEL INDICATOR

FUEL LEVEL INDICATOR

TIMBERWOLF

TW 190TDHB

11

OPERATING INSTRUCTIONS

0

1

2

POWER

ON LED

HEATER

ON LED

POWER

ON /OFF

& START

HOURS

COUNTER

1462975

There are two ways of stopping the TW 190TDHB (Turbo) chipper in the event of an emergency.

STOPPING THE ROLLERS

-Activating the red safety bar will stop the rollers immediately. To restart the rollers, just push the green

forward button or blue reverse button.

-Pushing the red Emergency button on the roller control box will also stop the rollers immediately.

The button will stay in the “pushed in” position, and will require resetting (pulling out) before being

able to restart the roller functions.

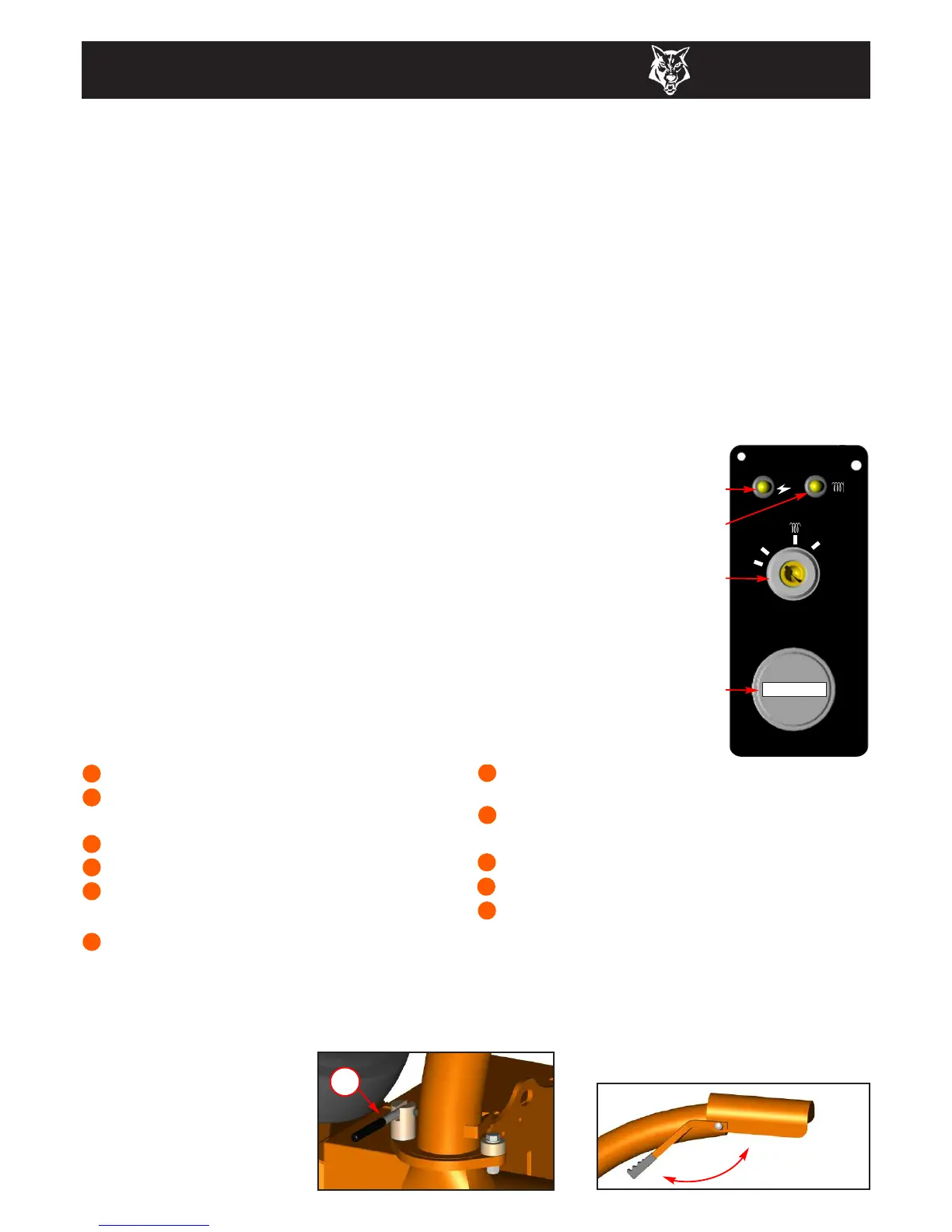

ROTATION

1. Slacken nut using

integral handle.

2. Rotate tube.

3. Retighten nut.

1

The fuel level can be seen through the wall of the fuel tank.

DISCHARGE CONTROLS

DAILY CHECKS BEFORE STARTING

Controlling the discharge is an essential part of safe working.

BUCKET ANGLE

4. Adjust the bucket to the desired

angle using the handle provided.

Loading...

Loading...