33

switch, guide the wire through the mounting hole in

the fuselage, and THEN connect the charging plug to

the receptacle mount. Mount the switch and charge

jack to the fuselage.

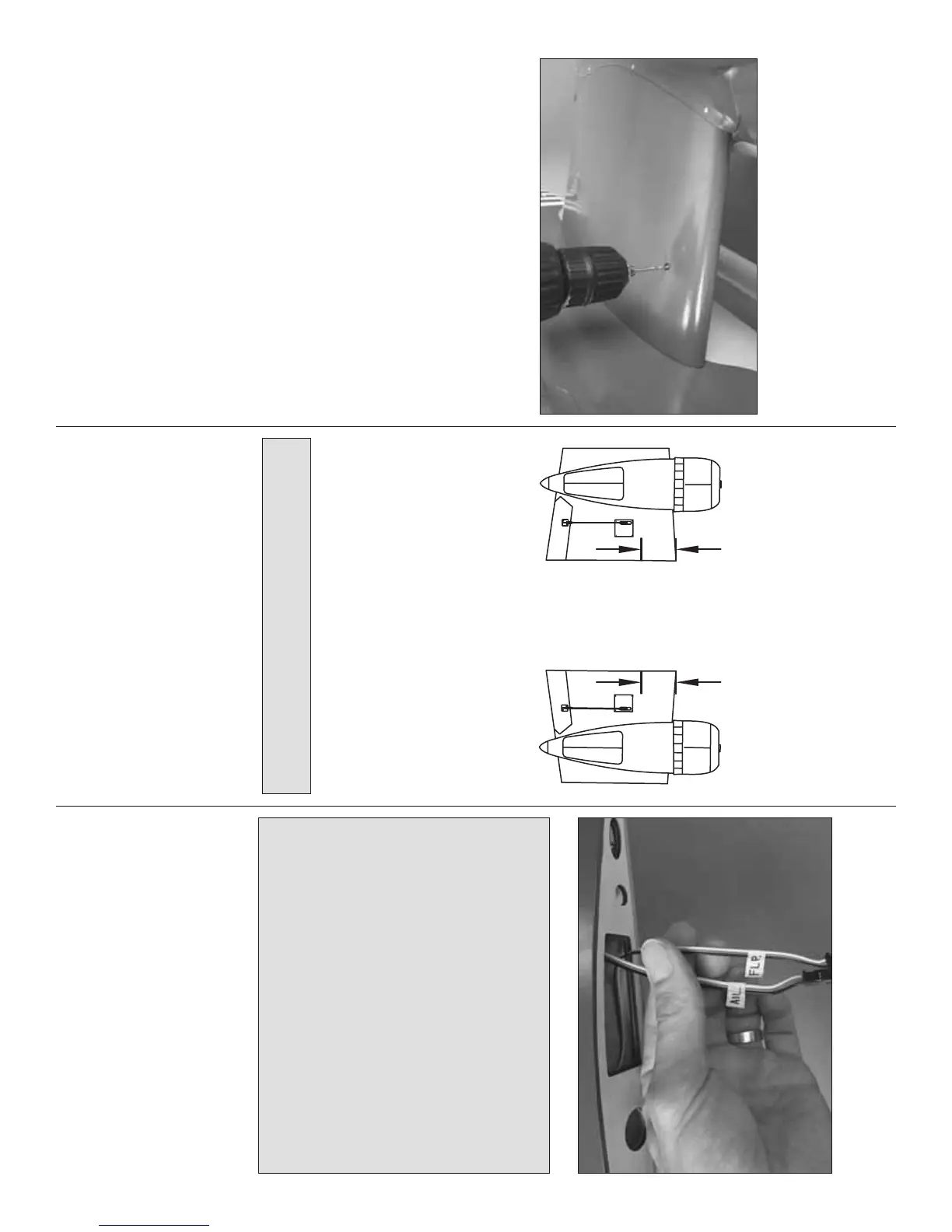

❏ 3. Refer to the wiring diagrams in the back of the

manual for the servo extensions and Y-harnesses

used. Install and connect the wires as shown. Where

appropriate, secure connections between wires with

heat shrink tubing.

Throttle hookup: The wiring diagram for

connecting the throttle servos shows each servo

connected to separate channels in the receiver. They

are linked electronically through the transmitter,

but your receiver must also have an available

channel for this mix. For our Futaba radio we

connected one engine to channel 3 and the other

engine to channel 8 (Auxiliary 2). Depending on the

position of the assigned mixing switch, the throttles

can be operated separately (for synchronization

tuning and starting) or together with the throttle stick

during fl ight. However, if you do not have enough

available channels to link the throttles through the

transmitter, they could be linked with a Y-Harness

and connected to the same channel.

❏ 4. Mark the ends of all the servo wires that are

to be connected and removed during assembly and

disassembly at the fi eld with masking tape and a pen.

❏ 5. Guide the receiver antenna down through the

antenna tube in the fuselage.

❏ 6. Temporarily attach the inboard and outboard

wing panels and tail to the fuselage and connect all

the servo wires. Turn on the radio and make sure

everything operates correctly. Make any adjustments

necessary. Now would also be a good time to connect

the air lines, pressurize the system and operate the

retractable landing gear as well.

NOTE: The receiver battery pack will be mounted

after the nose-gunner cabin has been completed.

MOUNT THE INBOARD WING PANELS

We’ve already had the wings on and off the fuselage

a couple of times, but now it’s time to mount them

“for real.”

One end of the forward and aft aluminum wing tubes

is already drilled and tapped for 4-40 screws, but the

other end has to be drilled and tapped too.

The balance point is 5" [127mm]

from the leading edge of the wing

where it contacts the fuselage.

5"

[127mm]

❏ 1. If you will not be balancing the model with a

Great Planes C.G. Machine, you will need to mark the

balance point on the bottom of the wing so you will

know where to lift the model when it’s time to check

the C.G. later. Now would be a good time to do this.

Use a fi ne-point felt-tip pen to mark the balance point

on the bottom of both inboard wing panels where they

meet the fuselage 5" [127mm] back from the leading

edge. There will be more information on C.G. and

balancing the model later after assembly has been

completed, but it’s a good idea to mark the balance

point now (if you won’t be using a C.G. Machine).

❏ 2. Fit either inboard wing panel to the fuselage

with the 30 x 440mm center main wing tube and both

10 x 305mm forward and aft main wing tubes. The

ends of the smaller tubes that have the threaded

holes should be inside the wing you are attaching to

the fuselage fi rst.

❏ 3. Turn and position the forward and aft tubes so the

threaded holes align with the holes in the wing panel.

If you cannot get both holes to align, try switching

tubes. If the holes still don’t align try switching wing

panels. If one of the tubes won’t go in quite far enough

to get the holes to align, it is okay to fi le the end of the

tube as necessary.

❏ 4. Once you have the holes in the tubes aligned

with the holes in one of the wing panels, thread 4-40 x

1" [25mm] SHCS into the wing panel and the tubes.

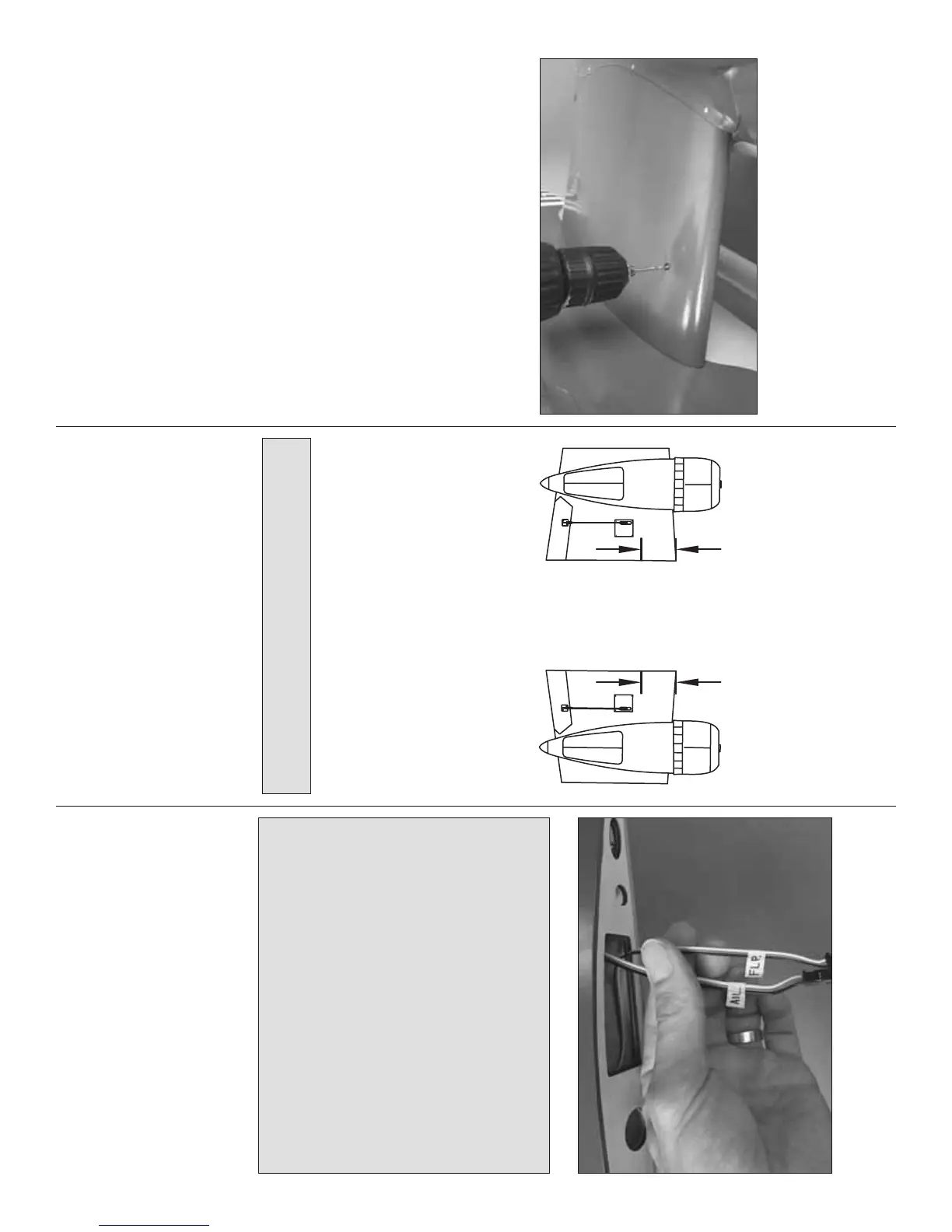

❏ 5. Tightly fi t the other inboard wing panel to the

fuselage and tubes. Using the holes in the wing panel

as a guide, drill #43 holes through both tubes.

❏ 6. Remove the panel. Use a fi ne-point felt-tip pen

to write on each tube which one is which and which

way goes up.

Loading...

Loading...