Maintenance

32

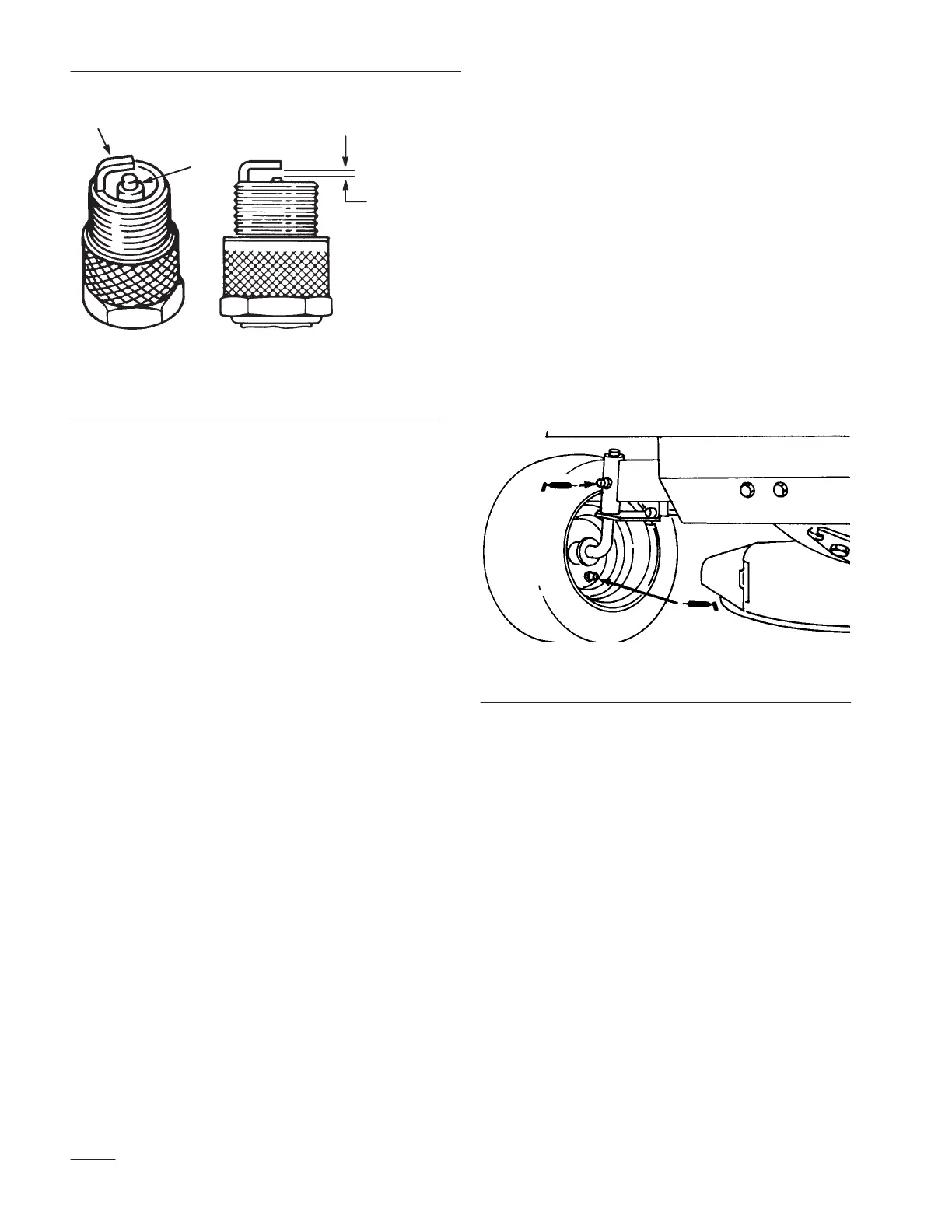

0.030”

(.762 mm)

2

3

1

Figure 13

1. Center electrode insulator

2. Side electrode

3. Air gap (not to scale)

Installing the Spark Plug(s)

1. Install the spark plug. Make sure the air gap is

set correctly.

2. Tighten the spark plug(s) to 15 ft-lb (20.4 Nm).

3. Push the wire(s) onto the spark plug (Fig. 12).

Greasing and Lubrication

Service Interval/Specification

Grease the machine after every 50 operating hours or

yearly, whichever occurs first. Grease more frequently

when operating conditions are extremely dusty or

sandy.

Grease Type: General-purpose grease.

How to Grease

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. Clean the grease fittings with a rag. Make sure to

scrape any paint off the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease

into the fittings until grease begins to ooze out of

the bearings.

4. Wipe up any excess grease.

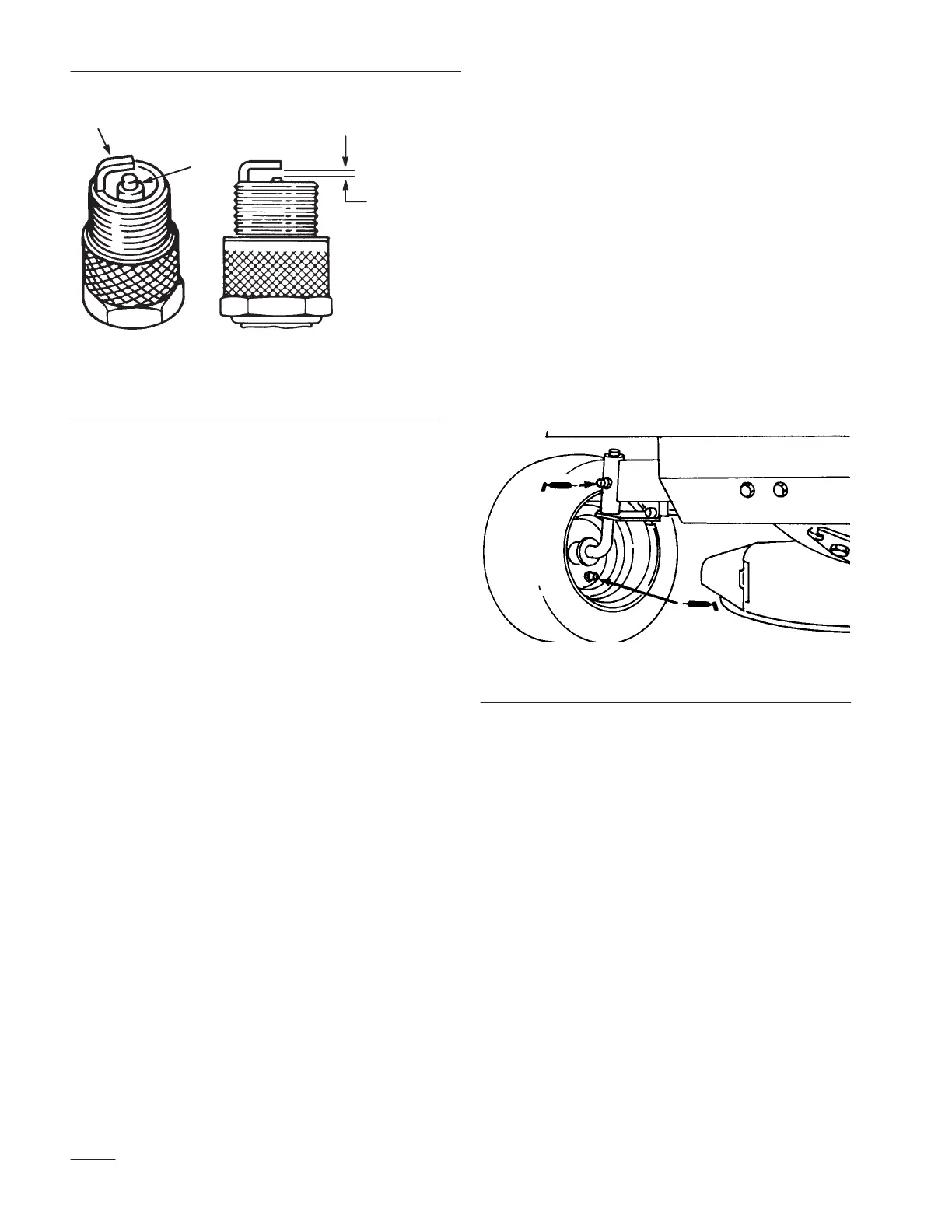

Where to Add Grease

1. Lubricate the front wheels and spindles until

grease begins to ooze out of the bearings

(Fig. 14).

Figure 14

2. Grease rear axles with one to two pumps of No.

2 general purpose grease. The zerks are located

just inside of the rear tires on the bottom of the

transaxle (Fig. 15).

Lubricate Pivot Points

The mechanical pivot points on the rider must be

oiled after every 25 hours of operation; lubricate more

frequently when conditions are dusty or sandy.

1. Oil pivot points of steering, drive, brake, clutch,

and deck engagement linkage with light oil

(Fig. 15). Wipe up any excess oil.

Loading...

Loading...