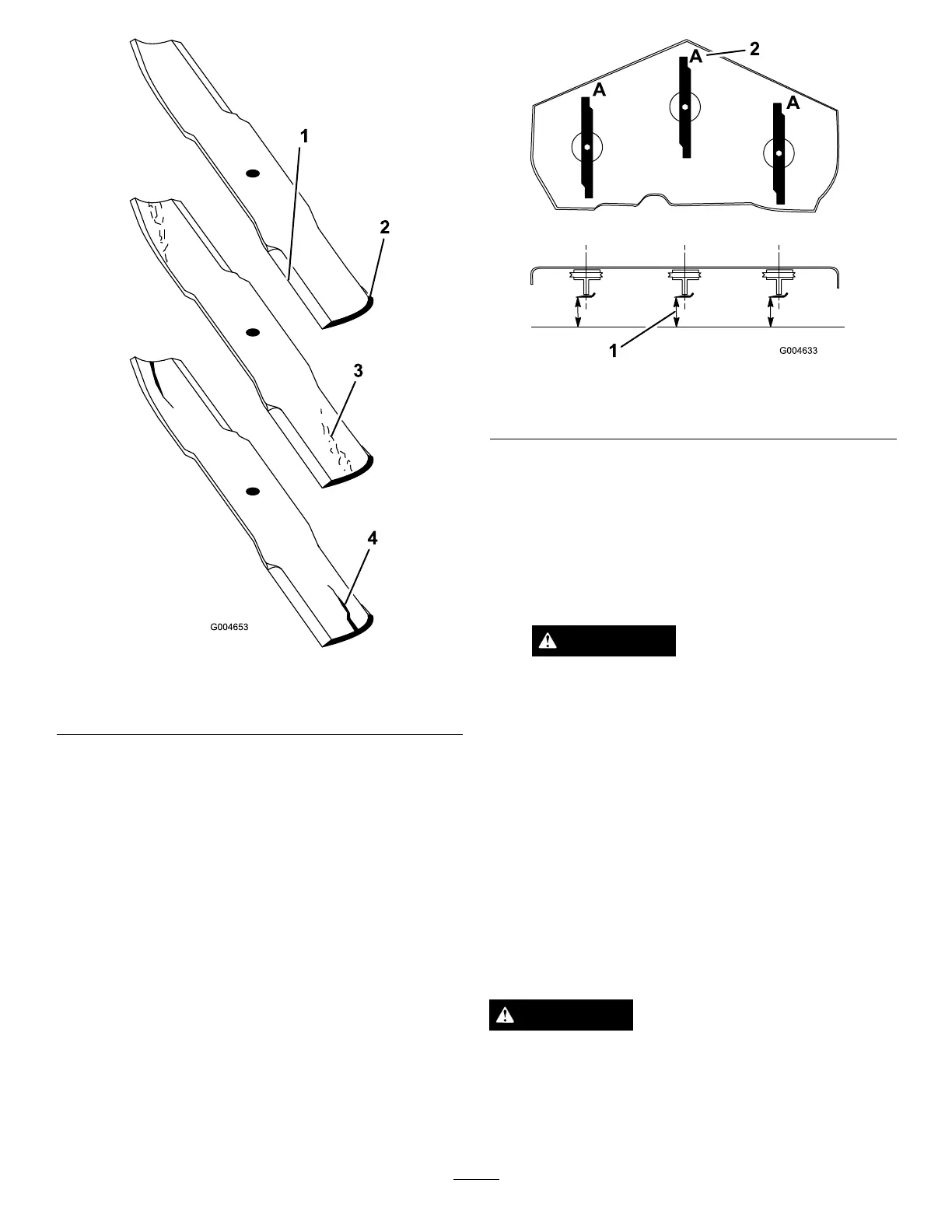

Figure65

1.CuttingEdge3.Wear/slotForming

2.SailArea4.Crack

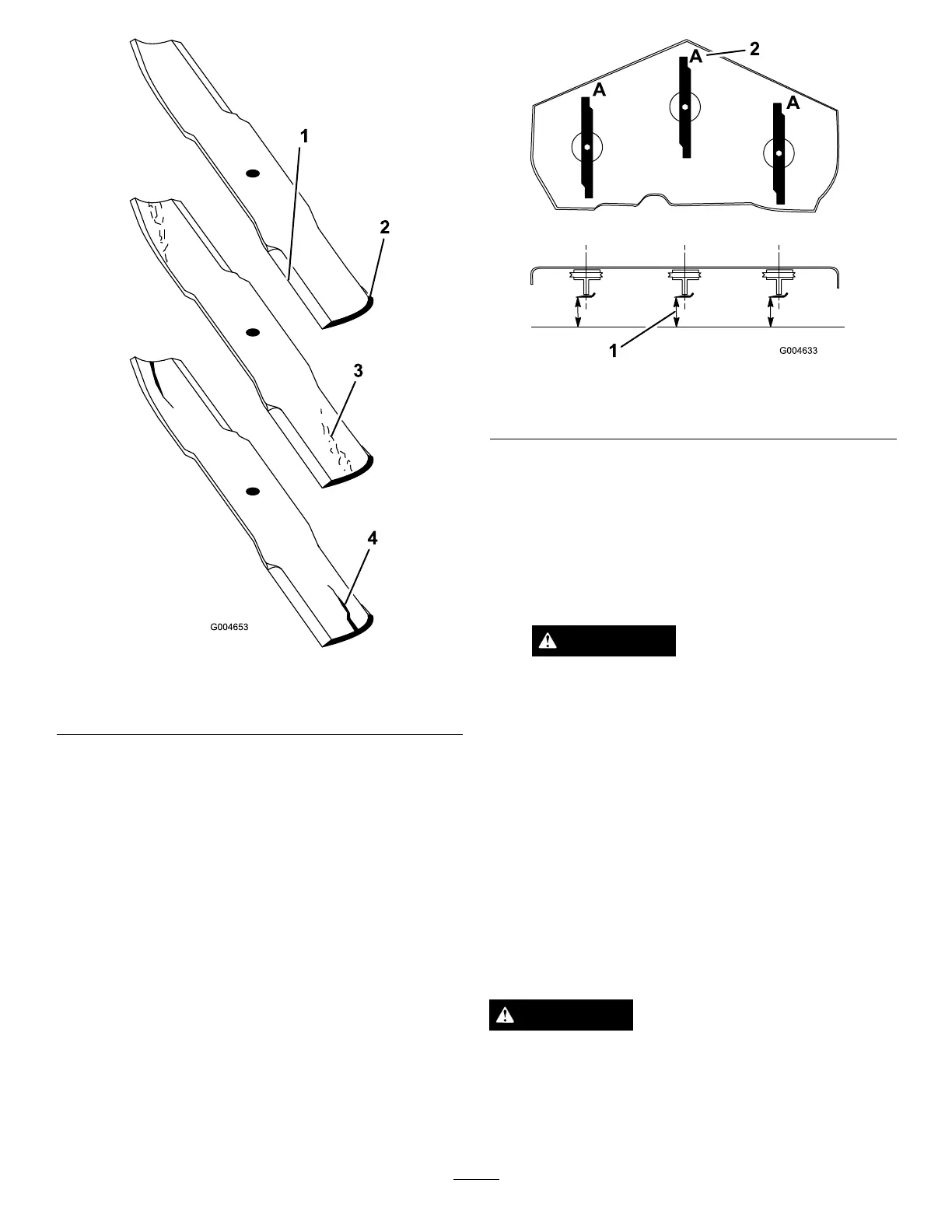

CheckingforBentBlades

1.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward(

Figure66).Measurefromalevelsurfaceto

thecuttingedge,positionA,oftheblades(Figure66).

Notethisdimension.

Figure66

1.Measureherefromblade

tohardsurface

2.PositionA

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep3above.

Thedifferencebetweenthedimensionsobtainedin

steps3and4mustnotexceed3mm(1/8inch).Ifthis

dimensionexceeds3mm(1/8inch),thebladeisbent

andmustbereplaced;refertoRemovingtheBlades

andInstallingtheBlades.

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalanceorisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineTororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

WARNING

Contactwithasharpbladecancauseseriousinjury.

Wearglovesorwrapsharpedgesofthebladewith

arag.

1.Holdthebladeendusingaragorthickly-paddedglove.

57

Loading...

Loading...