(10). Tighten the left and right adjustment bolts to compress the alloy block and saw

blade.

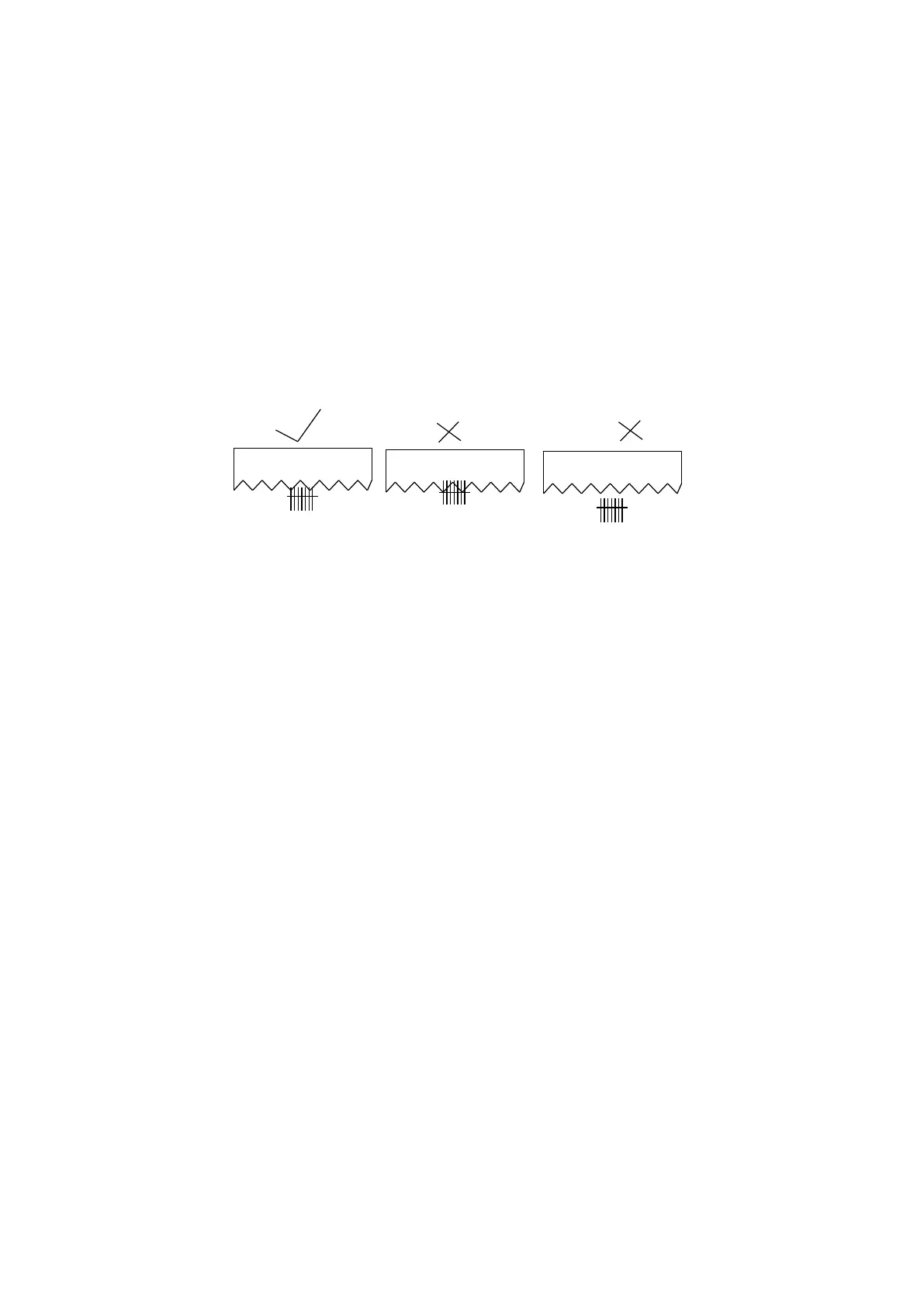

(11). Adjust the location of copper wire brush to make it contact with saw tooth, see

the position in Chart 10. When the copper wire brushes worn, adjust any time and

finally fastening bolts.

Figure 10

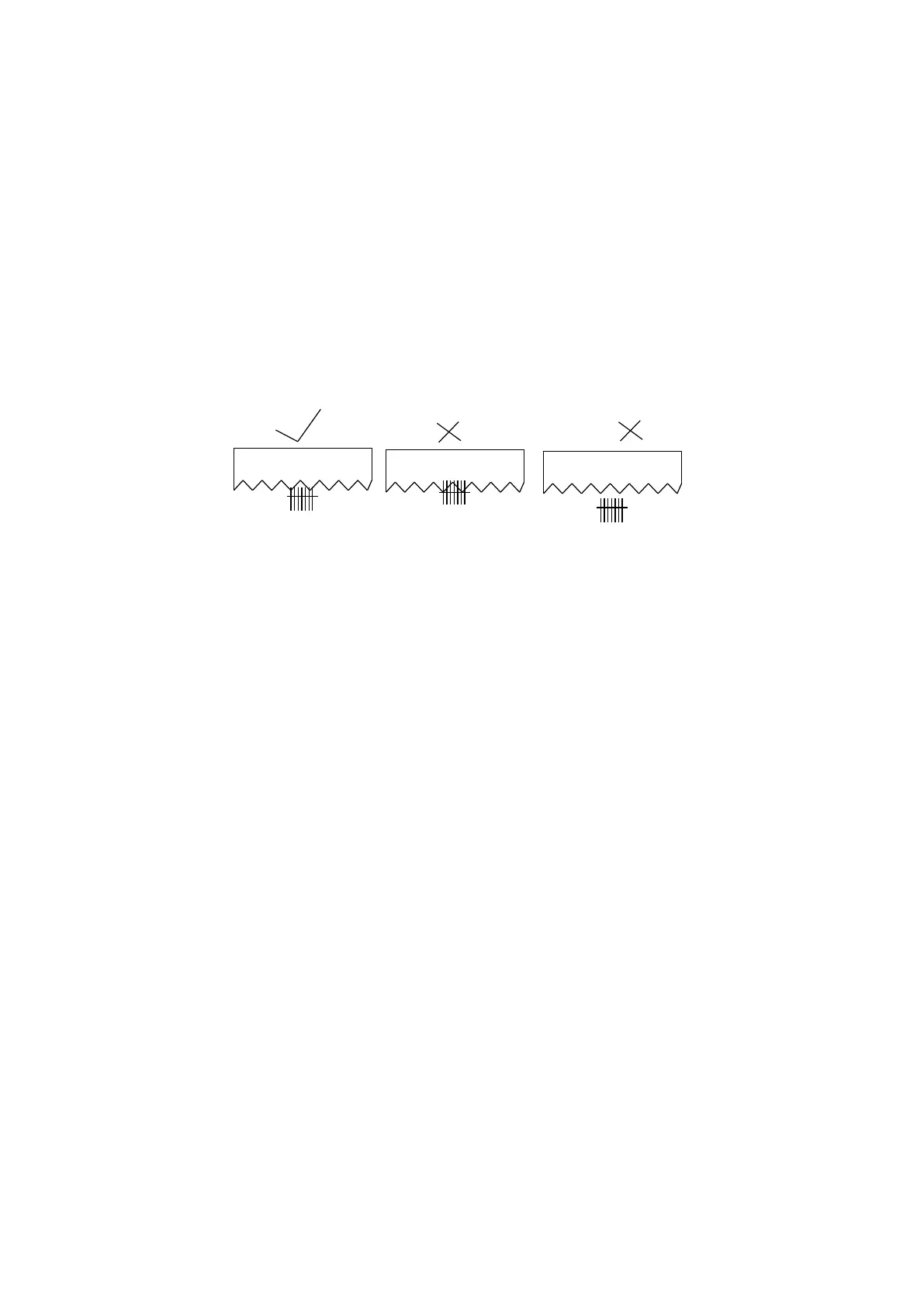

(12).The Deviation adjustment of Idler Band wheel. The axle centerline of Idler Band

wheel is not vertical to saw blade movement direction. When the Saw Blade is not in

tension, requires the direction of axle center line of Idler Band wheel,which is

perpendicular to the movement of the saw blade, oblique to the left 0.5 ° -0.8 °,

see figure 12. This can avoid the saw blade down from the outer edge of Idler Band

wheel, when the saw blade is running, which may lead to saw swap. If the swap

occurred, must adjust the deviation of the Idler Band wheel. Adjusted as follows:

First, take the plane of Drive Band wheel as reference, adjust the first two screws of

Tension Block, which is behind the Idler Band wheel bean, see figure 12. Adjust the

parallelism of Drive Band wheel and Idler Band wheel. (Way of check: put two

plywood with the size of 35 cm x 35 cm on the top of two wheels, check them if

parallelism), then adjust another screw, see figure 13. Do the declination adjustment

Loading...

Loading...