14

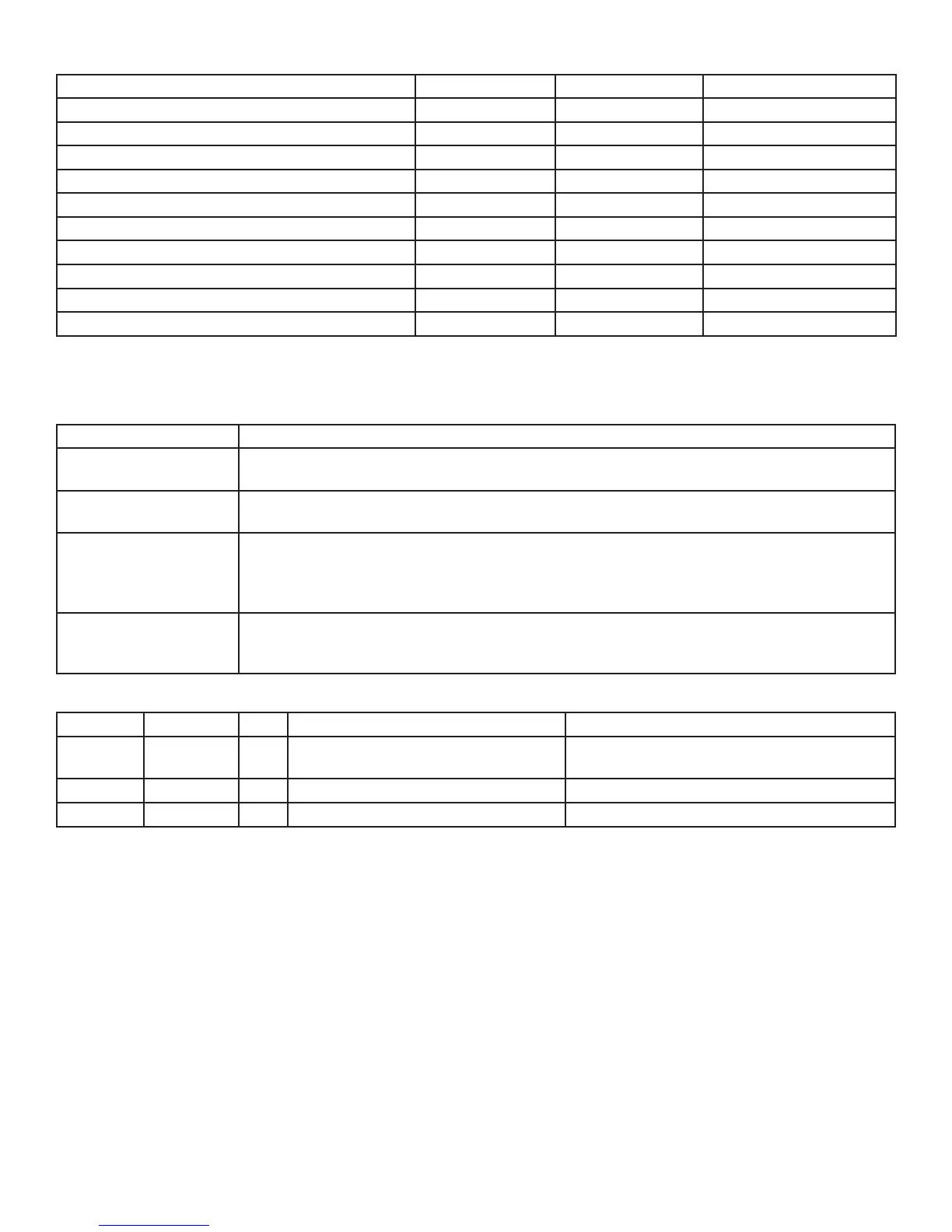

PROGRAMMED MAINTENANCE

REQUIRED ACTION DAILY WEEKLY ORDINARY/MONTHLY

RECOVERY TANK CLEANING •

SUCTION FILTER CLEANING •

BRUSH CLEANING •

BRUSH REMOVAL •

SQUEEGEE ASSEMBLY CLEANING •

FRONT SQUEEGEE RUBBER REPLACEMENT • if required

REAR SQUEEGEE RUBBER REPLACEMENT • if required

SQUEEGEE HOSE CLEANING •

SOLUTION TANK CLEANING •

SOLUTION FILTER CLEANING •

RECOMMENDED BRUSHES

Brushes must be chosen depending on the type of oor and the dirt to be removed.

The material and the bristle diameter are the elements that distinguish different types of brushes.

MATERIAL CHARACTERISTICS

PPL (Polypropylene) Good wear resistance. Maintains characteristics with hot water up to 140°F (60°C). It is not

hygroscopic.

TYNEX Nylon bristles with grains of abrasive material. Use with caution in order not to mark the oor

or ruin the nish.

BRISTLES THICKNESS Thicker bristles are more rigid and must be used on smooth oor or oor with small joints. On

irregular oors with deep joints or relieves, softer bristles penetrate more easily and deeper.

Please be aware that when brush bristles are worn out they become rigid and unable to pen-

etrate and clean deeper. This may also cause brush vibration with thicker bristles

PAD HOLDER Pads are recommended to clean smooth surfaces. The pad holder has anchor points to retain

the pad. It is important that the height of the pad holder with its pad is the same as the one of

the brush.

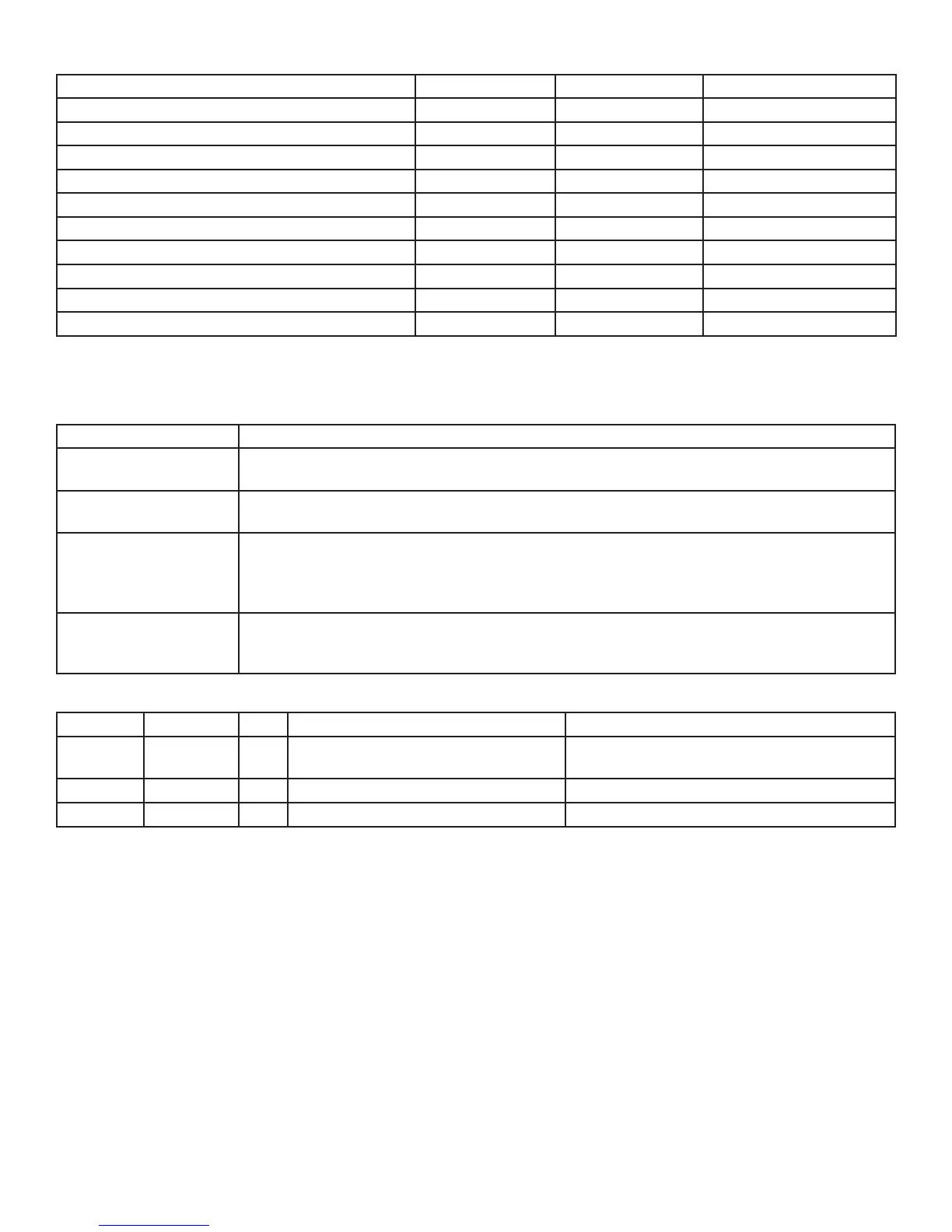

MACHINE PART NO. QTY DESCRIPTION USE

BD 17/6 48903130 1 Brush PPL 0,9 Ø 430 Floors of resistant material and particularly

dirty.

48903150 1 Brush 5-mix Ø 430 For all types of oors.

48803050 1 Pad holder Ø 425 + center lock green For pads of 17”, for smooth surfaces cleaning.

Loading...

Loading...