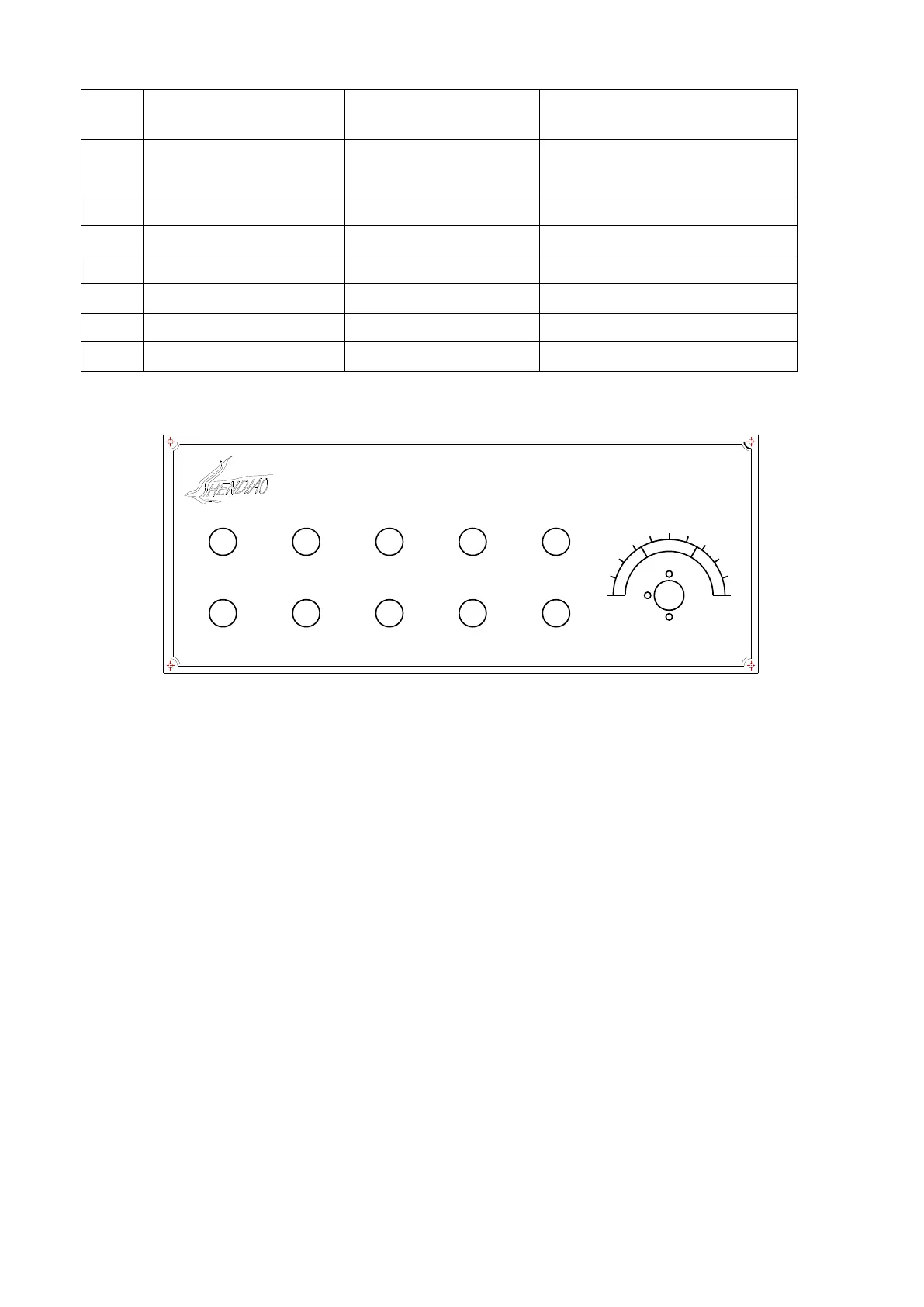

Ⅷ Operation system

Operation panel

1.Control panel composition and function

(1) Press the "EMERGENCY STOP" buttons, cutting off power supply, rotate

clockwise direction, mushroom handle outward increased, connect control power; If

the pressure pushed inward, mushrooms handle inward compression, disconnect

power control.

(2) Press the "RUNNING" button, the main motor running take the saw blade rotary,

and pumps work, to achieve the cooling cycle. If "Clamp up" button not pressed, the

control can only done by man. Press the "stop" button to stop the mainframe and

pump.

(3) Press “OIL PUMP” button , Oil Pump and Hydraulic System start to work.

Loading...

Loading...