3

PLACING THE TOOL IN SERVICE

CONNECTING THE TOOL

1. Attach the twin line hose to the swivel

inlets of the low prole drive cylinder

using the spring–loaded quick connect

ends.

2. Connect the opposite ends of the hose

to the pump in the same manner.

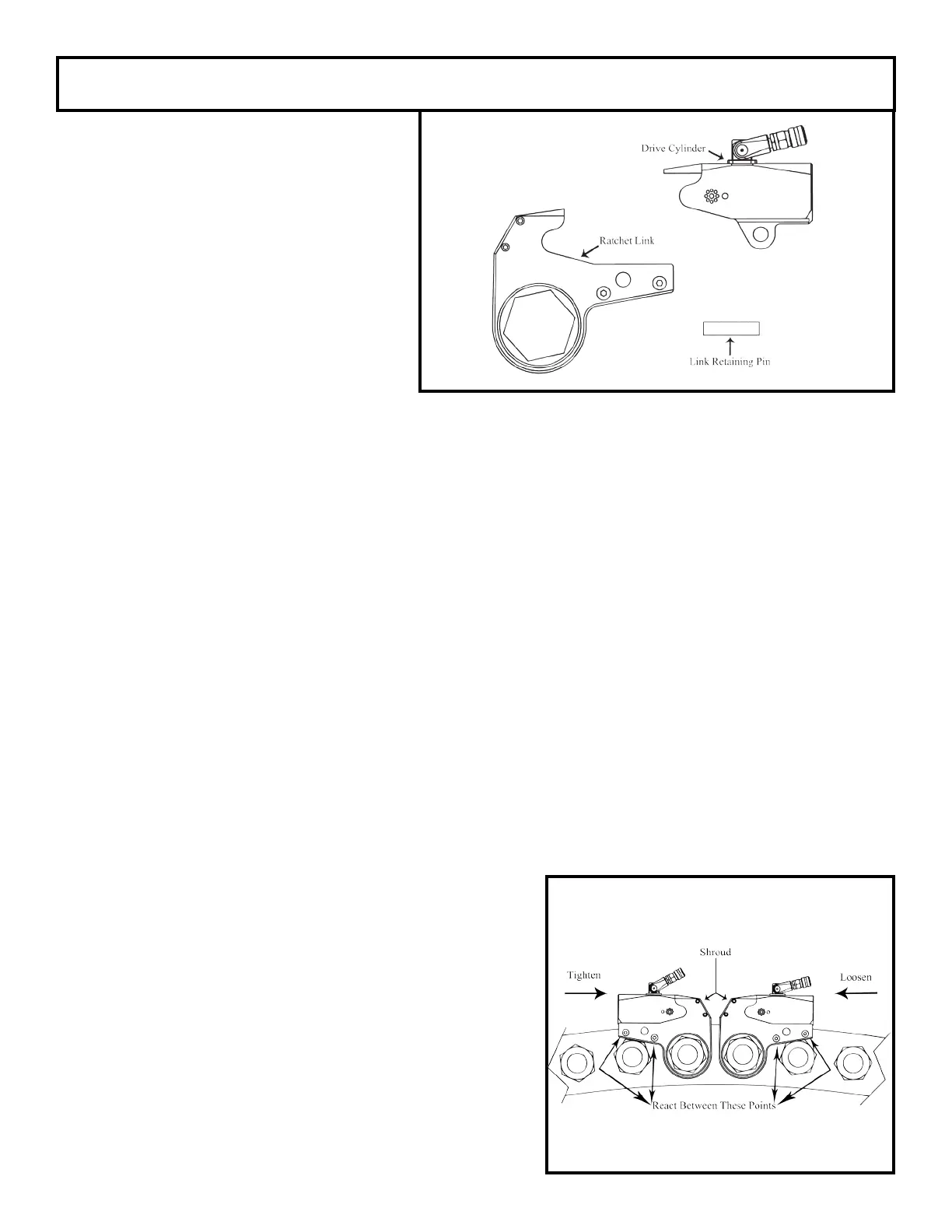

3. Push the link retaining pin out of the

low prole drive cylinder.

4. Mate the selected ratchet link to the

cylinder by inserting the end of the

cylinder opposite the swivel inlets

between the side plates of the ratchet

link. (Refer to Dwg. 1)

5. Align the holes for the link retaining pin and insert the pin through the side plates and cylinder to keep

the units joined together.

SETTING THE TORQUE

After determining the desired torque, use the torque conversion charts on pages 6 to 13 to determine the

pressure that is necessary to achieve that torque.

1. Connect the tool to the power supply and turn the pump on.

2. Depress the remote control button causing the pressure to be shown on the gauge.

3. Adjust the pressure by loosening the wing nut that locks the pressure adjustment thumbscrew.Rotate

the thumbscrew clockwise to increase the pressure and counterclockwise to decrease the pressure.

When decreasing pressure, always lower the pressure below the desired point and then bring the

gauge back up to the desired pressure.

4. When the desired pressure is reached, retighten the wing nut and cycle the tool again to conrm that

the desired pressure setting has been obtained.

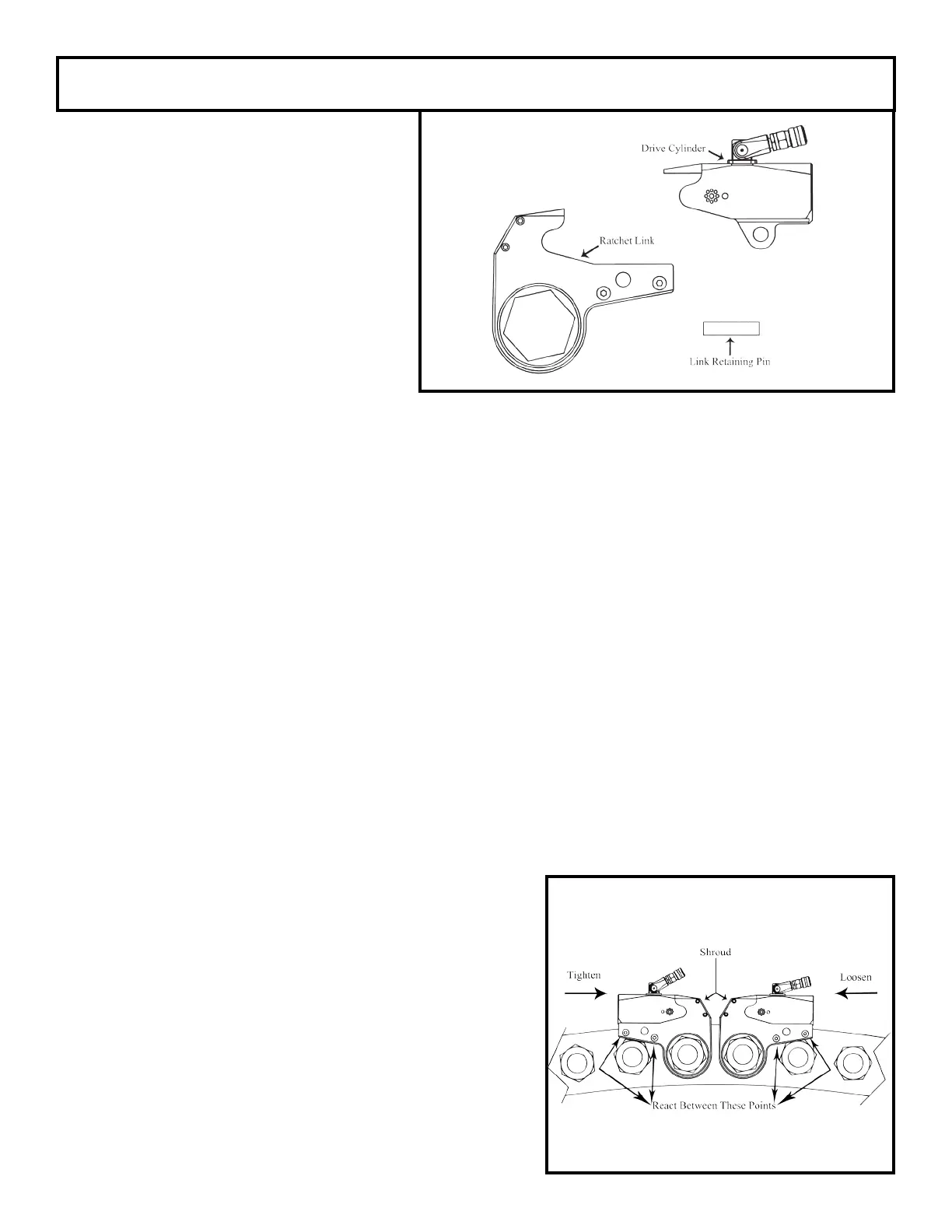

Wrench Positions Dwg. 2

OPERATING THE WRENCH

The position of the tool relative to the nut determines

whether the action will tighten or loosen the nut.

(Refer to Dwg. 2 for application examples). The power

stroke of the piston assembly will always turn the ratchet

hex toward the shroud.

1. Place the ratchet hex on the nut. Make certain it is the

correct size for the nut and that it fully engages the nut.

2. Position the reaction surface against an adjacent

nut, ange or solid system component. Make certain

that there is clearance for the hoses, swivels and inlets.

DO NOT allow the tool to react against the hoses or

swivels.

Dwg. 1

Loading...

Loading...