Maintenance

MaintenanceSafety

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Allowthemachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringit.

•Disconnectthespark-plugwirefromthesparkplug

beforeperforminganymaintenanceprocedure.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Keepallnuts,boltsandscrewstighttoensurethat

themachineisinsafeworkingcondition.

•Replaceafaultymufer.

•Tippingthemachinemaycausethefueltoleak.

Fuelisammableandexplosive,andcancause

personalinjury.Runtheenginedryorremovethe

fuelwithahandpump;neversiphonthefuel.

•Inspectthemachineregularlyandreplacewornor

damagedparts.Ensurethatpartsarenotbent,

damaged,orloose.

•Toensureoptimumperformanceofthemachine,

useonlygenuineTororeplacementpartsand

accessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous,

andsuchusecouldvoidtheproductwarranty.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst20hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengine-oillevel.

•Cleandebrisfromcoolingns,airinletsandlinkages.

Every25hours

•Servicetheaircleaner(moreofteninextremelydustyconditions).

•Changetheengineoilwhenoperatinginhightemperaturesorunderheavyloads.

Every50hours

•Changetheengineoil.

•Checkthesparkplug.

Pre-Maintenance

Procedures

PreparingforMaintenance

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Disconnectthespark-plugwirefromthespark

plug.

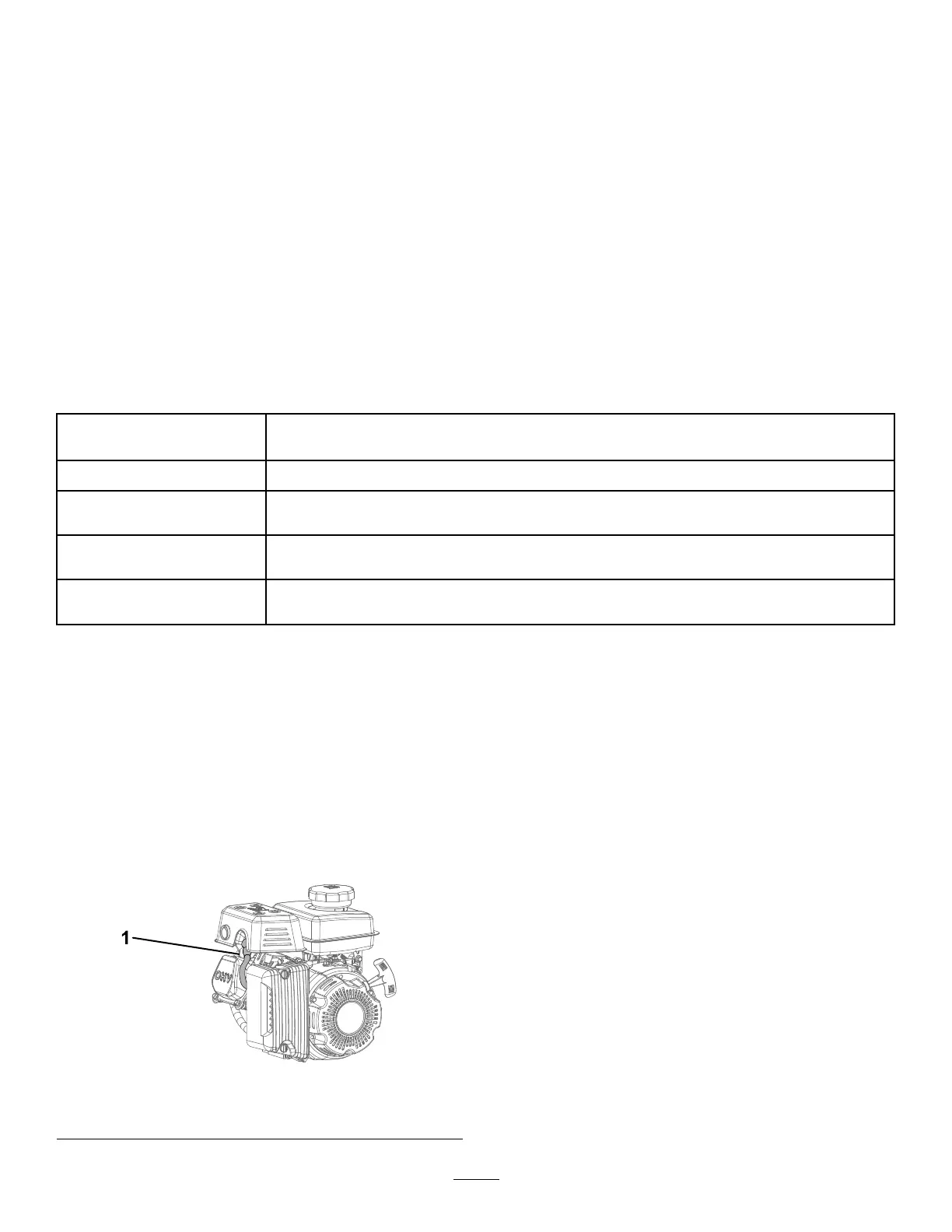

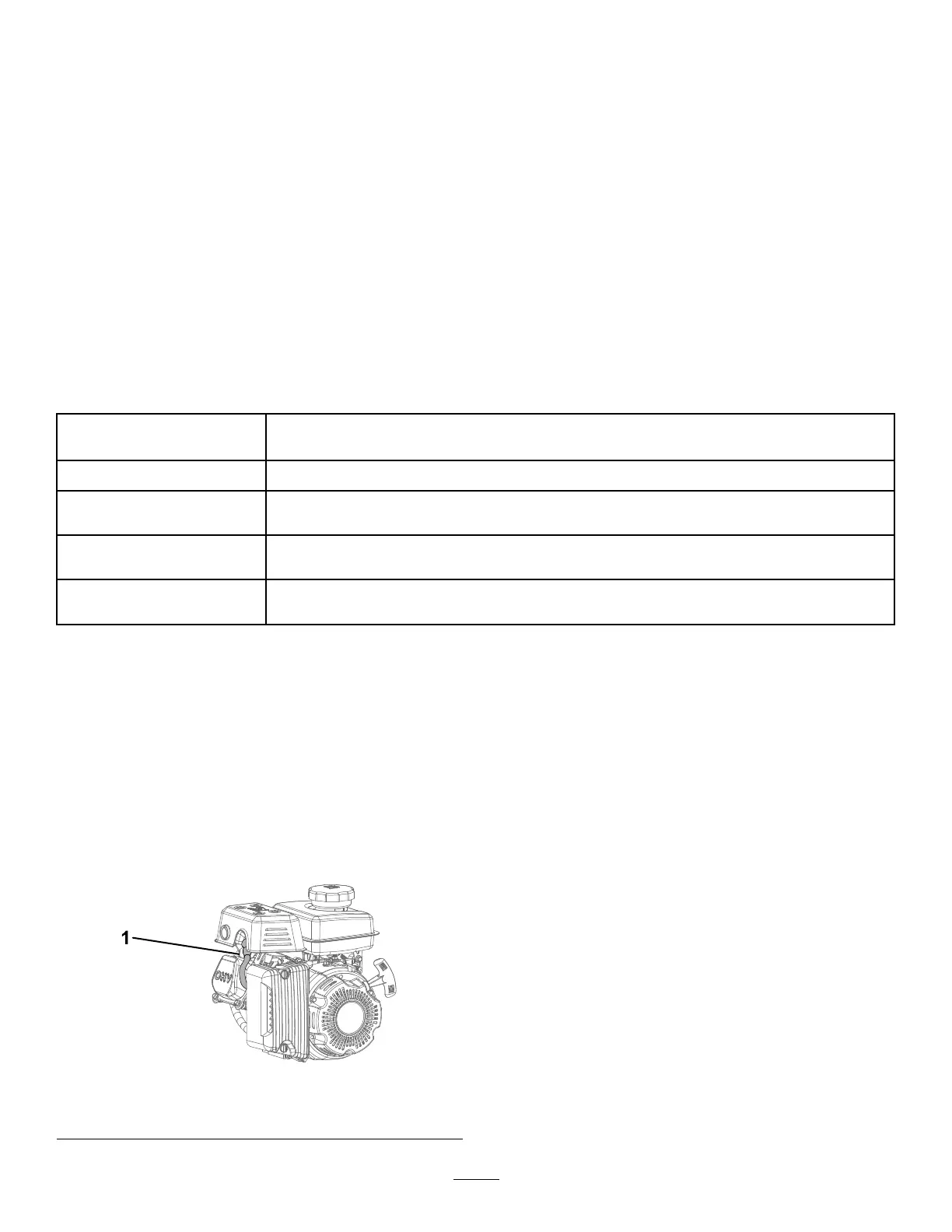

g385624

Figure16

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

Important:Beforetippingthemachine,

allowthefueltanktorundrythroughnormal

usage.Ifyoumusttipthemachinepriorto

runningoutoffuel,useahandfuelpumpto

removethefuel.

17

Loading...

Loading...