DriveSystem

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Adjustthehandleneutralandhydraulic

pumpneutralbeforeadjustingthetracking.Refer

toAdjustingtheHandleNeutralandAdjustingthe

HydraulicPumpNeutral.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Unlatchtheseatandtiptheseatuptoaccessthe

pumpcontrolrod.

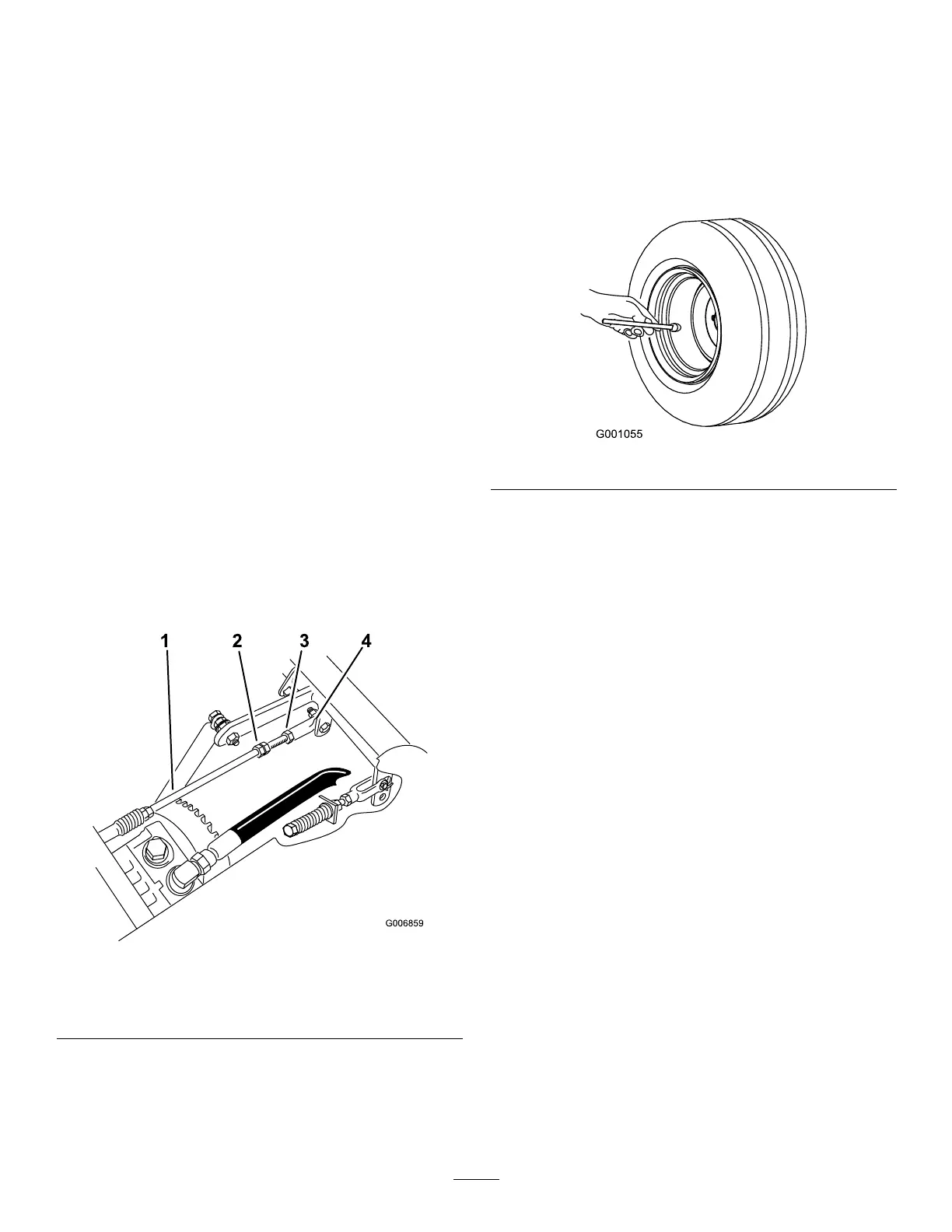

4.Loosenthelocknutattheballjointonrighthand

pumpcontrolrod(Figure42).

•Tomakethemachinegoright,rotatethedouble

nutsonrodtotherightsideofthemachine.

•Tomakethemachinegoleft,rotatethedouble

nutsonrodtotheleftsideofthemachine.

5.Tightenthelocknutattheballjointandtestthe

tracking(Figure42).

6.Repeatthisadjustmentuntilthetrackingiscorrect.

Figure42

1.Righthandpumpcontrol

rod

3.Locknut

2.Doublenuts4.Balljoint

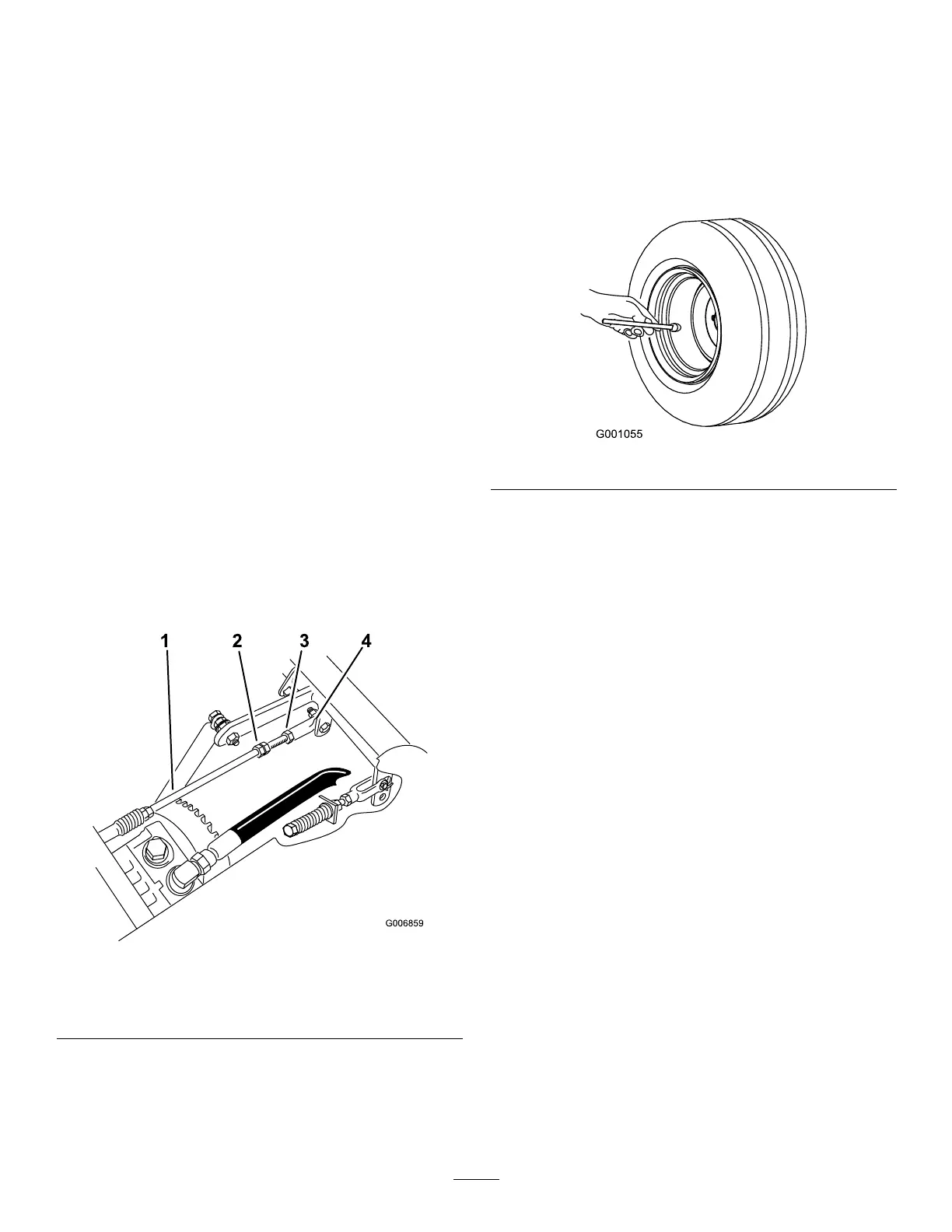

CheckingtheTirePressure

ServiceInterval:Every50hoursormonthly,whichever

occursrst.

Checkthepressureatthevalvestem(Figure43).

Maintaintheairpressureinthereartiresat13psi(90

kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure43

CheckingtheWheelHub

SlottedNut

ServiceInterval:Every100hours

Theslottednutneedstobetorquedto125ft-lb

(170N⋅m).

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethecotterpin.

4.Torquetheslottednutto125ft-lb(170N⋅m)

(Figure44).

37

Loading...

Loading...