1-4

Service Information

4st 4/5/6 2011

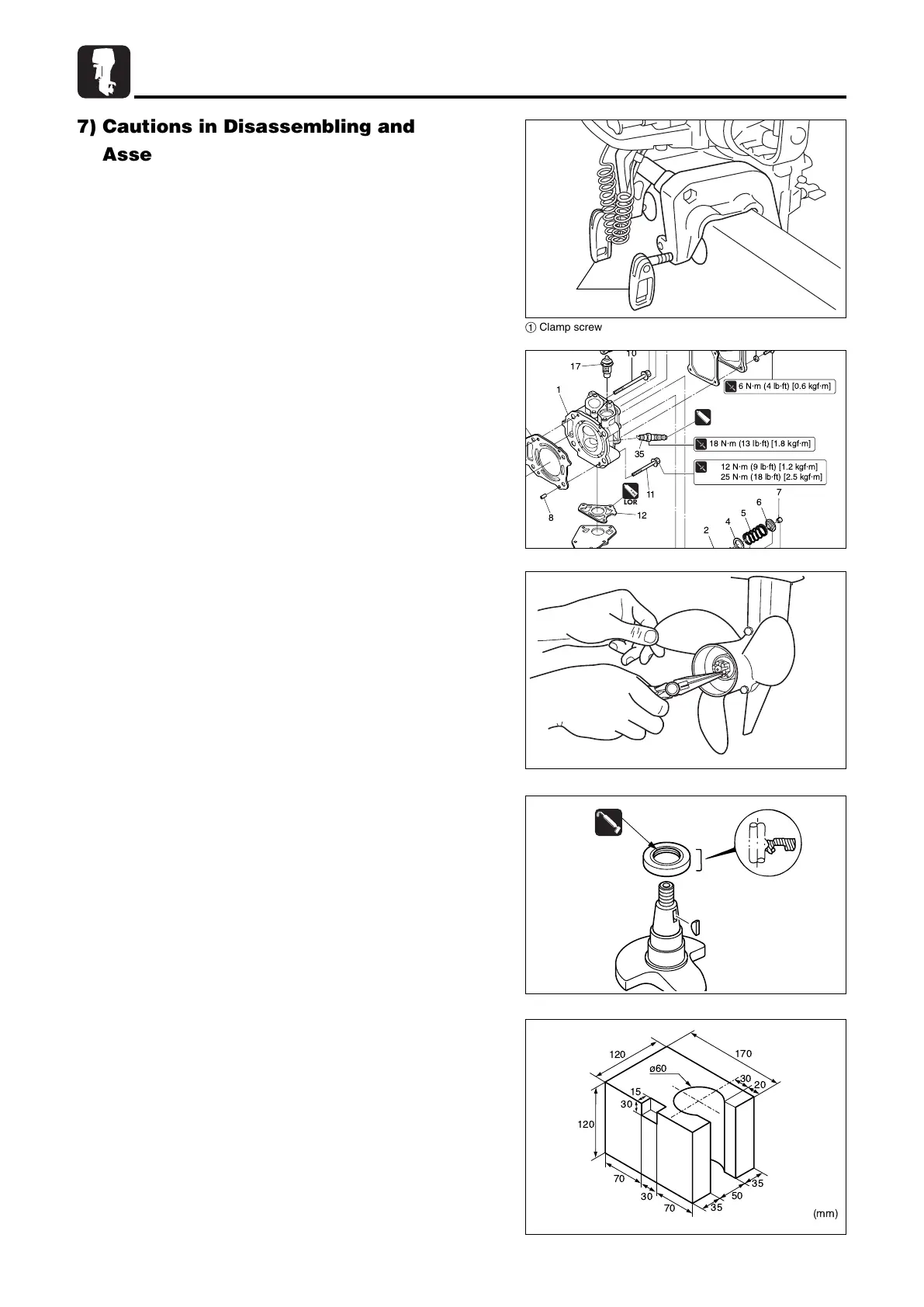

PowerUnitWorkTable

(mm)

¿60

170

20

70

70

120

120

15

30

30

30

50

35

35

7) Cautions in Disassembling and

Assembling Components

(1) Secure outboard motor to dedicated stand firmly.

(2) Take special care not to scratch painted surfaces or mating

surfaces of cylinder and crankcase.

(3) Replace parts such as packings, gaskets, O rings, oil seals,

spring pins or split pins with new ones after they are

removed. Replace deformed snap rings with new ones.

(4) When replacing parts, be sure to use genuine parts. For

fluids such as gear oil, use genuine product.

(5) Be sure to use special tools that are specified, and perform

the work properly.

(6) When reassembling parts, use their mating marks. For parts

without mating marks, simple marking makes reassembling

easier. Use applicable parts list for reference.

(7) Clean individual parts that have been removed, and check

their condition.

(8) When assembling, be careful of the fit, repair limits, air-

tightness, clogging of oil holes for oil feeding or greasing,

packings, wirings, pipings and other detailed parts. For the

components that use many bolts and nuts such as cylinder

head or crank case, tighten the fasteners in the order shown

by the numbers to prevent uneven tightening. If the numbers

are not shown, tighten the fastners in diagonal or clockwise

order from inner ones to outer ones evenly to specified

torque. In either case, tighten the fastners to the specified

torque in two or three steps. (Reverse the order when

disassembling.)

(9) When installing bearings, face the flat (numbered) side to the

special assembling tool.

(10) When installing oil seals, be careful not to scratch the

surface of the lip that contacts with the shaft, and install them

in correct orientation. Apply recommended grease to the lip

before installation.

(11) When applying liquid sealant, take care to use sparingly.

Excessive application may be oozed out, adversely affecting

interior of the crankcase. Use adhesive after thoroughly

reading the instructions.

(12) When servicing power unit, use of wooden work board

makes the work easier.

SOC

OIL-COMP.

GM

SOC

SOC

1

2

LOR

Liquid O-Ring

LOR

1 Clamp screw

MFS4-5-6Ech01110422.qxd 11.4.22 5:41 PM ページ4

Loading...

Loading...