28

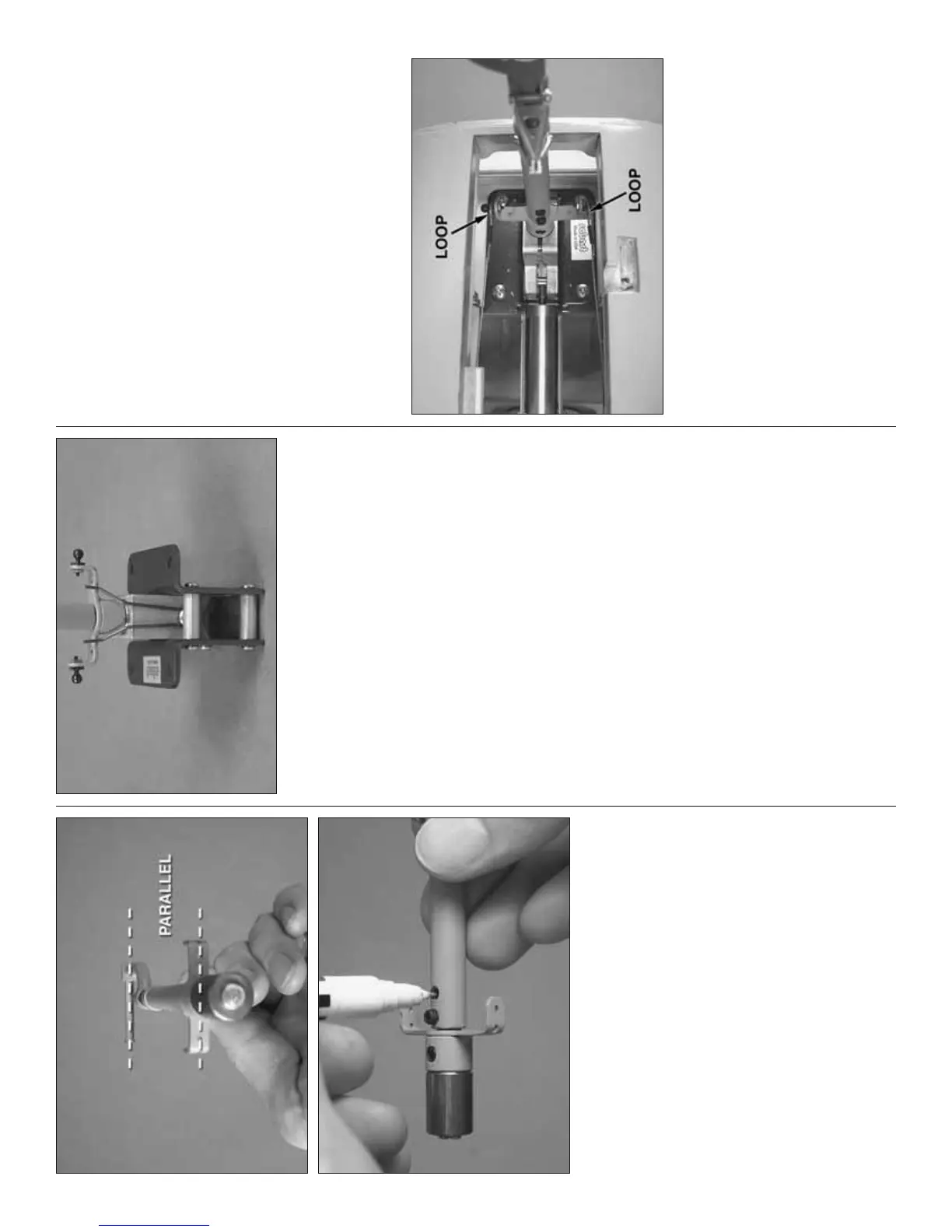

❏ R10. With the strut assembly back together but

still out of the retract unit, align the steering arm with

the axle and hold it in position with the top set screw.

Remove the bottom set screw and use a fi ne-point

felt-tip pen to mark the location of the hole. Grind

another fl at spot at the mark. Reassemble the unit

making sure the steering arm has remained parallel

with the axle. Adjust the fl at spot if necessary. When

assembling the unit for the fi nal time, use threadlocker

on the threads of all the set screws.

❏ R11. Reassemble the strut to the retract unit.

❏ R12. Mount an 0-80 ball link to both steering arms

with a drop of threadlocker and 0-80 nuts.

❏ R13. Connect 18" [480mm] of air line to each

fi tting on the air cylinder on the nose gear. Do not

connect the short pieces of tubing from your can of

compressed air to the air lines until step R17.

❏ R14. Holding the retract unit in your hand, retract

the gear (put the gear up). Guide the air line attached

to the side of the air cylinder through the small hole

in former F2 in the fuselage. Then, place the retract

in the mounting rails in the fuselage.

NOTE: The rest of the nose gear mounting

instructions are for both fi xed gear and

retractable gear even though retracts are shown.

Where applicable, separate notes for each setup

are provided.

❏ 15. Place the nose gear in the mounting rails in the

fuselage. Mark the locations of the screw mounting

holes onto the wood rails (for retractable nose gear

this will be easier to do if the gear is retracted). If

installing fi xed gear, temporarily remove the nose

gear. Drill four 7/64" [2.8mm] holes through the rails

at each mark. Mount the gear to the rails with four #6

x 1/2" [13mm] Phillips screws.

❏ 16. Mount the nose wheel to the gear. If using

retracts, cut the axle to the correct length and grind

or fi le a fl at spot for the set screw. If using fi xed gear

mount the nose wheel with two collars and 6-32 set

screws—and use threadlocker on all screws.

❏ R17. If mounting retractable nose gear, operate the

gear by hand and with your can of compressed air.

Make certain the gear operates freely, does not hit the

edges of the opening and is able to lock in both the up

and down positions. Make any adjustments necessary.

❏ 18. Connect the nose steering servo to your

radio and turn the system on. Make sure the servo

arm is centered. Note: A good way to set up the

nose steering is to connect the servo to an unused,

available channel in your receiver. Use the mixing in

your transmitter to electronically mix the nose steering

servo to the rudder, but assign a dial or lever on the

transmitter to the nose steering servo. At the fl ying

fi eld the dial or lever can be used to trim the nose

wheel so the model will roll straight down the runway.

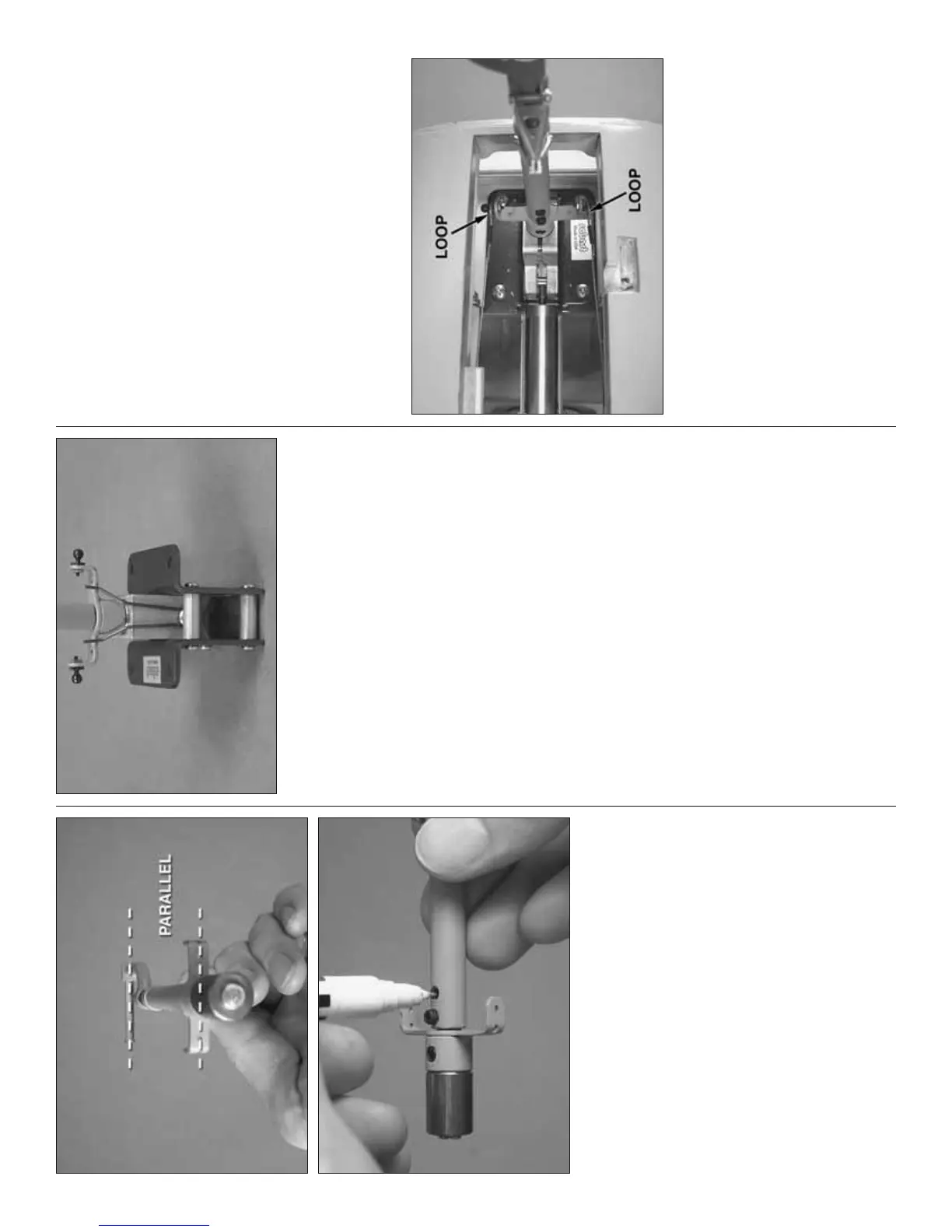

❏ 19. With the radio system on (so the nose steering

servo arm cannot move), loop the ends of the steering

cables over the ball links on the nose gear and secure

with another swage on each cable. The loops in each

cable should be large enough to slip over the ball

link, but small enough so that they won’t come off on

their own. Adjust the clevises on the servo end of the

cables to center the nose wheel.

Loading...

Loading...