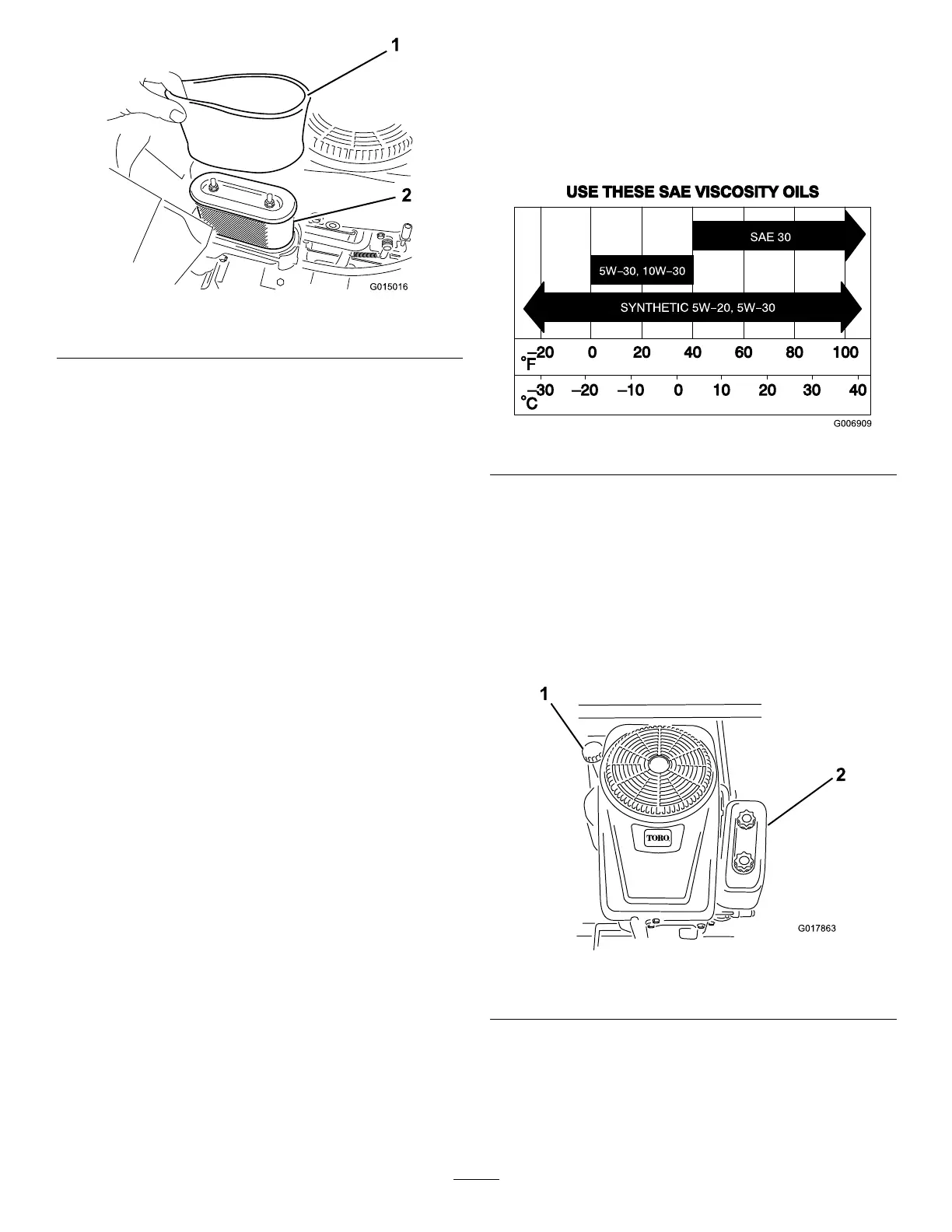

Figure28

1.Foamelement2.Paperelement

6.Separatethefoamandpaperelements.

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.Do

notoiltheelement.

Important:Replacethefoamelementifitistorn

orworn.

3.Installthefoamelementonacleanpaperelement.

PaperElement:

1.Tapthepaperelementonasolidatsurfaceandblow

itoutfromtheinsidewithcompressedairtoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totherubberseal.

Important:Donotcleanthepaperelement

withpressurizedairorliquids,suchassolvents,

gasoline,orkerosene.Replacethepaperelement

ifitisdamagedorcannotbecleanedthoroughly.

3.Cleantheinsideoftheaircleanercoverofalldirt,dust,

anddebris.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure28).

2.Installthefoamandpaperlterontotheaircleaner

housing.

3.Installtheaircleanercoverandtightenthetwoknobs

(Figure27).

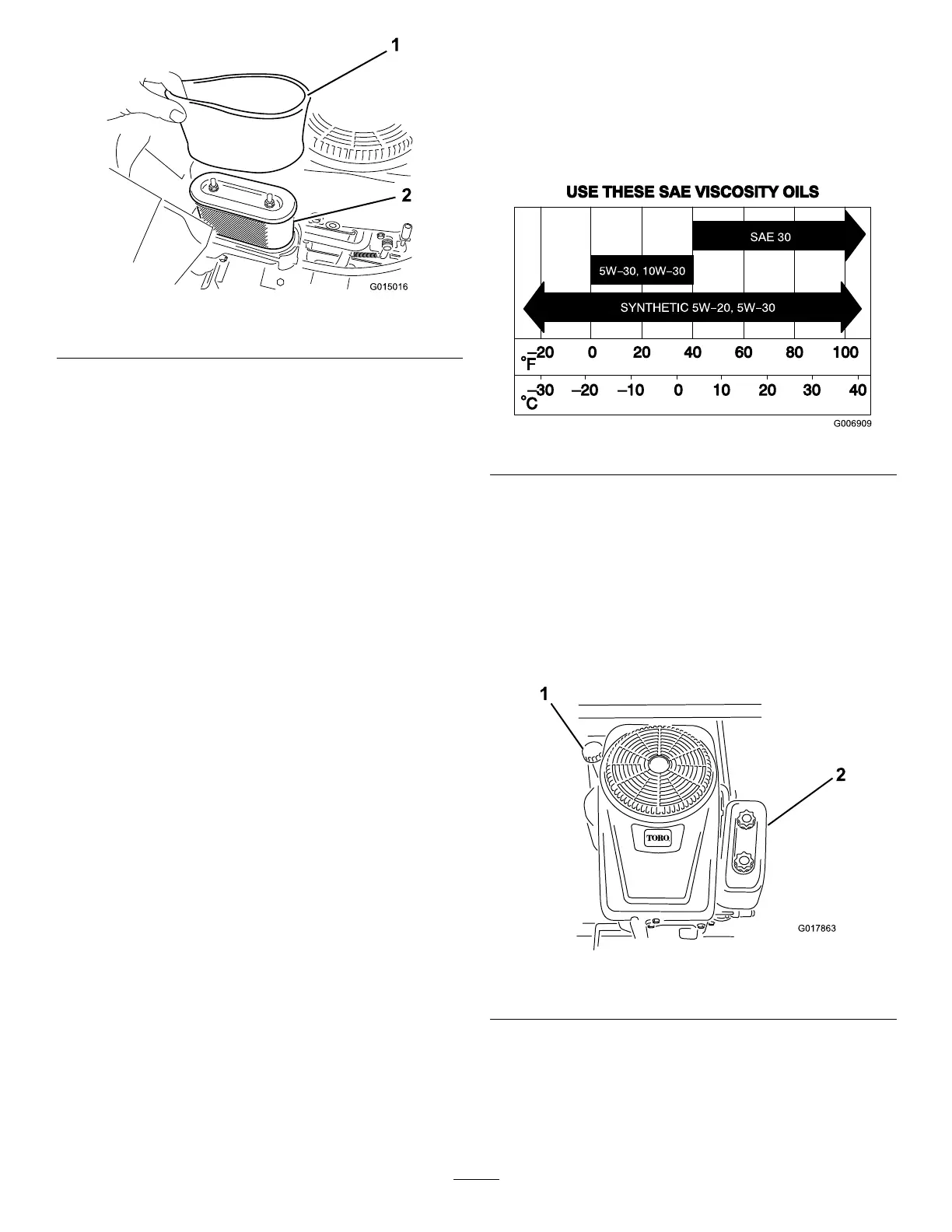

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,orhigher)

CrankcaseCapacity:34ounces(1.0l)whenyoudonotchange

thelter;36ounces(1.05l)whenyouchangethelter.

Viscosity:Seethetablebelow.

Figure29

CheckingtheOilLevel

1.Parkthemachineonalevelsurface.

2.Disengagethebladecontrol(PTO).

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Cleanaroundtheoildipstick(Figure30)sothatdirt

cannotfallintothellholeanddamagetheengine.

Figure30

1.Oildipstick/llhole

2.Aircleaner

5.Unscrewtheoildipstickandwipetheendclean.

6.Screwtheoildipstickfullyontothellhole.

7.Unscrewthedipstickagainandlookattheend.Ifthe

oillevelislow,slowlypouronlyenoughoilintothell

holetoraisetheleveltotheFullmarkonthedipstick.

24

Loading...

Loading...